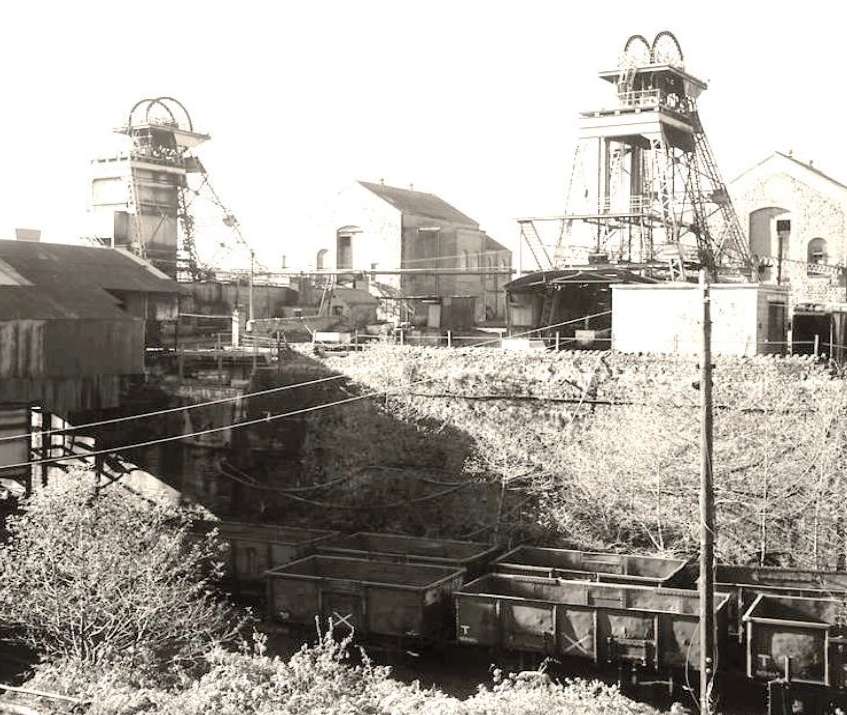

Maesteg, Llynfi Valley (87569166)

Industrialisation of this area on a small scale started with the opening of the Llynfi and Porthcawl Tramroad in 1827, this enabled the construction of the Maesteg Ironworks which struggled on under various forms until closure in 1880. Well before the closure of these works coal mining had started to take precedence in the area, helped mainly by the construction of the Great Western Railway up the Valley from 1860. Larger and deeper mines were sunk:

Industrialisation of this area on a small scale started with the opening of the Llynfi and Porthcawl Tramroad in 1827, this enabled the construction of the Maesteg Ironworks which struggled on under various forms until closure in 1880. Well before the closure of these works coal mining had started to take precedence in the area, helped mainly by the construction of the Great Western Railway up the Valley from 1860. Larger and deeper mines were sunk:

- Maesteg Deep,

- Garth and Oakwood in the 1860s,

- Coegnant Colliery in 1882,

- Caerau Colliery in 1893

- St. John’s Colliery in 1910.

St. John’s Colliery was to work the southern part of a mineral take that stretched from Maesteg in the south to Cymmer in the north. The owners of St. John’s, North’s Navigation Collieries (1899) Limited which was to work the southern part of a mineral take that stretched from Maesteg in the south to Cymmer in the north.

