The Blaenant Colliery Company was incorporated in 1930 to work the Blaenant Drift which was driven into the No.2 Rhondda seam that had a section of 1.32 metres in its take. This company was based at 24 Exchange Buildings, Swansea with the directors being; David Jeffreys, D.N. Morgan, Lewis Lewis, T.R. Davies and W.A. Hughes. This was its only mine. The mouth of the drift was near the Cefn Coed Colliery and by 1935 Blaenant was in full production employing 120 men underground and 20 men on the surface producing 52,000 tons of coal. In 1943/5/9 it employed 133 men underground and 51 men on the surface with the manager being O. Jones.

The Blaenant Colliery Company was incorporated in 1930 to work the Blaenant Drift which was driven into the No.2 Rhondda seam that had a section of 1.32 metres in its take. This company was based at 24 Exchange Buildings, Swansea with the directors being; David Jeffreys, D.N. Morgan, Lewis Lewis, T.R. Davies and W.A. Hughes. This was its only mine. The mouth of the drift was near the Cefn Coed Colliery and by 1935 Blaenant was in full production employing 120 men underground and 20 men on the surface producing 52,000 tons of coal. In 1943/5/9 it employed 133 men underground and 51 men on the surface with the manager being O. Jones.

The colliery came under the control of the National Coal Board in 1947 and was placed in the South Western Division’s No.1 Swansea Area but by 1954 it had been moved to the No.9 Neath Area, No.1 Group and in that year produced 76,000 tons of coal. In December 1954 new pit head baths were opened at a cost of £21,051. This colliery which had its own coal preparation plant in 1956 employed 117 men at the coalfaces out of a total manpower of 268.

In 1957 it employed 102 men underground and 60 men on the surface with an output per man shift of 31 hundredweights. It was proposed to drive a new drift into the workings from the Cefn Coed washery and double shift the colliery. By 1961, 232 men worked at this colliery, 99 of them at the coalfaces. The No.1 Group was never the largest of groupings in the NCB, consisting of Blaenant, Cefn Coed, Glyncastle and Ffaldydre in 1961 employing 1,285 men and producing 267,704 tons of coal. The Group Manager was H. Jarman with the Area Manager being C. Round. In 1964 the NUM Lodge Secretary was H.E. Lewis. In 1969 A.B. Griffiths was the colliery manager and this colliery employed 300 men working underground and 26 men working at the surface of the mine. Mr. Griffiths was still the manager in 1978 while A.R. Jones was the manager in 1979/80.

