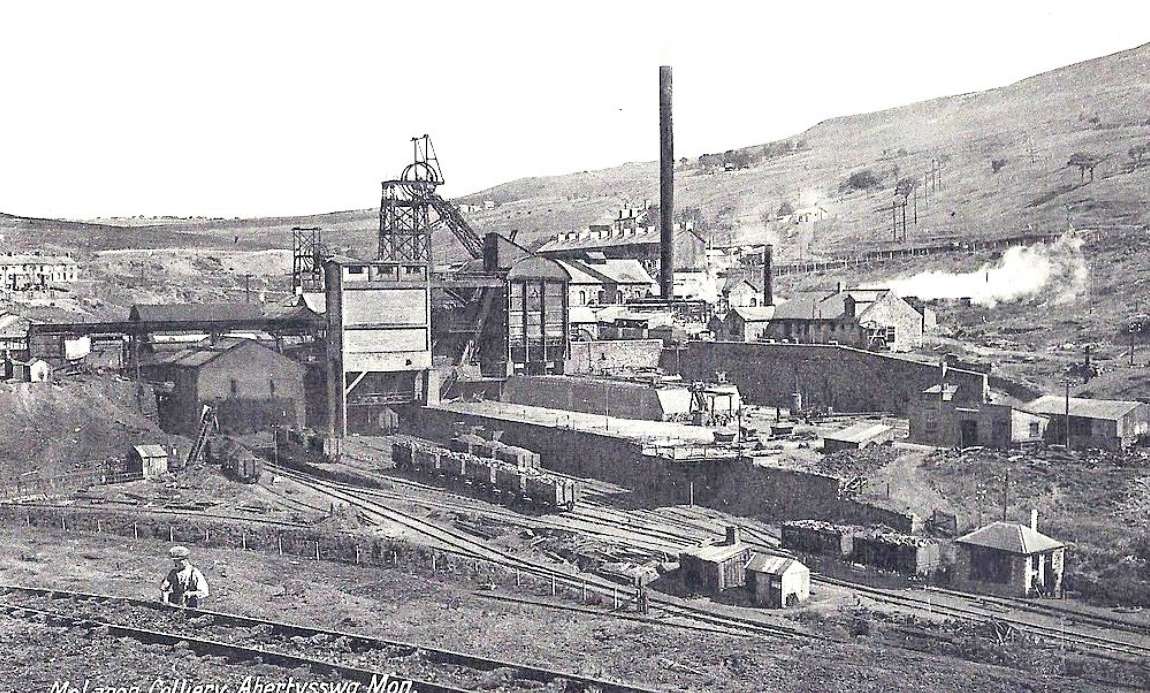

This colliery was named after Sir Charles McLaren and originally called McLaren’s Merthyr. He was a company director of the Tredegar Iron and Coal Company. This was the only pit that this company operated outside of the Sirhowy Valley, however it was a common trait for the company to name its pits after leading personalities of the company and included; Whitworth (Benjamin), Pochin (Henry Davis), Markham (Charles), Wylie (James) and McLaren.

This colliery was named after Sir Charles McLaren and originally called McLaren’s Merthyr. He was a company director of the Tredegar Iron and Coal Company. This was the only pit that this company operated outside of the Sirhowy Valley, however it was a common trait for the company to name its pits after leading personalities of the company and included; Whitworth (Benjamin), Pochin (Henry Davis), Markham (Charles), Wylie (James) and McLaren.

The Tredegar Iron Company was formed in 1800 and its early mines were used to feed the Iron Works. The first pit sunk by this company was the Dukes Pit in 1806, with sinkings continuing until the 1840s when the area of the northern outcrop of the Coalfield around Tredegar had become saturated with coal and ironstone mines. In 1873 the Tredegar Iron and Coal Company was formed to abandon iron production on a large scale and to concentrate on the by now more lucrative coal market. The old mines were now becoming exhausted and the new company started to move southwards, Whitworth and Pochin pits were sunk in the 1870s and gave the company a maximum capacity in their Tredegar mineral area, McLaren was started in 1897, and in 1906 the company obtained the mineral rights between Hollybush and Ynysddu and expanded further down the Sirhowy Valley.