The owners of St. John’s, North’s Navigation Collieries (1899) Limited was formed from the ashes of the old Llynvi, Tondu and Ogmore Coal and Iron Company by Colonel J.T. North and partners in 1899 with a capital of £450,000. Under the guidance of North and the mining engineer T. Forster Brown, the company acquired further mineral rights in the Llynfi and Ogmore Valleys and soon controlled an area of 10,000 acres. In 1916 this Company came under the control of Lord Rhondda, although it retained its name, and by 1922 almost £3,000,000 had been paid out in dividends to shareholders. In 1934 North’s Navigation Collieries (1899) Limited was based at Aberdare House, Mount Stuart Square, Cardiff with the directors being; Sir D.R. Llewellyn, Viscountess Rhondda, J. Wentworth Smith, W.P. Miles, C.P. Hailey, H.H. Merrett, W.E. Davies, F. Llewellyn Jacob and W.M. Llewellyn. The company secretary and commercial manager was W.E. Davies. This subsidiary company controlled five collieries that produced one million tons of coal and employed 4,104 miners. Along with Lord Rhondda’s other mining interests, North’s Navigation was merged into Welsh Association Collieries Limited in 1929, which in turn was merged into Powell Duffryn Associated Collieries Limited in 1935 then held the colliery until Nationalisation in 1947.

St. John’s Colliery was located on the site of the old Cwmdu Colliery which had worked the upper coal seams, particularly the Victoria seam. It was sunk in 1910 to a depth of 385 yards to the steam coal seams of the Middle and Lower Coal Measures. Its mineral take was bounded by the Lletty Brongu geological fault to the west, the Fforchlas fault to the east and the Molau Gilau fault to the south. They encountered adverse geological conditions when trying to open up the colliery. It mainly worked the Gellideg seam at a thickness of up to 66 inches. The Five-Feet seam was worked and had a thickness of 78 inches. The Yard seam was worked as the No.8 seam at this colliery and had a thickness of around 36 inches. The Bute seam was extensively worked and called the Lower New seam. It varied to up to 53 inches in thickness. The Lower-Nine-Feet seam was extensively worked as the Upper New seam. It had a thickness of 60 inches. The Upper-Nine-Feet seam was worked as Harvey’s seam and had a thickness of around 42 inches. The Lower-Six-Feet seam was extensively worked and had a thickness of up to 84 inches. There were little workings in the Upper-Six-Feet seam which varied in thickness from 26 inches to 40 inches. The Two-Feet-Nine seam was worked and had a thickness of 60 inches. Following the closure of Maesteg Deep Colliery in 1930 St. John’s Colliery also worked this seam in that area. The Pentre Rider seam was called the Victoria seam at this pit and was worked at a thickness of around 39 inches.

The South Pit was 326 metres deep and the upcast ventilation shaft and sunk to exploit the Lower and Upper New seams. The North Pit was 335 metres deep and the downcast ventilation shaft was sunk to work the Seven-Feet, Six-Feet and Two-Feet-Nine seams. Both pits were 18 feet in diameter. Initially, both pits were used for coal winding and were capable of winding 1,000 tons each per eight-hour shift. Each wind could take 25 men or 2.7 tonnes of coal. The South Pit worked the Lower & Upper New seams while the North Pit worked the Seven-Feet, Six-Feet and Two-Feet-Nine seams. Originally ventilation was by a 11 feet in diameter Schiele-type fan, while in 1917 a Walker-type fan was installed that was 20 feet 6 inches in diameter and 8 feet wide.

From the manpower of 638 in 1913 when it was managed by J.R. Gibbon, and in 1916/19 by J. Jones, it grew to double that figure to 1,370 by 1922. In May 1920 the North’s Navigation Collieries (1889) Limited issued a paper called ‘Coalmining Industry Outlook’ and in it stated that there had been considerable improvement underground at St. John’s, this pit had been a source of great worry to the company, but they claimed that they had now driven through the geological disturbances and several seams of good quality and thickness were available. They believed it could now be the most successful colliery of the company.

- On the 30th of October 1924, Isaac Nash, aged 62 years, and a haulier, was run over by trams and killed.

- On the 4th of November 1924, by the death of David Evans, aged 58 years, and a fireman, who died under a fall of the roof.

- On the 14th of October 1929, Randall White, aged 17 years, and a collier, died under a fall of roof.

- On Saturday, December the 20th 1930, George Thomas a haulier, was killed, and two officials, Isaiah Waldine and Griffith Thomas, were seriously injured when they were hit by runaway trams.

