New Tredegar, Rhymney Valley (national grid reference 14710274)

This colliery was sunk approximately one mile to the south of New Tredegar Colliery to exploit mineral rights negotiated from Lord Tredegar in 1882.

This colliery was sunk approximately one mile to the south of New Tredegar Colliery to exploit mineral rights negotiated from Lord Tredegar in 1882.

The Western Mail newspaper of the 19th of March 1884 reported:

That a new era is about dawning upon the locality (New Tredegar) must be self-evident to whoever visits it. The Company (Powell Duffryn) with characteristic enterprise, have long since acquired, in addition to their former taking, an immense tract of land, beneath which are the well-known valuable steam coal seams…a new pit, known as the Elliot Pit, is being sunk to more expeditiously work the coal. This new pit, will be about a mile below the existing colliery (Old Pits) which is also under great alteration in the conversion of the upcast shaft into one for winding coal…when completed instead of 700 men, being employed by the Company in the valley, the number will be more than double that…whilst the new shafts are being sunk…workings are being opened out from the existing New Tredegar Colliery, so that when the shaft is sunk to the coal, which will be by the end of the summer, headings will have been driven beneath it, and a connection made between the new and the old shafts. Working places will then be ready, and instead of the delay of opening them up, as is generally the case with a new colliery, they will be ready, and hundreds of colliers will at once find employment. Beyond the original taking, the company, as already stated, have acquired some two thousand acres, proved to contain the richest steam coal, and it is conjectured that soon after a fair start is made the output will be something like 2,000 tons a day.

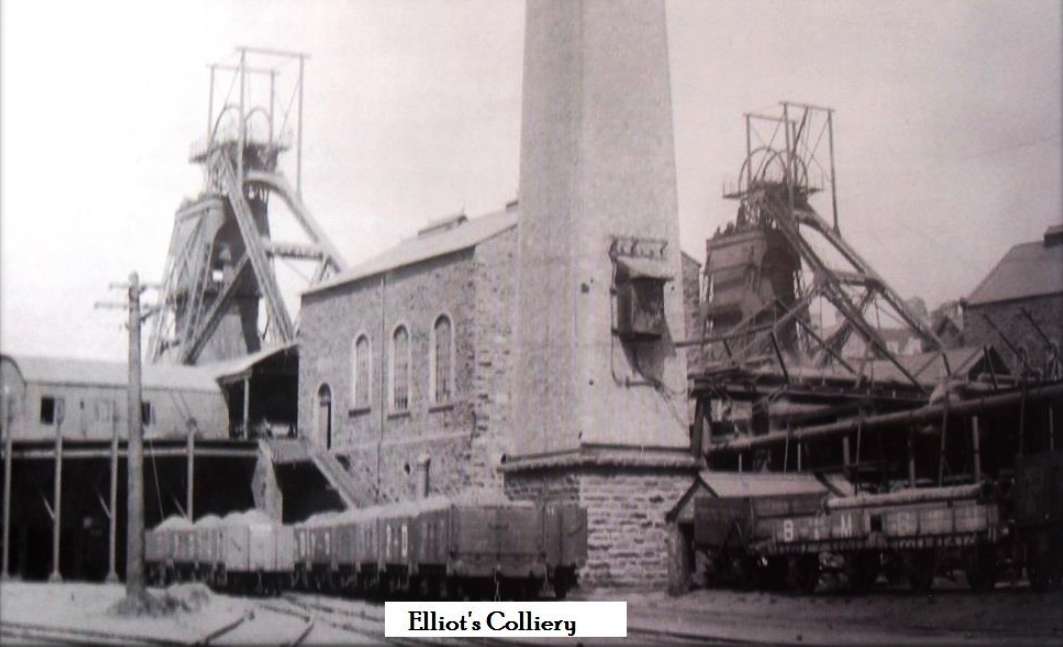

Elliot Colliery was the first of Powell Duffryn’s ‘super pits’ to be sunk in the Rhymney Valley, being followed by Bargoed, Britannia and Penallta. It was named after Sir George Elliot the originator and then chairman of the Powell Duffryn Steam Coal Company, two shafts were sunk to the steam coal seams of the Lower and Middle Coal Measures. The first sod was cut for the West (upcast ventilation shaft) on the 17th of January 1883, with the pit being sunk between 1883/5 and completed to the Ras Las seam at a depth of 450 yards in 1885. In that year 18,312 tons of coal were raised at this pit. It was later deepened a further 90 yards. It was 18 feet in diameter with the winding level at the Red Vein at a depth of 440 yards. The original contractors went down 70 yards and then packed it in for some reason or other with the company completing the task. As the newspaper article indicated the workings were opened up from the New Tredegar (Old Pits) and a 1,700 yard drivage was driven to link them up. However, the plan to have only one shaft at Elliots failed and it was decided to sink another, the East, shaft, but work them as separate collieries. The East (downcast) pit was also 18 feet in diameter and completed to the Lower-Four-Feet seam at a depth of 530 yards. The first sod was cut on the 16th of November 1888 and sinking was completed by April 1890 when an underground connection was made with the West Pit. The initial idea must have been to wind the coal produced at Elliots up the old New Tredegar Colliery but this idea was reversed in March 1890 when it was agreed to convert it to a coal winding shaft and install coke ovens at the surface.

