General view of Frickley-South Elmsall Colliery from the east 1972 No.3 Shaft (South Elmsall) to left. No.1 Shaft, coal winding & downcast, in centre. No.2 Shaft (downcast & man riding) to right. Screens in foreground and washery to right.

Left: Screens with rapid loading bunker behind. Centre: stores, No.2 winder and shaft (upcast & man riding). Right: workshops. 1972

Entrance to lamp room 1972

Rapid loading bunker 1972

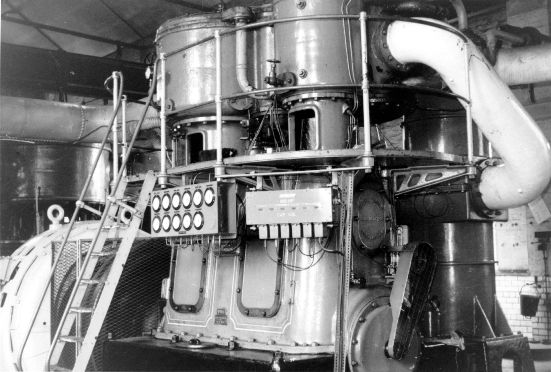

Bellis and Morcom air compressor, serving Frickley pit 1972

All photos courtesy of Mike Gill

The Carlton Main Colliery Co. Ltd began sinking two, seven metre diameter shafts in March 1903 and completed them on May 24th 1905, having reached the Barnsley seam at a depth of 608 metres. The latter was three metres thick, but only the lowest 1.8 metres were worked. Ventilation was from a 7.3 metres in diameter Walker fan on No.2 Shaft. Coal winding was done at No.1 Shaft, which served as downcast. The same company worked the colliery until Nationalisation on January 1st 1947. The National Coal Board worked it until 1987, when the British Coal Corporation took over the remaining nationalised pits.

Rail links were made with the Midland & North-East Railway Companys’ Swinton & Knottingley Joint Line and through the London North Eastern Railways’ Wath Branch to its line from Wakefield to Doncaster. By the late 1960s a Rapid Loading bunker had been built to serve Merry-Go-Round trains running to local power stations.

The Dunsil seam, 12 metres below the Barnsley, was worked from 1925 until 1931, when lack of quota led to its closure. Work was resumed in the early 1940s when it was marketed under the name Barnsley Deep. The seam was worked until its exhaustion in 1986.

Work on sinking a third, 4.25 metre diameter, shaft began in April 1920, but work was not continuous. It reached the Shafton seam, which had a section of 1.4 metres, at a depth of around 229 metres in November 1923. No.3 Shaft was then treated as a separate colliery, called South Elmsall, but it relied on Frickley’s No.2 Shaft for upcast. The Shafton seam was worked in 1924, but then stood until 1942, when development resumed. Because of its proximity to an aquifer, the seam was first mined using pillar and stall. Longwall faces soon replaced it, however. Work continued as South Elmsall until 1966 when it was closed because the Shafton seam was exhausted.

From 1967 to 1989 the mines were merged under the title Frickley-South Elmsall. In the late 1960s drifts were driven to the 1.4 metre thick Cudworth seam, 67 metres below. Like the Shafton seam, the area available for working was restricted by faulting. Headings were driven north-east and south-west from the shafts, using Dosco road-headers, and a series of fully mechanised longwall faces were worked at right-angles to them. Skip winding was installed in the summer of 1971.

In preparation for the exhaustion of the Cudworth seam, work on developing the Newhill and Meltonfield Seams began in 1991. These seams were 158 and 183 metres below the Cudworth, respectively.

Returning to Frickley, the last Barnsley seam faces, in the area northwards from the former Red House round-about on the A1, worked until 1982, when that seam was abandoned. It was replaced by faces in the Top Haigh Moor, which was some 70 metres deeper.

The colliery’s surface plant underwent a major modernisation under the “Plan for Coal”. The old washery as replaced, the steam engine on No.2 Shaft, as well as the electric winder on No.1 Shaft were both replaced, and each shaft got a new headgear. The boiler house and its chimney were both demolished.

Despite the optimism of these new developments, the colliery could not compete against the prices of imported coal and so production ended November 26th 1993, with 740 men losing their jobs.

Further reading:

- NMRS Records, Gazetteer of British Collieries

- Hill, A. The South Yorkshire Coalfield: A History and Development (Stroud: Tempus, 2002)

- Hill, A. Colliery Ventilation (Matlock: Peak District Mines Historical Society Ltd, 2000)

- Hill, A. Coal: A Chronology for Britain (NMRS, British Mining No.94, 2012)

- NUM Report to Annual Conference, 1984

Return to previous page