In 1927 the manager was W. Morgan. In 1919 the collieries coals had various markets, with the Two-Feet-Nine seam claimed to be the “best house coal in the market”. Washed nuts were sold to electrical works and bunkers, foundry coke was sold to engineering firms, government arsenals, dockyards and munitions works. Its small coal was used by steamers. The three-month general strike of 1921 had already heralded troubled times for the Coalfield and by 1935 manpower had roughly halved to 132 men on the surface and 594 men underground. The manager was W. Morgan. Manpower had bounced back up to 1,480 men by 1940. In 1943 this mine employed 967 men working underground in the Six-Feet, Lower and Upper Five-Feet and Two-Feet-Nine seams and 175 men working at the surface of the mine. In 1943/5 the manager was R.E. Petty.

In 1927 the manager was W. Morgan. In 1919 the collieries coals had various markets, with the Two-Feet-Nine seam claimed to be the “best house coal in the market”. Washed nuts were sold to electrical works and bunkers, foundry coke was sold to engineering firms, government arsenals, dockyards and munitions works. Its small coal was used by steamers. The three-month general strike of 1921 had already heralded troubled times for the Coalfield and by 1935 manpower had roughly halved to 132 men on the surface and 594 men underground. The manager was W. Morgan. Manpower had bounced back up to 1,480 men by 1940. In 1943 this mine employed 967 men working underground in the Six-Feet, Lower and Upper Five-Feet and Two-Feet-Nine seams and 175 men working at the surface of the mine. In 1943/5 the manager was R.E. Petty.

On Nationalisation in January 1947, St. John’s Colliery was placed in the National Coal Board’s, South Western Division’s, Area No.2, Maesteg Group, and at that time employed 185 men on the surface and 976 men underground working the Six-Feet, Lower and Upper Five-Feet, Two-Feet-Nine and New seams. The manager was R.E. Petty who was still there in 1949. In the 1950s the NCB showed faith in the pit and fully electrified the winders and in 1955 erected new pit head baths and medical centre. By 1954 manpower had dropped to 177 on the surface and 909 men underground working the same seams for coking, house and steam coals with the manager now being R.A. Evans.

On Tuesday, 6th of October 1954, two men died from the effects of methane gas poisoning in the North Pit.

In 1956 the price list for the Gellideg seam was two shillings and seven pence per square yard in a thickness of 4 feet 3 inches. The National Union of Mineworkers Lodge at St. John’s, along with most other lodges in the Coalfield, attempted to tend to the needs and welfare of their members not only in work but on the social side as well, and in 1956 St. John’s started to organise Christmas Parties for the children of their members, which by 1958 catered for 700 children at a cost of £1,000.00.

In 1957 this colliery employed 89 youths the highest figure in the Maesteg Area. The other, more militant side of the Lodge can be seen during the 1972 miner’s strike when they withdrew safety cover against the advice of the National and Area Union Leadership. In 1961 this colliery was still in the No.2 Area’s, Maesteg Group, along with Caerau, Bryn and Coegnant Collieries. The total manpower for this Group was 2,720 men, while the total coal production for that year was 768,562 tons. The Group Manager was C.P. Jones and the Area Manager was W.B. Cleaver. In 1969/78 the manager was A. J. Reed and in 1979 to 1980+ it was T.M. Bond.

In the late 1970s, the pit worked an area of about six square miles in the Lower Six-Feet, Lower Nine-Feet and Gellideg seams. The coal winding rate was 2.7 tonnes per wind with a 1,000hp winding engine which could also raise/lower 25 men per wind. The average output per manshift at the coalface was 3 tonnes and overall for the colliery, it was 1.4 tonnes.

On Friday the 24th of May 1974 Prince Charles made an underground visit to the S1 District.