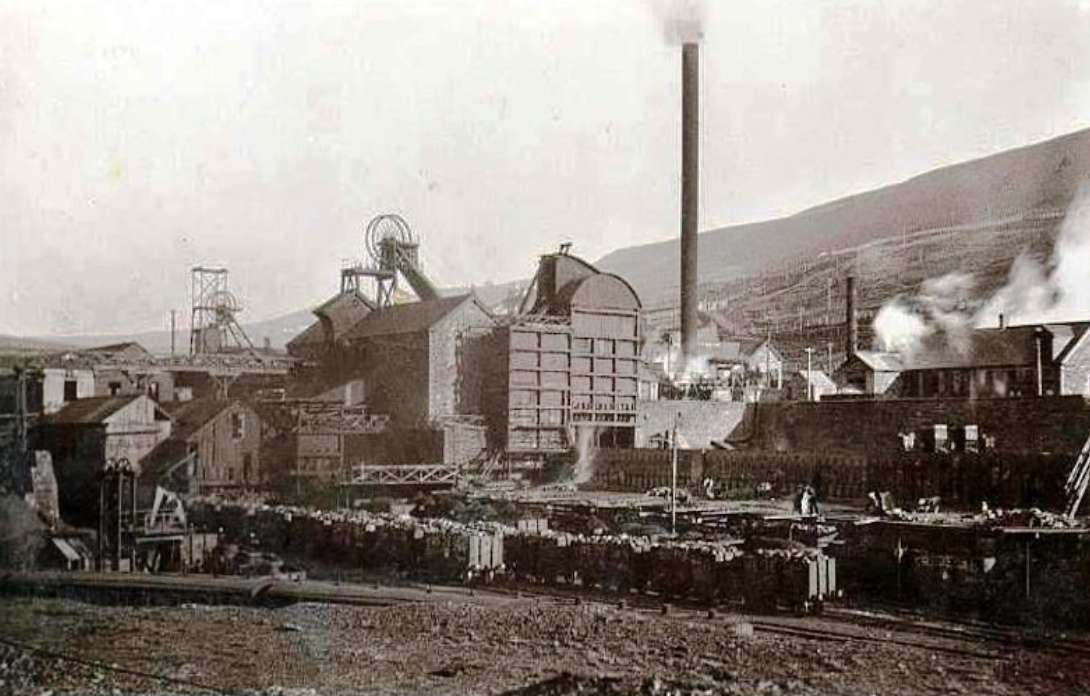

Sinking of the No.1 Pit at McLaren Colliery commenced in August 1897 and by July 1898 it was linked by underground roadway to the Bedwellty Pits, with the first coal being produced in that year. The electric power plant at the colliery was also used to light up Abertwssyg village.

It was a downcast air shaft, 16 feet in diameter and sunk 294 yards to the Rhas Las seam. It struck the 66-inch thick Big Vein at a depth of 250 yards, the Yard seam was 44 inches and 252 yards deep, the Polka seam was 45 inches thick and 292 yards deep while the Rhas Las seam varied from between 33 to 60 inches. The Pwll Laca Pit was purchased by the company in 1899 and was re-named McLaren No.2 Pit. Pwll Laca had been sunk by the Rhymney Iron Company in 1890, and following a six month long strike in 1898 it was closed down and remained so until purchased by the TIC. It was used as an upcast shaft for the No.1 Pit, and was oval in shape measuring 12 feet by 16 feet and 154 yards deep to the Yard seam. It was located 2,600 yards north of the No.1 and retained its coal production until 1913.

Initially, the Rhas Las and Polka seams were worked towards the west from the No.1 Pit, with the Polka being mined first and then the close-lying Rhas Las workings following behind and using the same roadways. The Yard and Big Vein seams were worked to the east from the No.2 Pit. The colliery was worked on a day shift for coaling, and nightshift for repairs basis. The McLaren No.3 Pit was started in 1906 and completed to a depth of 344.8 metres in June 1907.

