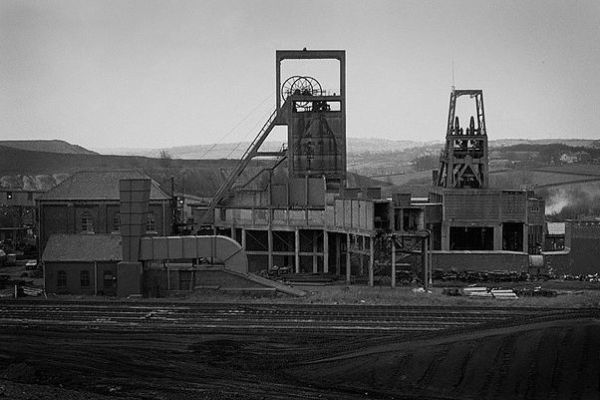

Cortonwood Colliery

Copyright © Bjorn Rantill and used with his kind permission

The site chosen for this colliery was 1.6 km south of Wombwell, but was near the M.S.&L.R’s, later G.C.R., Elsecar Branch line and the Elsecar Branch of the Dearne and Dove canal. A hamlet of some 55 houses, called the Concrete Cottages, was built nearby for the workers. It had its own school and a methodist chapel. Later, housing was added to nearby Brampton.

The Corton Wood Coal Co. began sinking No.1 Whitworth Pit, named after a board member, in October 1873. In order to prevent ingress of water from old workings in the Meltonfield seam the six metre diameter shaft was lined with tubbing to a depth of 78 metres. The Barnsley seam was reached at 192.5 metres. The 4.6 metre diameter No2, or Upcast, Shaft was fitted with a 3.66 metre diameter by 0.61 metre wide Schiele Fan in 1877.

Both shafts were deepened to the Thorncliffe seam, at 463 metres, between 1907 and 1908. This allowed the development of the 1.7 metre thick Parkgate seam at 439.5 metres. At the same time, the company remodelled its surface plant and built a new coal preparation plant to serve new coke and by-product plants. Sinking proceeded with minimal interruption of coal winding in No.1 Shaft and coal was being raised from the Parkgate seam by 1909. That coal, however, was wound at No.2 Shaft until it too was exhausted in 1941. From 1912 the new underground developments were ventilated by a 4.7 metre diameter by 1.8 metre wide Walker fan.

In preparation for the Barnsley reserves being worked out, which came in 1921, the Swallow Wood seam, at a depth of 246.4 metres, was developed from 1916. At the shaft the latter seam, which was also called the Haigh Moor, had 1.27 metres of coal, split by a 0.2 metre dirt band. It was idle between 1935 and 1943, and restarted in 1935 and worked until exhausted in 1974. Around 1935 the 0.61 metre thick High Hazel seam was also worked until 1937. It was 78 metres above the Barnsley workings.

Preparations for working the 1.1 metre thick Silkstone seam, at 525.6 metres, began in 1925 when No.1 Whitworth Pit was deepened to 554.6 metres, and skip winding was installed. On the surface, the shafts were fitted with electric winders, new compressors were installed and a new coal preparation plant was built. Silkstone coal went, via a cross-measures drift, to the Parkgate level at No.2 Shaft, where it was wound to the surface.

Under the National Coal Board, with work concentrated in the Silkstone and Swallow Wood seams, further modernisation came in the early 1960s. Coal wound from both seams at No.1 Shaft was treated at a new coal preparation plant.

The exhaustion of the Swallow Wood seam in 1974 left the mine reliant on its Silkstone faces. It was a good coking coal, but a fall in demand for coke left it with unsellable stocks. The NCB’s proposed closure of Cortonwood in March 1984, with the dispersal of its workforce to Maltby, Barnburgh, Treeton and Silverwood collieries, sparked the eleven month strike. Cortonwood remained standing after the strike, but officially closed on October 25th 1985. The surface plant was demolished in 1986.

Further information:

- NMRS Records, Gazetteer of British Collieries.

- Hill, A. The South Yorkshire Coalfield: A History and Development (Stroud: Tempus, 2002).

- Hill, A. Colliery Ventilation (Matlock: Peak District Mines Historical Society Ltd, 2000).

- Hill, A. Coal: A Chronology for Britain (NMRS, British Mining No.94, 2012).

- Coal News, July 1985

- Coal News, November 1985, p.10 – Closure agreed in October.

- NUM Report to Annual Conference, 1986.