By 1980 this pit had around 13 miles of underground roadways in use and around five miles of conveyor belts at work which was one of the reasons for losses which were running at £37,000 per week, part of the plan was to alleviate the problem of transportation delays by driving a new one-mile roadway from the pit bottom to the current workings. In 1981 this colliery was working the Lower-Six-Feet seam at a thickness of 1.3 metres, with coalface length varying from between 90 metres to 110 metres. Coal cutting and loading were done by ranging drum shearer, and the coalface roof supports were of the self-advancing type. The Lower-Nine-Feet seam was being worked at a thickness of 1.5 metres, with coalface length varying from between 80 metres to 137 metres. Coal cutting and loading were done by ranging drum shearers, while coalface roof supports were either powered supports or posts and bars. The Bute seam was being worked at a thickness of 1.27 metres, with the coalface length being 220 metres, and cutting and loading of the coal by Gleithobel plough. The Gellideg seam was worked at a thickness of 1.45 metres and a coalface length of 190 metres.

Coal Cutting and loading were by ranging drum shearers and the roof supports were post and bars. The Lower-Six-Feet coalfaces were prefixed with the letter S, the S10 had been closed by February 1981 while the S11 was advancing on two coaling shifts per day at an advance of 1.4 metres. This coalface had a life of 150 metres to a fault and then another 360 metres after that. The Lower-Nine-Feet seam coalfaces were prefixed by the letter M, the M16 was advancing 1.6 metres per day on double shift and was expected to close in August 1981. The M17 was to replace this coalface advancing 1.8 metres per day on double coaling with a life of 470 metres. The coalfaces in the Gellideg seam were prefixed with a letter G, the G38 was advancing 1.7 metres per day on three coaling shifts with a life of 250 metres. The output of coal per man shift on the coalface was expected to be 4.3 tonnes, and overall for the colliery, it was expected to be 1.74 tonnes. The saleable yield of coal was 60% of the total production. Manpower distribution at that time was; working at the coalfaces, 264 men, developing new coalfaces, 84 men, other work underground, 211 men, working at the surface of the mine, 122 men. The manager of that time, T.M. Bond, complained to his superiors that he needed one hundred more men if he was to complete the development programme. At this time the NCB was investing heavily into this pit to reach an estimated 20 million tonnes of coal reserves, it also bore down in eleven different places in an attempt to prove new areas. It all came to nothing. In 1983 this colliery was losing £40.20 for every tonne of coal that it produced, the third worst figures in the South Wales Coalfield.

When the NCB and NUM failed to agree at the local level over a particular matter, often assessors, consisting of one man from the NUM and one man from the NCB, would come into the pit and adjudicate on the matter. To give an insight into this system I have set out below part of a report into a protective clothing application at St. John’s that occurred in 1984:

The Assessors were I.J. Jones of Industrial Relations at Llanishen, and R. Williams, South Wales NUM Executive Council Member. “The Colliery was visited on Friday, 10th February 1984, to investigate and report on a claim for protective clothing (cold weather underwear and donkey jackets) for workmen employed in both the South and North Pits.” Out of 10 applications three were rejected and seven accepted, examples of both are; “At point (a) the Assessors noted that the South Pit was the Colliery upcast shaft and that the flow of air was primarily via the pit bottom slum roadway this being the opposite side of the shaft to the point where the hitchers controls were sited, at this site the Assessors felt conditions were normal and not so cold as to warrant a donkey jacket and rejected the claim as a consequence The S Bunker was sited a short distance inbye of the North Pit bottom the attendant was already in receipt of a donkey jacket, the Lodge, however, felt that the jacket alone was insufficient protection against the cold. The Assessors agreed that there was merit in the union’s argument and recommended that the workmen at this point be granted an issue of cold weather underwear.”

In August 1984, fifty members of NACODS, the supervisors union carried out a 36-hour sit-in at this colliery protesting at what they claimed was intimidation by NUM members. They left following guarantees from the NUM pickets. Four NUM members at this pit were dismissed by the NCB during the 1984/85 miner’s strike for what the NCB called internal disciplinary reasons.