The No.2 Rhondda seam was struck at a depth of 24.8 metres, the Four-Feet seam at a depth of 224.8 metres, the Nine-Feet seam at a depth of 262.8 metres, and the Five-Feet/Gellideg seam at a depth of 333.3 metres. This colliery was on the Admiralty’s list to supply the Royal Navy. In 1902 the manager was J. Evans, in 1908 it was still J. Evans. In 1913 McLaren Colliery employed 1,833 men and was still managed by J. Evans. Mr. Evans was still the manager in 1916 but by 1919/27 D. Kendrick was the manager. In 1915 the Business Statistics Company in their book; ‘South Wales Coal & Iron Companies’ described the Tredegar Iron & Coal Company as:

“registered on March 26th, 1873. It possesses four collieries in the Sirhowy Valley at Tredegar, and two pits in the Rhymney Valley named McLaren Nos.1 & 3, which are on the Admiralty list. The Tredegar Co, possesses a valuable property in the Oakdale Navigation Collieries Limited, now actively working Steam and House Coal Collieries in the Sirhowy Valley near Blackwood. The Tredegar Company have also acquired the entire interest of the Markham Steam Coal Co, Ltd, in the leases of valuable mineral property of 1,400 acres of coal lying between the Tredegar and Oakdale properties.”

It continued to state that the output of coal at Tredegar was about 1,750,000 tons, at Oakdale it was about 600,000 tons and at Markham it was 300,000 tons. The collieries were valued at £898,839 and the Company at £1,016,455. Profits made between 1899 and 1914 were £1,661,698. The board of directors was; Rt. Hon. Lord Aberconway, Chairman, E.A.J. Johnson-Ferguson, Arthur Lawrence, The Hon. Henry Duncan McLaren, Sir Arthur Basil Markham and Colonel A.K. Wyllie. In 1934 its directors were, Lord Aberconway, Sir Edward Johnson-Ferguson, Evan Williams, N.J. McNeill and W.D. Woolley who was also the general manager. The secretary was H.O. Monkley. At that time the company directly controlled four collieries that employed 3,102 men who produced 990,000 tons of coal. It also had subsidiary companies to run Oakdale, Markham and Wyllie collieries.

on the 3rd of September 1902, an explosion claimed the lives of 16 miners and injured 18 others. The full report can be found here.

McLaren Colliery was badly affected by the turbulent times of the mid-1920s and early 1930s and by 1935 less than a third of the 1913 manpower peak were employed at the pit, manpower standing at; 93 men on the surface and 456 men underground. The colliery had its own coal preparation plant (washery) and coke ovens. The manager at that time was T.R. Tallis. In 1938 the manager was K.D. Woolley and in 1945 it was G.H. Golding. At that time it employed 573 men working underground in the Meadow Vein, Big Vein, Upper and Lower Rhas Las and the Old Coal seams and 162 men working at the surface of the mine.

McLaren Colliery was badly affected by the turbulent times of the mid-1920s and early 1930s and by 1935 less than a third of the 1913 manpower peak were employed at the pit, manpower standing at; 93 men on the surface and 456 men underground. The colliery had its own coal preparation plant (washery) and coke ovens. The manager at that time was T.R. Tallis. In 1938 the manager was K.D. Woolley and in 1945 it was G.H. Golding. At that time it employed 573 men working underground in the Meadow Vein, Big Vein, Upper and Lower Rhas Las and the Old Coal seams and 162 men working at the surface of the mine.

A canteen was constructed in 1944 out of funds from the Miners’ Welfare Committee.

On Nationalisation in 1947 this colliery was placed in the National Coal Board’s, South Western Division’s, No.6 (Monmouthshire) Area, and at that time employed 157 men on the surface and 580 men underground working the Upper Rhas Las (Upper-Nine-Feet), Old Coal (Five-Feet/Gellideg), and Three quarter (Six-Feet) seams. The manager was R.W. Tolfree, In 1949 this name was spelled as Tollfree.

By 1954 the colliery had been reshuffled into the NCB’s No.5 (Rhymney) Area. Group No.1, and at that time employed 130 men on the surface and 600 men underground working the Red Vein, Elled, and Lower Four-Feet seams. The manager was R. Elliot. In 1955 out of a total manpower of 715 men employed at this colliery 386 of them worked at the coalfaces, the coalface figure dropped slightly to 381 men in 1956 and to 378 men at the coalfaces in 1957.