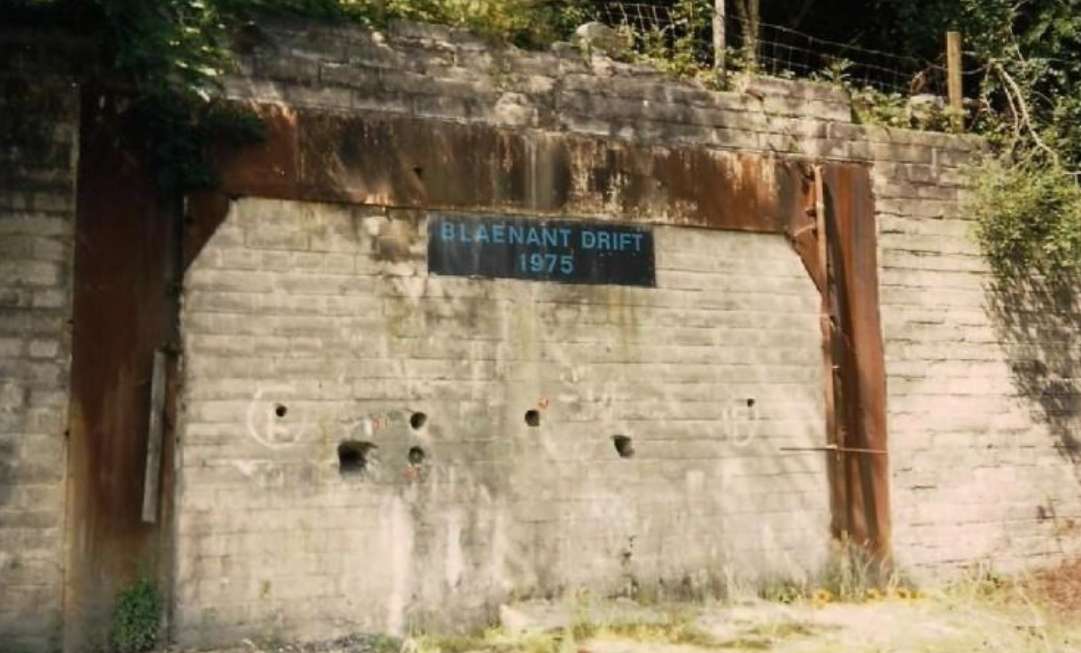

In 1971 a New Drift with a conveyor reaching almost 600 metres into the mine was driven into the same seam replacing the older drift driven in 1963. The new drift shortened the coal routes to the surface of the mine by 2,250 yards. The coalfaces were to be worked by the retreat system and three Dosco Heading machines had to tunnel 4,000 metres until the new ‘faces could be opened. The workings which were originally to the south and east of the drift, now changed direction to the north and west. The new drift cost £1.4 million and dipped down at a gradient of 1 in 3.7. It could accommodate a manriding train equipped to carry 120 men, plus the coal conveyor which could handle 600 tonnes of coal per hour.

In 1971 a New Drift with a conveyor reaching almost 600 metres into the mine was driven into the same seam replacing the older drift driven in 1963. The new drift shortened the coal routes to the surface of the mine by 2,250 yards. The coalfaces were to be worked by the retreat system and three Dosco Heading machines had to tunnel 4,000 metres until the new ‘faces could be opened. The workings which were originally to the south and east of the drift, now changed direction to the north and west. The new drift cost £1.4 million and dipped down at a gradient of 1 in 3.7. It could accommodate a manriding train equipped to carry 120 men, plus the coal conveyor which could handle 600 tonnes of coal per hour.