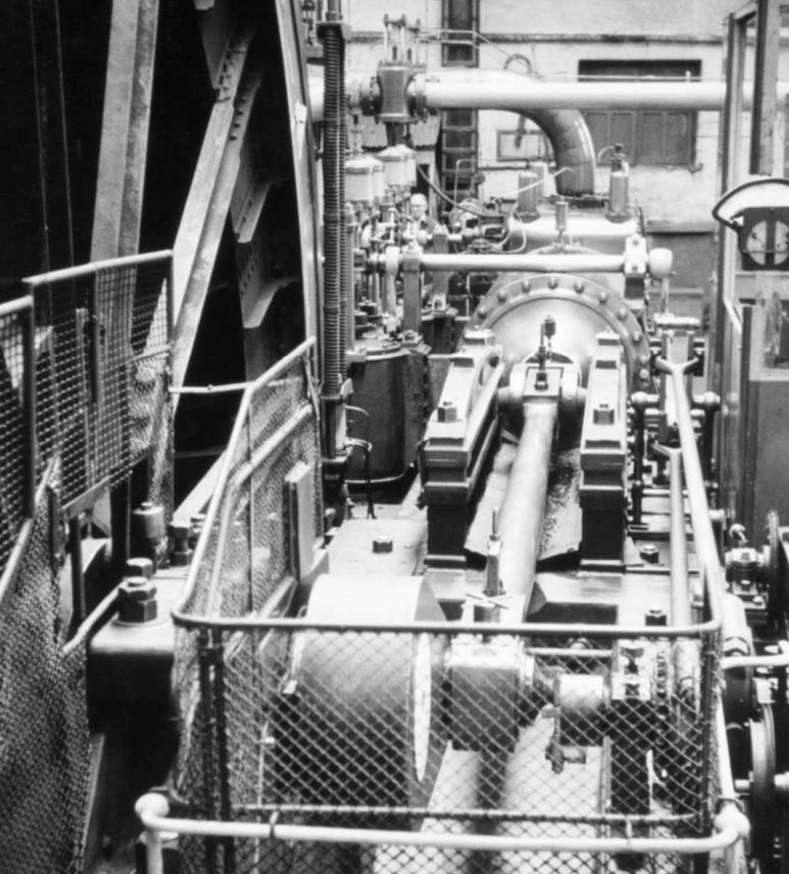

The winding engine for this pit was installed in August 1891 and was built by Messrs. Thornewill & Warham. It had two horizontal cylinders 42 inches in diameter with a six-foot stroke. The winding drum was cylindrical and 24 feet in diameter. It carried a single-deck cage with two trams per wind. Following the installation of this winder the East pit started production. The shafts were 43 yards apart, with the cost of the sinkings being £209,772. The manager was then A. Phillips.

The winding engine for this pit was installed in August 1891 and was built by Messrs. Thornewill & Warham. It had two horizontal cylinders 42 inches in diameter with a six-foot stroke. The winding drum was cylindrical and 24 feet in diameter. It carried a single-deck cage with two trams per wind. Following the installation of this winder the East pit started production. The shafts were 43 yards apart, with the cost of the sinkings being £209,772. The manager was then A. Phillips.

Ventilation of the mine was by a Waddle fan, installed in 1885, it was 45 feet in diameter producing up to 190,000 cubic feet of air per minute. The washery was constructed in 1893 along with 50 coke ovens which were later expanded to 180 ovens. They were closed in 1907 and the Bargoed coke ovens were used.

On the First of October 1885, an explosion in the shaft killed David Lewis Perkins aged 15 and Thomas Cooke aged 16 years.

The Colliery Guardian of the 10th of May 1889 reported:

The new sinking operations at Elliot Town and at Gilfach, Bargoed have imparted a most pleasing impetus to trade generally in the Rhymney and Bargoed Valleys, no less than 200 new dwelling houses being about to be immediately erected.