Following the 1984/5 Miner’s Strike, St. John’s Colliery only attained 51% of expected production figures by the end of April. The B 1 Coalface was suffering from poor roof and wet conditions, and there were problems with the new S12 Coalface. In April 1985, the coal board said that the pit had become impossible to work successfully as a result of hopeless geology and because productivity had slumped to the lowest rate in the coalfield. On the 7th of May 1985, the NCB’s Area Director visited the pit and announced that redundancies would begin immediately. The NUM Lodge agreed to a slim-down of around 300 to 350 men but opposed closure and was the first to apply to the Modified Review Procedure. However, this was to no avail and the colliery closed in November 1985. It was the last deep mine to work in the Llynfi Valley.

Some Statistics:

- 1909: Manpower: 264.

- 1910: Manpower: 391.

- 1911: Manpower: 331.

- 1912: Manpower: 614.

- 1913: Manpower: 638.

- 1915: Manpower: 638.

- 1916: Manpower: 638.

- 1919: Manpower: 600.

- 1920: Manpower: 600. Output: 216,858 tons.

- 1922: Manpower: 1,370.

- 1923: Manpower: 1,399.

- 1924: Manpower: 1,473.

- 1925: Manpower: 1,400.

- 1927: Manpower: 1,181.

- 1928: Manpower: 968.

- 1930: Manpower: 726.

- 1933: Manpower: 1,298.

- 1935: Manpower: 726.

- 1937: Manpower: 1,388.

- 1938: Manpower: 1,424.

- 1940: Manpower: 1,480.

- 1945: Manpower: 1,142.

- 1947: Manpower: 1,161.

- 1948: Manpower: 1,130. Output: 240,000 tons.

- 1949: Manpower: 1,140. Output: 240,000 tons.

- 1950: Manpower: 1,086.

- 1953: Manpower: 1,080. Output: 300,000 tons.

- 1954: Manpower: 1,086. Output: 368,543 tons.

- 1955: Manpower: 1,017. Output: 294,000 tons.

- 1956: Manpower: 985. Output: 253,656 tons.

- 1957: Manpower: 958. Output: 246,518 tons.

- 1958: Manpower: 970. Output: 257,772 tons.

- 1960: Manpower: 907. Output: 333,635 tons.

- 1961: Manpower: 843. Output: 345,248 tons.

- 1964: Manpower: 885.

- 1969: Manpower: 801.

- 1970: Manpower: 839.

- 1971: Manpower: 832.

- 1972: Manpower: 811.

- 1974: Manpower: 690. Output: 251,000 tons.

- 1978: Manpower: 849. Output: 230,000 tons.

- 1979: Manpower: 818. Output: 188,000 tons.

- 1980: Manpower: 821. Output: 188,458 tons.

- 1981: Manpower: 814.

- 1984: Manpower: 881.

- 1985: Manpower: 888.

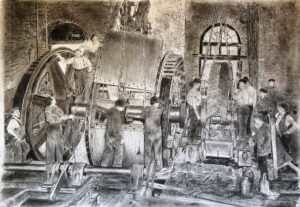

St John’s Colliery – Dismantling of the colliery winch mechanism. A drawing by Peter Roy Wiles and used here with his permission

AN EXAMPLE OF A 1985 CLOSURE – ST. JOHN’S COLLIERY

St. John’s Colliery had been sunk in 1910 by North’s Navigation Collieries (1899) Limited and had worked with varying levels of success through to the great miner’s strike of 1984/85. By 1984 the pit had exhausted most of the more profitable seams and was starting to incur great losses, claimed by the NUM to be due to deliberate NCB tactics, and claimed by the NCB to be due to geological conditions. Nevertheless, in 1984 the pit was losing £40.20 for each ton of coal it produced (the third worst figure in the Coalfield), with the 881 miners at the pit producing 3,354 tons of coal weekly, giving a loss of £153 per week for each miner at the pit (the second worse figure in the Coalfield).

