<This page is a work in progress, please check back later>

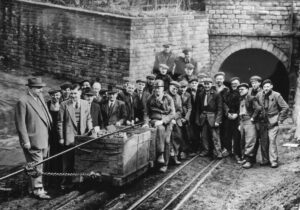

Thorncliffe Drift 1955

The last run of coal hauled from the Thorncliffe Drift was on the 2nd of April 1955. The front man sitting on the run is George Albert North, the oldest employee aged 72. © Terry Bintcliffe collection

Thorncliffe Colliery was situated some 5½ miles north of Sheffield within the boundary of the Thorncliffe Ironworks.

Following the opening of the railway, Newton & Chambers & Co and Earl Fitzwilliam embarked upon a joint venture to de-water the workings of their adjoining mines. Work on the Thorncliffe/Elsecar Drift (or sough) was commenced on 18th December 1839, from Skiers Spring and extended for 600 yards, to the Parkgate Seam at Thorncliffe.

The original pits at Thorncliffe were accessed via drifts and later by shafts, with interconnecting passages underground, for ventilation and pumping purposes. In 1842, Thorncliffe was working a drift in the Parkgate Seam and in 1854, a new 1 in 10 surface drift, to work the Parkgate Seam, was commenced from the edge of the woods, within the boundary of the Thorncliffe Ironworks. Driven in an easterly direction, the drift was known as Thorncliffe Main Colliery, because it was planned to become the main production site for the ironworks complex.

<—>

In 1896, the main drift had increased in length to 1100 yards. Thorncliffe Main employed 495 men and boys underground, 169 on the surface and produced 700 tons of coal per day. The coal was hauled to the surface by a steam-powered, over-tub, endless rope.

<—>

In 1914, the 12-foot diameter Barley Hall Shaft was incorporated into the Thorncliffe Main ventilation system as the new upcast shaft, replacing the Guibal fan in the main drift. The Bailey Hall site was electrified and the Shaft was used to wind men and materials to the Silkstone Seam, saving a 1½ mile walk from the mouth of the Thorncliffe Drift.

In 1924, two new surface drifts were opened at the Colliery. The New Silkstone Drift, dipping at 1 in 10, was driven within the ironworks boundary, to access the Silkstone Seam. The second drift, sited near the Barley Hall Shaft, was a 305-yard long intake drift, at a 1 in 4 gradient, to the Parkgate Seam.

In 1933, Thorncliffe employed 900 men underground, 327 on the surface and was working the Parkgate, Silkstone and Fenton Seams. The Fenton Seam had been accessed via the 1924 New Silkstone Drift and connections had been made in-seam to the Skiers Spring Shaft at Rockingham. Both the Fenton and Silkstone Seams were fully mechanised. In 1939, pit head baths with facilities for 750 men were opened at the Barley Hall Shaft site. During 1940, manpower at the Colliery had fallen to 700 underground and 450 on the surface, due to enlistment in the armed forces.

In 1946 Thorncliffe Colliery was producing 4000 tons of coal per week from the 36 inch thick Fenton Seam at a depth of 248 yards and the 27 inch thick Silkstone Seam at a depth of 305 yards. The 26 inch thick Whinmoor Seam was being developed and was due to start production in the near future. Coal was hauled up the Parkgate and New Silkstone Drifts at Thorncliffe. These drifts and the Wembley Drift at Barley Hall formed the 3 intakes for the Colliery. The Barley Hall upcast shaft had been deepened to a new sump depth of 270 yards and provided upcast ventilation for the Whinmoor Seam, from an inset at 223 yards. The Colliery had 3 pumping shafts, at Tankersley, Barley Hall and Skiers Spring.

On Nationalisation in 1947, Thorncliffe Colliery, including the Barley Hall site became part of the NCBs Northeastern Division, No5 South Barnsley Area and employed 515 men underground and 169 on the surface, working the Fenton, Parkgate, Silkstone and Whinmoor Seams.

Thorncliffe Colliery closed in 1955 and the workforce transferred to Barley Hall shaft which became Barley Hall Colliery.

Return to previous page