In February 1889 possibly the first industrial dispute at the colliery arose over the men not being paid for the “increased labour” brought about by clod falling on the coal, and also for ripping in the top stall roads. The men claimed that they had tried to settle the dispute through normal channels but had been ignored, and now they gave notice that if the matter wasn’t settled by the 1st of March they would withdraw their labour.

Water broke into the workings of the East Pit on the 6th of November 1891 reached the pit bottom and started to rise in the shafts, affecting both pits. Pumps were brought in to clear the workings but it wasn’t until the 18th of December that work re-started.

On December 1st 1890 at around midnight, William Evans, a labourer, of Railway Terrace, Tirphil, died after being run over by full coal trams that morning. The Western Mail reported in plain terms on another fatal accident in the newspaper of Saturday 5th of March 1892:

Between four and five p.m. on Friday, an alarming accident occurred at the Elliot Colliery, New Tredegar, when three men, viz. George Davies, 54, overman, Elliot Town; Thomas Powell, 26, North-terrace, New Tredegar; and Richard Roberts, aged 36, Bargoed; descended a small shaft, 86 yards in depth, sunk as a trial pit for the discovery of coal, and for access to the East and West Pits, prior to the completion of the former. Completing their work they ascended the shaft to within a very short distance to the landing, when one of the bolts that connects the top part of the cage snapped, precipitating the cage with its occupants to the bottom of the shaft. The news of the catastrophe spread like wildfire throughout the locality and immediately drew hundreds of people around the pit’s mouth. Efforts were promptly organised the bringing of the bodies to the bank, and as these reached the surface there were widespread manifestations of sorrow.

In April 1895 Powell Duffryn decided to give notice to all the workmen at Elliot’s Colliery to terminate contracts so that they could deepen the shafts. 800 men were thrown out of work. In 1896/1900 the manager was N. Phillips and the pit was working the Rhas Las seam. Initially, nine haulages were used underground with six of them being 150 hp, 2 x 50 hp, and one was 100 hp. As well as the electric haulages there were 21 compressed air smaller haulages nearer the coalfaces.

There was a serious outbreak of ‘Pink Eye’ amongst the horses at Elliot’s in October 1900 which meant that many of them had to be brought to the surface for recuperation. In April 1907 Thomas Evans, a collier, had beaten a horse around the head so badly that its head was swollen and both eyes shut. Magistrates fined him £2 with £3 costs or one month in prison.

In May 1907 the West Pit recorded a pit record of winding 2,245 tons of coal in a single day.

Sir George Elliot was born in Durham in 1817 he started his career as a pit boy in that coalfield and worked his way up through the ranks until he was rich enough to speculate in the South Wales Coalfield. In partnership with Thomas Forster and William Armstrong he purchased Thomas Powell’s pits and in 1864 became practical director of the new Powell Duffryn Company. He retired in 1877, but returned as Managing director in 1880, was chairman in 1886 and held this position until his final retirement in 1889 when he was replaced by Lord Brassey. Sir George Elliot died in 1893.

This company was a member of the Monmouthshire and South Wales Coal Owners Association. In 1884 the manager was D. Evans, in 1909/11 it was F. Wilcox.

To highlight the dangers of mining I have picked the average year of 1905 at this pit and list those that died:

- 11th February, Thomas Jones aged 45 years died under a roof fall.

- 7th March Patrick Hearne aged 31 years died under a roof fall.

- 27th of June, Thomas Batten aged 48 years run over by trams and killed.

- 27th of June, David J Griffiths aged 19 years run over and killed by trams.

- 1st August George Lewis aged 19 years died under a roof fall.

- 16th of August George Price aged 25 years died under a roof fall.

- 3rd October David J Hammond aged 25 years died under a roof fall.

- 5th of October George Nuttall aged 18 years was killed when run over by trams.

- 8th of November James Griffiths aged 60 years killed when run over by trams.

On the 24th of October 1910 one of the cages in the shaft crashed from the surface to pit bottom seriously damaging the shaft, they were winding coal at the time so no men were hurt, but 1,000 were laid off until repairs could be made. Not so lucky for five men who died under one fall of roof on Thursday the 30th of December 1915.

Both Elliot Colliery and Powell Duffryn grew from strength to strength and by 1913 this pit employed a total of 2,757 men. The manager at that time was J.A. Price. He was still the manager in 1923. In 1913 PD employed over 13,000 men and had a total coal production of almost four million tons.