A review meeting on the pit was held at the Coal Board’s headquarters at Llanishen, Cardiff on the 27th of February 1984 in which the NUM claimed that the NCB was conditioning the Colliery for closure, and the NCB suggested the closing of the South pit and concentrate all work hi the North pit, which the NUM claimed would sterilise future reserves in the Margam area and lead to the eventual closure of the colliery. At a meeting of the Executive Council of the South Wales Area of the NUM to following day it was decided to ‘pressurise the Board into driving two headings into the Margam take which would mean many years of life for the colliery.’

It was against this background that, understandably, the NUM Lodge launched itself wholeheartedly into the strike that exploded less than a week later. As the strike dragged on into January 1985 an incident at the pit involving ‘scabs’ and the NUM resulted in the lodge officers’ being dismissed, it was the only occasion that lodge officers were dismissed in South Wales. In early March 1985, the strike collapsed and the miners returned to work apprehensive over their future. St. John’s Colliery had a poor resumption to work and at the Area Consultative Meeting held on the 22nd of April 1985 it was stressed that St. John’s was in serious difficulties with an output per manshift of less than 0.5 tonnes, the worse in the Coalfield. A detailed report was later given on the colliery which stated “The B1 face was affected by a very poor roof and wet conditions, though there had been a slight improvement in the previous week. Production had now started on the S12 face but it was experiencing problems; 51% of normal production had been achieved.”

Generally, throughout the Coalfield the men had returned to work resigned to the fact that the Coalfield would be destroyed, they believed not on economic grounds, but as an act of political vengeance, the so-called ‘face-saving’ Modified Review Procedure that was the basis for the return to work was a sham, with all its talk of an Independent Body, the final paragraph stated “At the end of this procedure the Board will make its final decision.” Yet, probably for public relations purposes the NCB did everything possible to prevent pits from reaching that level, most were run down and starved of investment, unrealistic targets were set for output levels, and if the pit attained these, higher ones were then set. Large amounts (for a working man) of redundancy payments were offered, an incredible temptation to men who had gone a year without pay, then The board would announce that the next year’s redundancy payments would probably be lower, panicking the men to accept the inevitable earlier than was necessary. This ploy was still in use in 1990 when the threat of less redundancy pay made the men at Oakdale Colliery accept early closure. The early retirement of the Area Director, Phillip Weekes, heralded a new system of hard-line management, ably supervised by the new Director, CL Davies. The old type of colliery manager disappeared into ‘retirement’ and young men were promoted to replace them. Where Mr. Weekes appeared to have promoted the Coalfield and fought his corner, Mr. Davies and his type appeared to ruthlessly carry out the dictates of Hobart House, eventually doing themselves out of a job. C. Davies was still Deputy Director when on the 1st of April 1985 he visited St. John’s Colliery and announced that later that week he would be giving his views on the future of the pit, in an attempt to pre-empt a closure announcement the NUM Lodge at the colliery stated that they were prepared to let over 300 men go out on redundancy, priority would be given to redundancies for men over 50 years of age and those with serious health problems. The lodge argued that it was better to retain a measure of control over a reduction in manpower rather than allow the Board to decide the future of the pit with no consultation. The Area Executive Council of the NUM expressed disquiet at the lodge’s move which had been done without consultation with them. They claimed that there had not been sufficient involvement by the miner’s agent or the union’s engineers.