During the National Coal Board’s re-organisation fever of the 1950s, McLaren Colliery was linked by an underground roadway to Ogilvie Colliery in 1958 and closed on the 18th of July, and its coal production was diverted via Ogilvie’s shafts. Ogilvie Colliery was closed in 1968. The pit-top buildings at McLaren Colliery were demolished in 1974 and the site was landscaped in the mid-1980s.

Generally, the coals from this colliery were classed as type 204 Coking Steam Coal, medium to strong caking, and were used for steam raising in boilers for ships, locomotives, power stations etc. or for coking blends.

The ash content was between 5% to 9%, while the low sulphur content was between 0.6% to 1.5%.

Some of the fatalities:

- 17/11/1899, Josiah Williams aged 17 years, collier’s boy, fall of the roof.

- 27/5/1902, James Davies a rider was run over and killed by trams.

- 26/9/1902, John Evans aged 48 years died under a roof fall.

- 26/9/1902, David Beddoes aged 36 years died under a roof fall.

- 3/11/1902, William Taylor aged 60 years was crushed by trams.

- 8/1/1910, David Davies aged 39 years, collier, fall of roof.

- 1/3/1910, James James aged 44 years, collier, fall of roof.

- 13/5/1910, Ernest Houston aged 36 years, labourer, fall of the roof.

- 19/6/1911, Amos Leyland aged 21 years, collier, fall of the roof.

- 3/1/1913, William Jones aged 21 years, collier, fall of the roof

- 1/6/1913, W.H. Shopland aged 41 years, collier, fall of the roof.

- 24/6/1913, Arthur Lloyd aged 20 years, labourer, shaft accident.

- 28/6/1913, Abraham Williams aged 15 years, clipper, run over by trams.

- 7/2/1914, William Thomas aged 37 years, collier, fall of the roof.

- 17/4/1914, George Benbow aged 20 years, collier, fall of the roof.

- 30/4/1914, John Ballinger aged 16 years, collier’s boy, fall of the roof.

- 16/10/1914, John Jarman aged 49 years, hitcher, shaft incident.

- 2/11/1914, Albert Jones aged 20 years, collier, fall of the roof

- 17/12/1914, Thomas Handcocks aged 15 years, collier’s boy, fall of the roof.

- 28/12/1914, John Yandle aged 64 years, coal cleaner, run over by wagons.

- 16/2/1919, David Jones aged 24 years, haulier, run over by trams.

- 24/10/1927, Thomas Lance aged 37 years, collier, fall of the roof.

- 23/7/1929, Neil Coughlan aged 57 years, haulier, fall of the roof

Some Statistics:

- 1899: Manpower: 639.

- 1900: Manpower: 786.

- 1901: Manpower: 1,042.

- 1902: Manpower: 882.

- 1905: Manpower: 1,566.

- 1907: Manpower: 1,239.

- 1908: Manpower: 1,780.

- 1909: Manpower: 1,780.

- 1910: Manpower: 1,832.

- 1911: Manpower: 1,834.

- 1912: Manpower: 1,668.

- 1913: Manpower: 1,833.

- 1915: Manpower: 1,630.

- 1916: Manpower: 1,323.

- 1919: Manpower: 1,183.

- 1920: Manpower: 1,540.

- 1923: Manpower: 1,560.

- 1924: Manpower: 1,722.

- 1925: Manpower: 1,658.

- 1926: Manpower: 1,853.

- 1927: Manpower: 1,667.

- 1928: Manpower: 1,313.

- 1929: Manpower: 1,301.

- 1930: Manpower: 1,455.

- 1931: Manpower: 1,417.

- 1932: Manpower: 1,450.

- 1933: Manpower: 1,050.

- 1934: Manpower: 750.

- 1935: Manpower: 549.

- 1937: Manpower: 772.

- 1938: Manpower: 718.

- 1940: Manpower: 710.

- 1945: Manpower: 738.

- 1947: Manpower: 737.949: Manpower: 734. Output: 167,000 tons.

- 1950: Manpower: 710.

- 1953: Manpower: 619. Output: 198,000 tons.

- 1954: Manpower: 730. Output: 170,000 tons.

- 1955: Manpower: 715. Output: 160,694 tons.

- 1956: Manpower: 734. Output: 143,361 tons.

- 1957: Manpower: 729. Output: 145,185 tons.

Information supplied by Ray Lawrence and used here with his permission.

Return to previous page