In that year the company advertised:

The Powell Duffryn Steam Coal Company Limited Head Office:- Cardiff. Proprietors and Shippers of the ‘Powell Duffryn’ Steam Coal – Annual Output About 4,000,000 tons. On the British Admiralty List Also Supplied To:- The Chief Foreign Navies; and great Steamship Lines of the United Kingdom and Foreign Countries; and the Principal Railways in the United Kingdom and its possessions beyond the Seas, and to those of Foreign Countries. Largely used by the Consumers of Smokeless Steam Coal in London. Proprietors and Shippers of Washed Paris Nuts Washed Steam Nuts, Beans, Peas, Grains & Duff. Foundry & Furnace Coke of the highest quality. Sulphate of Ammonia, Sulphuric Acid, Tar, Pitch, Creosote, Anthracene Oil, Etc Manufacturers of Bricks, Chimney Pots, Sanitary Pipes, Etc Shipping Ports: Cardiff, Newport, Swansea and Southampton. Coal sent by rail direct from Collieries and tipped into barges from the Company Belvedere Wharf, Southampton, by special anti-breakage appliances for supply to Warships, Mail Steamships and Yachts British Agencies: Liverpool, London, Glasgow and Wolverhampton (for coke). Foreign Agencies: Rouen, Bordeaux, Havre and Nantes. Registered Offices:- 101, Leadenhall Street, London.

On the 21st of July 1920, the Western Mailed posted:

HEROISM A MONMOUTHSHIRE MINE. At Buckingham Palace yesterday. Duke of York, on behalf of the King, bestowed the ‘Edward Medal silver on Mr Jeffrey Fletcher for gallantry in mine West Elliot Colliery, Monmouthshire. A man had been buried fall of earth, and for about five hours Mr Fletcher persisted in rescue work in circumstances of great personal danger and in spite ‘of a second burial of the man in question, to save his life.

On the 25th of August 1926 during the general strike, thirty-three men returned to work at this pit and were ambushed on the way home by booing women who waved white shirts and whitewash.

In 1938 colliery manager was M. Davies and in 1943/5 it was T. Farrell. At that time the East Pit employed 521 men working underground in the Seven-Feet and Lower Four-Feet seam while the West Pit employed 483 men working in the Rhas Las, Red and Upper Four-Feet seams. 266 men were working at the surface of the mine.

On Nationalisation in 1947, Elliot Colliery was placed in the National Coal Board’s, South Western Division’s, No.5 (Rhymney) Area, Group No.1, and at that time employed 304 men on the surface, and 1,104 men underground working the Seven-Feet, Lower-Four-Feet, Upper-Four-Feet and Rhas Las seams. The manager was G. Tomkins. He was still there in 1949. In November 1953 the NCB decided to try and eliminate the delays to getting the coal to the pit bottom by installing a new trunk conveyor system at a cost of £145,000. Manpower increased slightly to 321 men on the surface and 1,375 men underground in 1954 when the pit worked the Yard, Seven-Feet, Lower and Upper Four-Feet seams. The manager was now R.L. Burnett. At that time this colliery had its own coal preparation plant (washery), a coal selling depot, and the site of a mines rescue station.

In 1955 a new pit bottom was constructed at the West Pit. A conveyor belt from the Upper-Four-Feet and Yard seams would bring the coal to the top of a newly made staple pit close to the pit bottom from where the coal was loaded into trams on a vibrating plate. They would then gravitate to the pit bottom. In 1955 out of a total manpower of 1,704 men, 904 of them worked at the coalfaces, the coalface figure dropped to 845 men in 1956, 813 men in 1957, and 780 men in 1958. In 1961 out of a total manpower of 1,227 men, 502 of them worked at the coalfaces. In 1961 this colliery was still in the No.5 Rhymney Area, along with Ogilvie and Groesfaen collieries. The Group had a total manpower of 3,643 men, and a total coal production for that year of 814,099 tons. The Group Manager was J.H. Jenkins while the Area Manager was G. Tomkins. The Colliery Guardian of the 17th of May 1962 reported that the NCB denied that they were thinking of closing this colliery, the West Pit was then closed as a production unit on the 1st of October 1962 on the grounds that it was no longer economic to work. The men were transferred to Ogilvie and Groesfaen. Elliot Colliery, one of the largest and most productive collieries in the South Wales Coalfield failed to survive the closure programme of the l960s and closed on April 29th 1967.

This colliery’s coal was generally classed as type 204 Coking Steam Coal, which was medium to strong caking, and used for steam raising and coking blends. The ash content was around 5%, while the sulphur content was between 0.6% to 1.5%.

The winding engine house and a steam winding engine have been preserved by Caerphilly County Borough Council and can be visited on-site at SO 1474 0272.

