It was to be my first day underground at Middleton Broom Colliery, Leeds. Tommy C., George L and George O’ N. and I were to be taken on a tour of the underground workings with Bennie W. We had been instructed to go to his office at 9 o’clock on our first Monday. When we duly reported we were informed that Benny was already underground attending to another matter. We were to make our own way and meet him at the pit bottom.

Booking out lamps, we went to the man riding shaft. There we were informed that the shaft was undergoing maintenance, all man riding would temporary have to use the other shaft. We walked round and climbed up the steps to the coal shaft pit bank.

Whilst waiting, with others, the banksman, who knew that it was our first time down Middleton said. “First time down eh lads; I’ll have a word with the winder to let you down steady”. He had a slight smile on his face.

As I have prior explained the man riding shaft was electrically driven and governed to restrict the speed of descent. The cage we were about to enter was steam driven and greater speed could be used.

The time came for us to descend, the banksman ‘rang’ the cage off and we began our descent. Suddenly the speed of descent greatly increased until it felt as if it was out of control. The weight of my body seemed to decrease. Never had we travelled any way near as fast when descending the Lofthouse Colliery. I was truly frightened, but the others riders in the cage did not seem unduly perturbed. We reached the bottom with a juddering halt. The others alighted as if nothing had happened and I was glad to get out in one piece. George L. looked as white faced as I felt. I was to find in later rides that it was quite normal to ride fast down the coal shaft whereas the electric driven, man rider was quite smooth and comparatively slow.

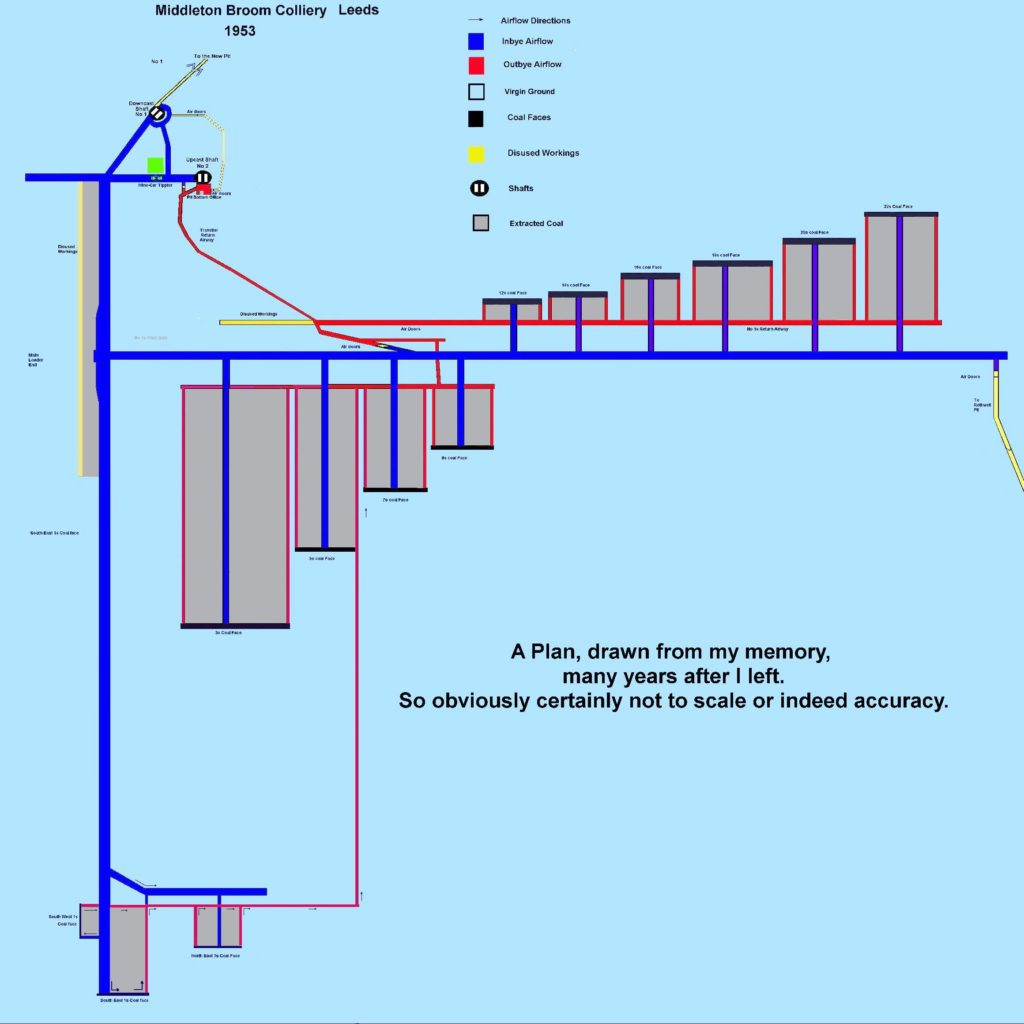

Benny W. met us, as promised at the pit bottom. After telling us to hand our checks to the onsetter he led us out of one of the exit tunnels. Ben explained that he was to take us to one of the numerous ‘faces’ of the seam. He told us that there were six faces in operation at that time. He would show us the workings of the face and we would then follow the progression of the coal as it was extracted out of the pit.

