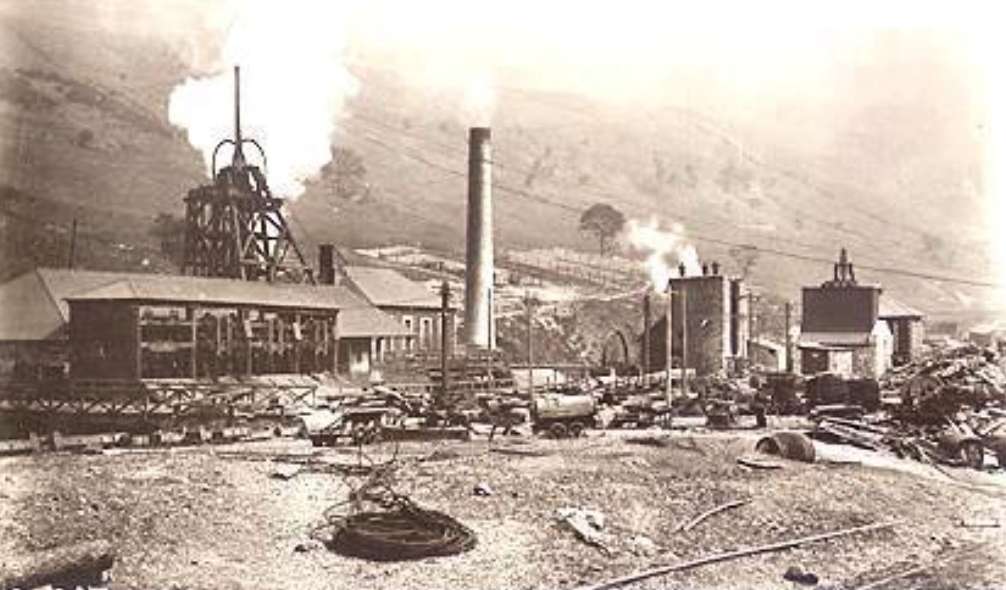

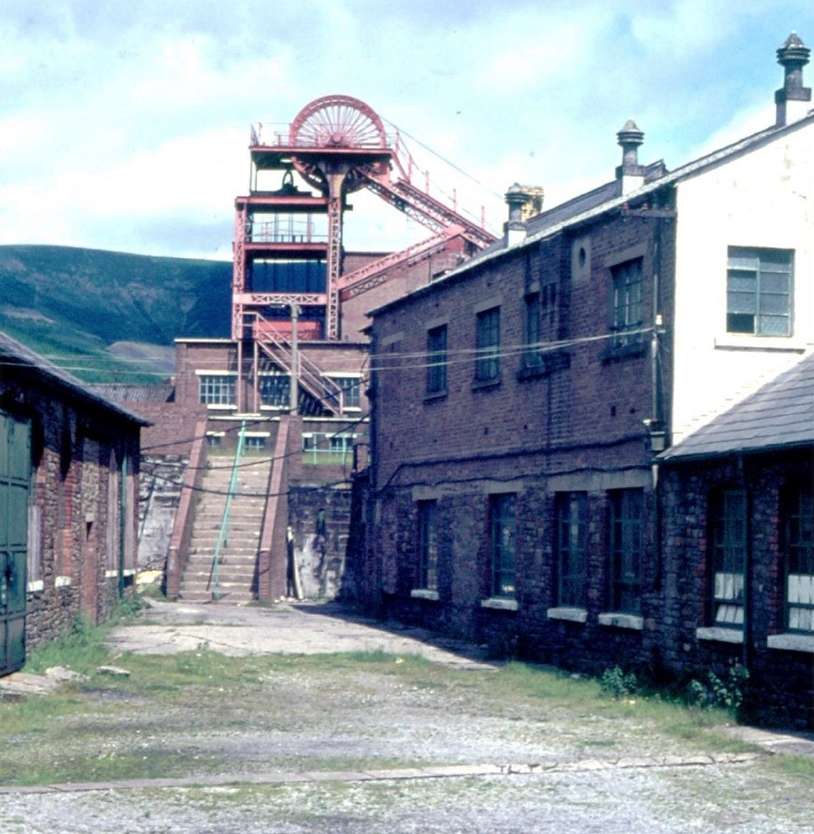

Garw Colliery

The coal board decided that due to the Garw Colliery and Ffaldau Colliery working adjacent to each other, it would be more economical if they merged. This involved an underground roadway of 500 yards in length being driven to connect the collieries and all coal winding, manriding and supplies to go down the Garw shaft while the Ffaldau would be kept open for ventilation only. On top of this, the NCB decided to embark on a boring programme to prove the vast reserves of prime coking coals that lay to the south of St. John’s, Garw/Ffalda and Wyndham/Western collieries. There were a number of proposals on how to work this coal:

- Keep St. John’s separate and merge Garw, Ffaldau and Wyndham, Western into one concern. This would mean a 3,000-yard drift that intercepted all the seams and brought the coal up to the surface in the centre of the St. John’s take and then took it by overland conveyor to Maesteg Washery.