On the 7th of May, C.J. Davies again visited the colliery and announced that he would implement redundancies, but by then the men had decided to fight closure and the case was to be forwarded to the National Union for discussions at the national level. The local lodge also decided to carry out a public campaign to gain support for keeping the colliery open, Neil Kinnock and other leading opposition MP’s were asked for support, and a videotape was made putting the union’s case for retention of mining at St.John’s. Despite the campaign by the lodge, the men at the pit were ‘voting with their feet’, and in that week 400 disillusioned men had accepted redundancy terms. The lodge continued to fight to keep the pit open, now with reduced manpower, and in July held a ‘public inquiry’ at Cardiff to gain publicity for their cause. This again caused disquiet amongst the Area Executive Council who complained that they were not being fully informed of developments. In September, St John’s case, at last, reached the national review meeting in London, the NUM took 75 minutes presenting the reasons to keep the colliery open, however, their arguments fell on deaf ears, the NCB’s response ‘was not more than a few sentences’. However, they did agree that St. John’s would come under the new Modified Review Procedure, the first pit in South Wales to do so. September rumbled on into October and a report to the AEC of the NUM stated “to accept a report that the decision on the closure of St. John’s had been delayed for a further period until the nature of the independent review body had been agreed and established.” At the Area Conference of the NUM held on the 18th of October, the St John’s representative reported that one of the big problems facing NUM Lodge Committees was the speed with which they were being confronted with NCB initiatives. Lodges were being snowballed into making rash decisions on vital matters.

By the end of October the NUM and NCB at the national level had still not agreed on a formula to work the Modified Review Procedure, and the Board had intensified its campaign of ‘dirty tricks’ at the colliery, enticing the men who did not want redundancy to go to other pits in south Wales where ‘their future would be secure.’ The NCB had unilaterally rejected the NUM’s appeal over the closure of St John’s and negotiations were at a stalemate. At a General Meeting of the St. John’s NUM Lodge held on Thursday, 21st of November 1985 the membership reluctantly accepted the inevitable and agreed to the closure of the last deep mine in the Maesteg area. The main concern was that the NCB had given an ultimatum that the following day would be the last one in which they would be prepared to process redundancies, if they refused to do this work the men who were forced to finish would not receive the Social Security benefits normally due to them, this coupled with the failure to advance in the review procedure, and the Area President’s statement that there wasn’t a ‘magic formula’ either on the question of benefits or on the question of being able to introduce into the Modified Review Procedure factors concerning social hardship and that nothing could be given to give comfort or hope to the men of St. John’s Colliery.

CWMDU COLLIERIES

Near Maesteg, Llynfi Valley.

A name attached to numerous levels that worked in this area for coal and iron ore. Owned in turn by the John Brogden and Sons (1865/9), the Tondu and Maesteg Steam Coal Company in 1874, the Llynfi, Tondu and Ogmore Iron and Coal Company, and North’s Navigation Collieries (1899) Limited.

- On the 16th of May 1868, T. Jones, aged 34 years, and a collier, was killed by an explosion of gas,

- On the 16th of May 1868, W. N. Margrieve, aged only 14 years, and a collier, was killed by a fall of the roof.

- On the 27th of April 1874, E. Jones, aged 40 years, and a collier, was also killed by an explosion of gas.

The closure dates for at least fifteen levels range from 1899 to 1926.

In 1896 the Cwmdu Middle Level was owned by the Main Colliery Company of Neath and employed 7 men underground and 1 man on the surface with the manager being Richard Thomas. The Cwmdu Nos. 2,3,8 worked the Victoria seam which was abandoned before June 1884. The Cwmdu Nos.4,8,11,12,13,14,15,16,17 were worked for ironstone. The Cwmdu No.19 worked the Yard seam. The Cwmdu, (Cenol) Nos.14,16,17 worked the Upper Black Band ironstone vein. The Cwmdu Maesteg Nos. 3,8, Coegnant Nos.3,4,8,13, Maesteg No.9, and Tywith No.8 all worked the Lower Black Band ironstone vein and were abandoned in November 1884.

The Cwmdu Maesteg Nos.7,8,11 worked the Victoria seam and was abandoned in October 1908. The Cwmdu Maesteg Nos.8,11, Caedefaid No.9, Coegnant Nos. 2,3,13 worked the Two and a Half Feet seam which was abandoned in October 1908. This location became the site of St. John’s Colliery.

Information supplied by Ray Lawrence and used here with his permission.

Return to previous page