We walked down roadways varying from twelve to six feet in height for about three miles. Evidence of the weight of the forces acting on the steel ring supports was evident, especially in the tail gate we visited.

On our travels inward Bennie explained the working of a pit, in particular Middleton. He explained:

A seam of coal can be imagined as the filling in a sandwich. The bread above and below is the rock, with the filling, coal, in the middle; the area of coal can be tens of miles square. Due to rock Strata faults, the workable ‘Ebor’ seam at Middleton had about four miles of square area. The coal seams can vary in height from pit to pit. At Middleton the average height is two feet and a few inches thick. Other pits boasted seams of four to five feet.

He went on that to describe a coal face. It was easier to think of a plan view of the capital letter E. With a piece of chalk, (all Deputies and management carry a piece of chalk) he drew an end on letter E with the legs pointing downwards. The centre leg of the E he called the main gate and the outside legs were the two tail gates. The coal face was the long upright of the E. Coal face lengths vary; an average distance between a Tail gate and a Loader gate is some eighty yards (73m). The left and right faces combined at around one hundred and sixty yards (146m) or more. The main gate usually is about 9 foot (3m) in height and the two tail gates Six foot (2m).

Longwall or forward mining was the extraction method of coal used at Middleton Colliery. (A different method is now more commonly used, called retreat mining). He further explained that at the start of a new coal face the main gate and the two tail gates are driven forward about fifty yards (50m). The coal, in between the gates is called a pillar. This pillar is left intact to protect the main heading gate from excess weight.

The coal is hand hewn and blasted out with explosives, at right angles to both left and right sides of the main gate. A coal face heading can also be started from the tail gates driven towards the main gate. Only about nine feet (3m) width of coal is taken. The rock above the coal is the roof. The face headings meet somewhere in the middle, with little more than a few inches (5cm) out of alignment; great accuracy is achieved due to the mine survey department.

The coal or the strata under the coal is then undercut by a machine, the jib that is at right angles to the machine. The jib has a fast continuous rotating chain with protruding tungsten carbide tipped picks. The jib of the machine is about six feet (2m) long.

Holes are drilled in the face of the coal to a depth of about six feet deep, at six foot intervals. A conveyor, or what is commonly called the ‘belt’, is then installed the whole length of the face. ‘Chocks’ which are extra roof supports are set at the roof break off point. When all tasks are completed and running, a shotfirer will stem the drilled holes with an explosive charge and ‘fire’ the ‘shots’.

Miners will then space themselves out along the face and begin to hand shovel the loosened coal on to the conveyor belt. A short pick would also be used to hew coal from the face that has not been loosened by the explosives. Wood props and bars would be set to contain the new exposed roof as the coal was shovelled on to the conveyor. The coal cutting machine would be turned around in one of the Tail gate ‘corners’ and a new cut started to begin the whole process again.

As the face moves forward, six feet per day, the void left becomes what is called the ‘Gob’. All supports were, or should be, withdrawn from the gob area. The gob roof then falls in, relieving the weight on the face roof. All waste material is deposited or thrown into the gob. Compacted stone packing were built in the gob at either side of the gates. This packing helps to take some of the weight from the gate supports.

The whole process from the cutting of the coal to the hand extraction of it was designed to take twenty four hours. When all worked perfectly it did, which was not all too often.

Bennie throughout our journey continued to explain:

The coal from the face conveyors fed on to the gate conveyor. Each gate conveyor in turn led on to series of larger width main gate conveyors. At each conveyor machine station, a worker was placed to ensure that the conveyor belt can be controlled. His job is to turn the conveyor on or off as required and to keep the area free from accumulating spillage falling from the belt.

When we reached the end of the conveyor system the coal tumbled into minecars. The minecars were slightly smaller that the ones at Lofthouse and held about two and a half tons of coal each. This point was called the loader end. The Safety Officer told me this was to be my place of work on the following day.

He introduced me to a youth called Douglas G. He did not look much older than me; it turned out that he was about six months older. I was told that I was to be under the charge of Doggie for a period of three weeks. I was to be within hailing distance of him at all times during that period. After this probationary period I would be on my own and could be placed anywhere in the pit that I was trained for.

We followed the trail of the loaded minecars up the main heading. They were hauled to the pit bottom by a diesel engine locomotive. George L. was to be a diesel driver’s mate. At the end of the Main heading there was a huge tippler that rotated the mine cars to empty them.

The coal was then fed again on to a short conveyor. There it was loaded in to the smaller tubs that I had handled on the surface at the pit bank. The tubs were then pushed on rails round to the shaft cage, in turn to be loaded in to it for transport to the surface.

Ben W. then took us to visit the stables. Tommy C. and George O’N. were introduced to the stable manager, Alfred Day, for their three weeks supervision. They were to become pony drivers.

Go to Next Chapter or Index