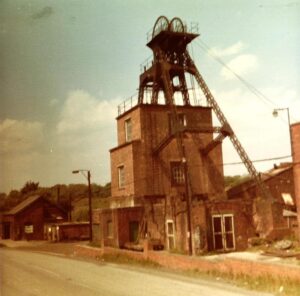

Barley Hall Colliery was located close to the village of Thorpe Hesley, about 6 miles north of Sheffield.

Sinking the 12-foot diameter shaft was commenced in June 1886 and reached the Silkstone Seam at a depth of 165 yards in January 1887. Although the shaft had been sunk, Barley Hall did not become a colliery in its own right until 1955. A Walker ventilating fan was installed to draw fresh air through the workings from the nearby Norfolk Colliery.

In 1890, a new drift mine, Smithy Wood Colliery, was opened to work the Thorncliffe Thin and Silkstone Seams. Barley Hall became the upcast shaft for that Colliery as well as Norfolk Colliery. From 1914, the Barley Hall Shaft became the upcast and service shaft for Thorncliffe Colliery. The Walker fan was electrified and an electric winding engine to haul single-deck cages was installed. The Shaft was then used to wind men and materials to the Silkstone seam. It was also used to pump water from the old Norfolk Colliery workings.

In 1924 a 305 yard long inclined drift was driven at a gradient of 1 in 4 to the Parkgate Seam as a second intake for the Thorncliffe Colliery. This drift was named the Wembley Drift after the stadium opened at Wembley in London the same year. By 1927, Barley Hall was one of a number of sites used as pumping stations for the Thorncliffe Colliery, the others being Tankersley & Thorpe Hesley Collieries and Bradgate Drift. In 1939, pit head baths were installed catering for up to 750 men

In 1946 the Barley Hall shaft was deepened to 270 yards with a pit bottom at 233 yards for the Whinmoor Seam. This 31 inch seam was first discovered in 1893 in the Tankersley Colliery and preparations were made to start working it at Thorncliffe Colliery.

New Silkstone Drift Early 1940s

New Silkstone Drift at Warren Bridge, Thorncliffe. Known as “The Wembley”. The drift was driven alongside the Thorncliffe Main Drift in 1924 and closed in the late 1940s. This photo of the haulage workers was taken at Barley Hall Plain in the early 1940s. On the left, Ned Denton loosing off a full set of tubs. On the right, Herbert Bartlet is hanging on the back chain of a set of empty tubs going inbye. © Terry Bintcliffe collection

On Nationalisation in 1947, Thorncliffe Colliery, including the Barley Hall site became part of the NCBs Northeastern Division, No5 South Barnsley Area and employed 515 men underground and 169 on the surface, working the Fenton, Parkgate, Silkstone and Whinmoor Seams.

Thorncliffe Colliery closed in 1955 and the workforce transferred to Barley Hall which became Barley Hall Colliery. Production from the Whinmoor Seam ended in 1958.

In 1962, the NCB Yorkshire Division was formed, and Barley Hall Colliery was placed in South Barnsley Area Group C, along with Rockingham and Smithy Wood Collieries. The nearby Grange Colliery was marked for closure and from 1961 a large number of its workforce was transferred to other collieries, particularly Barley Hall. From that time, Barley Hall was producing between 200,000 and 250,000 tons of coal per year and employing upwards of 400 men.

From 1963, the Wembley Drift was no longer used to bring coal to the surface because an underground connection with Smithy Wood Colliery was used to send Barley Hall coal directly to the Smithy Wood surface.

The Silkstone Seam was abandoned in February 1968 and the Thorncliffe Seam in January 1970. Following the closure of Smithy Wood Colliery in December 1972, Barley Hall coal was conveyed underground to Skiers Spring Colliery (part of Rockingham Colliery) for onward movement to the Processing Plant at Smithy Wood, which remained open.

In March 1973 the colliery employed 374 men and produced 232,000 tons of coal from the Fenton Seam, however on 31st May 1974, Barley Hall Colliery was closed due to exhaustion of its reserves. At closure, 380 men were employed, of these 250 were transferred to local collieries and 130 were made redundant.

More photos from the Terry Bintcliffe collection can be found in the Members Area

Return to previous page