- To raise the output of the three collieries at one central point. This would involve a 3,000-yard drift central to the Garw, Ffaldau and Wyndham, Western reserves that would take the coal to the Ogmore Valley washery.

- A strategically sited central drift would take the combined coals of the three mines to a new washery. This method seemed to have been favoured due to it providing a large elimination of manpower by cutting out coal winding at the three mines plus getting rid of three washeries. But, alas, events overtook those grand plans.

It was then estimated that the combine had 7.5 million tonnes of coal reserves.

Garw Colliery was merged with Ffaldau Colliery in 1975 at a cost of £86,000, a 500-yard underground roadway linked the two pits with Ffaldau’s output of coal brought up the Garw’s shafts. Manwinding capacity per wind was 28 men with coal winding being 3.2 tonnes per wind. It was estimated then that the new combine had 7.5 million tonnes of coal as reserves. The expected annual output was 380,000 tons of coal, with an output per man shift of just over two tonnes.

The mineral take was bounded by the Glyncorrwg geological fault to the east and the Blaengarw fault to the west. The winding engines were equipped with 1,400 hp motors capable of winding 28 men or 3.2 tonnes of coal at a time.

By 1979 the G68 coalface in the Garw section of the combine was unusually coaling on nights and days.

Ffaldau Colliery

On the 17th of August 1979, thirteen men on the M1 coalface had to don their rescue equipment and leave their place of work when smoke came down the ‘face. It was found that a conveyor belt had stalled causing the belting material to melt and create smoke. It was also in 1979 that tragically a six-year-old boy was drowned in the pit water feeder. Around that time there were eleven miles of roadway in use with around four miles of conveyors. The average output per man shift at the coalface was 4.4 tonnes, and overall for the colliery it was 1.5 tonnes. The average saleable output of coal was 5,300 tonnes per week.

In 1981 the combine worked the Lower-Nine-Feet seam at a section of 1.2 metres, the Bute seam at a section of 1.3 metres and the Gellideg seam at a section of 1.5 metres. Coalface length varied from between 115 metres and 220 metres, with all coalfaces having powered supports of the self-advancing types and ranging drum shearers for coal cutting. The Lower-Nine-Feet seams were prefixed by the letter M, with the M3 being stopped at a geological fault in February 1981, the M4 at that time having a life of 310 metres and advancing 1.5 metres per day on double shift coaling. The M5 & M6 were to follow these coalfaces. The Bute seam coalfaces were prefixed by the letter B, with the B1 having a life of 900 metres and advancing 1.6 metres per day and double shift working. The B10 in seam miner was to produce a constant 75 tonnes a day. The Gellideg seam coalfaces were prefixed with a letter G, the G73 had just been stopped, and the G72 had a life of 550 metres with a daily advance of 2 metres on two coaling shifts.

Daily output was around 1,250 tonnes, with coalface output per manshift being 5.37 tonnes, and overall output per manshift being 1.73 tonnes. The saleable coal yield was 60%. Manpower deployment was; coalface 230, development 177, elsewhere below ground 185, surface 736. The manager Mr. J. Smith was concerned about manning levels at this pit and wanted fifty to sixty more men to fulfil the development programme. In 1983 the colliery was losing £38.50 for every tonne of coal that it produced, the fourth worst performance in the South Wales Coalfield. Manpower at that time was 689 men.

In March 1983, the NUM held a national ballot on whether to take strike action over pit closures, 68% of the South Wales membership voted for strike action, but overall in the UK’s pits, only 39% voted that way and a national strike was abandoned. This was the vote that was later to cause a lot of confusion and bitterness at the start of the big strike.

Following the return to work after the 1984/85 miner’s strike, by April of that year the colliery had attained a reasonable 89% of expected output levels, but the B1 coalface hit adverse geological conditions and closed leaving the M7 coalface to produce 7,500 tonnes per week to keep the pit open, this wasn’t attainable and it closed on the 13th of December 1985 on the grounds that it was uneconomic.

The closure was hotly disputed by the local M.P. with his scathing attack recorded in Hansard.

Some statistics:

- 1976: Manpower: 784.

- 1978: Manpower: 902. Output: 240,000 tons.

- 1979: Manpower: 825. Output: 225,000 tons.

- 1980: Manpower: 844. Output: 224,759 tons.

- 1981: Manpower: 736.

- 1982: Manpower: 730. Output: 139,000 tons.

- 1985: Manpower: 727.

Information supplied by Ray Lawrence and used here with his permission.

Return to previous page