Some of the other early fatalities at this colliery:

- 7/6/1884 Gwyliam Williams aged 21 years and a sinker, killed in the shaft,

- 30/8/1884 William Morgan aged 45 years, engineman, killed in the shaft.

- 11/8/1885 Phillip Evans aged 29 years, hitcher, killed by cage

- 26/4/1890 Phillip James aged 26 years, collier, killed by a fall of roof

- 14/8/1890 Daniel Wilkins aged 22 years, collier, killed by fall of roof

- 14/8/1890 William Evans aged 47 years a dayman, killed by trams

- 31/12/1890 Roger Griffiths aged 36 years a master haulier, killed by trams

- 4/3/1892 Richard Roberts aged 36 years, roadman, killed in a staple shaft

- 4/3/1892 Thomas Powell aged 26 years, rider, killed in a staple shaft

- 4/3/1892 George Davies aged 54 years, overman, killed in a staple shaft

- 11/3/1893 John Williams aged 48 years, stoneman, killed by a fall of roof

- 14/1/1894 Charles England aged 34 years an engineman, killed by machinery

- 10/3/1897 Isaac Price,34 years, haulier, killed by trams in the East Pit

- 29/1/1898 Robert Evans 29 years, collier, killed by a fall of roof in the West Pit

- 2/3/1898 Joseph Thomas aged 49 years, haulier, killed by trams in the West Pit

- 21/6/1911 Robert Pugh aged 44 years, timberman, killed by trams in the West Pit

- 23/2/1912 Godfrey Pugh aged 20, labourer, killed by a fall of roof in the East Pit

- 16/4/1912 Rees Shore aged 51 years, sheaver, killed by trams in the East Pit

- 5/5/1914 Abathian Davies aged 15, collier’s boy, killed by fall of roof in the West Pit

- 7/11/1914 William Upton aged 39 years a rider killed by trams in the West Pit

- 18/12/1928 William Slater aged 53 years a hitcher, fell down in East Pit

- 28/6/1929 Thomas Hughes aged 27 years a rider killed by trams in the West Pit

- 13/8/1929 Alfred Angel aged 67 years a stower killed by trams in the East Pit

Some Statistics:

- 1889: Output: 154,859 tons.

- 1894: Output: 287,000 tons.

- 1896: Manpower: 1,687.

- 1899: Manpower: 1,376.

- 1900: Manpower: 1,187.

- 1902: Manpower: 1,973.

- 1903: Manpower: 2,219.

- 1905: Manpower: 2,334.

- 1907: Manpower: 2,383.

- 1908: Manpower: 2,571.

- 1909: Manpower: 2,671.

- 1910: Manpower: 2,673.

- 1911: Manpower: 2,464.

- 1912: Manpower: 2,811.

- 1913: Manpower: 2,757.

- 1915: Manpower: 2,850.

- 1918: Manpower: 2,171.

- 1923: Manpower: 2,442.

- 1924: Manpower: 2,900.

- 1925: Manpower: 2,500.

- 1926: Manpower: 2,200.

- 1927: Manpower: 2,017.

- 1928: Manpower: 2,078.

- 1929: Manpower: 2,069.

- 1930: Manpower: East Pit: 1,013. West Pit: 1,064.

- 1933: Manpower: 1,478.

- 1934: Manpower: 1,384.

- 1935: Manpower: 1,490. Output: 450,000 tons.

- 1937: Manpower: 1,732.

- 1938: Manpower: East Pit: 817. West Pit: 952.

- 1940: Manpower: 1,367.

- 1941: Manpower: 1,442.

- 1942: Manpower: 1,342.

- 1944: Manpower: 1,334.

- 1945: Manpower: East Pit: 521. West Pit: 483. Surface: 266.

- 1947: Manpower: 1,408.

- 1948: Manpower: 1,478. Output: 528,500 tons.

- 1949: Manpower: 1,645. Output: 528,500 tons.

- 1950: Manpower: 1,663.

- 1953: Manpower: 1,676. Output: 742,000 tons.

- 1954: Manpower: 1,696. Output: 424,461 tons.

- 1955: Manpower: 1,705. Output: 428,014 tons.

- 1956: Manpower: 1,704. Output: 406,968 tons.

- 1957: Manpower: 1,693. Output: 405,856 tons.

- 1958: Manpower: 1,626. Output: 434,827 tons.

- 1960: Manpower: 1,307. Output: 276,306 tons.

- 1961: Manpower: 1,227. Output: 257,576 tons.

- 1962: Manpower: 1,233.

- 1967: Manpower: 1,200.

Information supplied by Ray Lawrence and used here with his permission.

Return to previous page