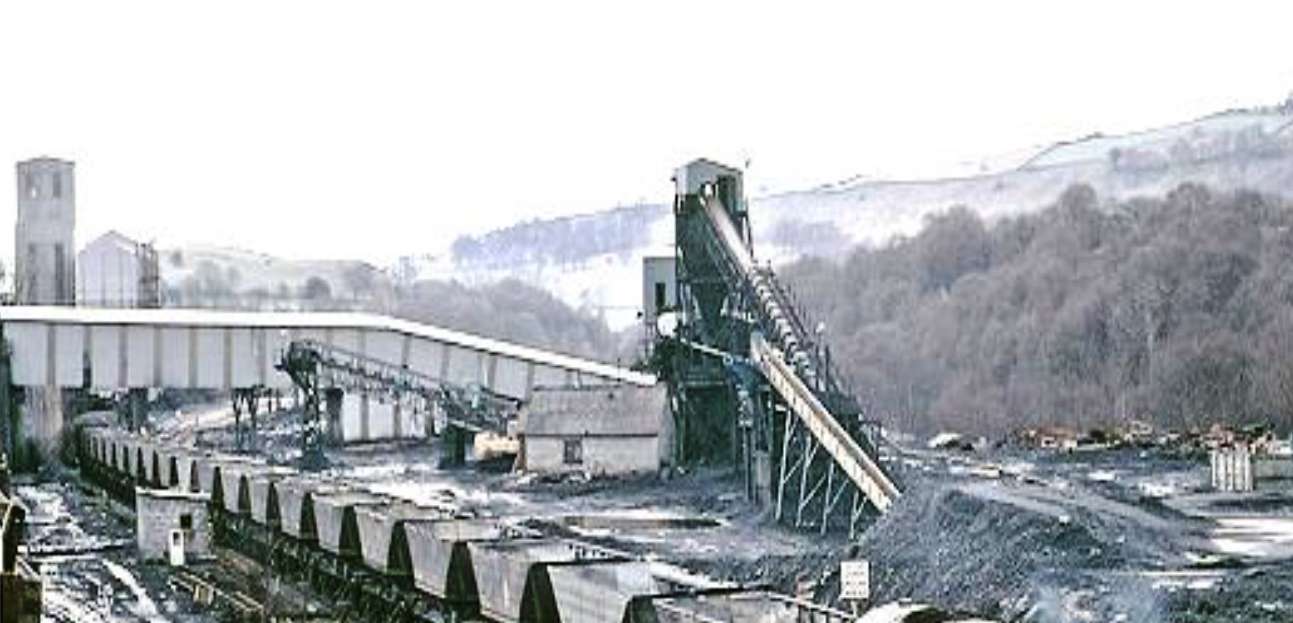

At the surface of the mine a whole train load of 32 wagons (1,000 tonnes of coal) destined for Aberthaw Power Station could be loaded in 25 minutes by the ‘merry go round’ system. Loading, transporting 50 miles and discharging took only three hours. This colliery was a regular record breaker in a mineral take that was virtually fault free, a fault free geological take is unknown in the rest of the South Wales Coalfield.

During the 1972 miner’s strike for more wages, this mine was almost flooded and only the intervention of volunteer striking miners and management saved it. The Times newspaper of the 16th of January 1975, stated; “A £15m scheme to turn the Blaenant Colliery, Dulais Valley, near Neath, into one of the most profitable and productive mines in Britain, was announced by the National Coal Board at Cardiff yesterday.” In 1978 it was the first mine in south Wales to be equipped with three coal cutters on a 650 feet long coalface which was titled the ‘106’. Production then increased from 3,000 tons to 5,000 tons per week from this face. At that time the workings were 1,500 feet under the surface with ten miles of roadways and three miles of conveyors in use. The output per manshift was 8.2 tonnes at the coalface and 3.3 tonnes overall for the colliery. The NCB estimated nine million tonnes of coal reserves for this colliery. As part of the industrial relations process when no agreement could be made at local level, assessors were brought in who consisted of one NUM and one NCB representative. They were called into this colliery in June 1979 to assess the expected advances in the 109’s coalface drivage. This coalface was between 60 inches to 78 inches thick and the drivage was 15 feet wide. Three shifts were worked per day with three men on each shift. The advance was settled at 26 yards per week. In 1981 coalface length varied from between 109 and 200 metres, with coal cutting being done by ranging drum shearer and coalface supports were the self advancing types, output per manshift on the coalface was expected to be 9.66 tonnes, and overall at 3.83 tonnes. Daily advance was expected to be 2.43 metres on double shift coaling. At the beginning of that year the 108 coalface had a life of 660 metres, the 109 had 710 metres, the 110 had a life of 1,010 metres with the 111 coalface planned to open in 1982 with a life span of 1,370 metres. The saleable yield of the coal produced was 90%. Manpower deployment at that time was; development, 50, surface, 116, coalface, 205, elsewhere below ground, 146.

In 1983 this colliery was losing £15.80 per ton while employed 698 men. Following the miners’ strike of 1984/85 this colliery had adverse conditions on both of its coalfaces, the 111’s had poor roof conditions, and the 112’s was affected by a fall of roof. By the end of April 1985 output was only 66% of expected levels. In 1988 590 men produced 500,000 tons of coal. The NUM Lodge Secretary in 1977 and 1981 was Ben Davies, and in 1984 it was H. Davies. Ben Davies also served on the South Wales Executive Council of the NUM. The class of coal produced at Blaenant Colliery was Dry Steam mainly for Aberthaw power station.

In April 1990 Terence Wheatley, South Wales Group director, stated that output at Blaenant was below half of what was expected and due to the geology there was no hope of hitting the target of 15,000 tonnes a week, the break even figure. The mine had lost he past year. Phil Bowen the NUM lodge secretary at Blaenant was adamant that there were vast amounts of coal left but the NCB was not interested in working them. Just over 600 men were working at the mine. The Colliery was closed by British Coal on the 11th of May 1990. On closure it had ten miles of underground roadways and three miles of conveyor belts.

Some Statistics:

- 1933: Manpower: 123.

- 1934: Manpower: 170. Output: 52,000 tons.

- 1937: Manpower: 175 1938: Manpower; 176.

- 1940: Manpower: 175. Output: 70,000 tons.

- 1944: Manpower: 190.

- 1948: Manpower: 185 Output: 75,000 tons.

- 1949: Manpower: 185. Output: 75,000 tons.

- 1950: Manpower: 191.

- 1953: Manpower: 200 Output: 84,000 tons.

- 1954: Manpower: 168. Output: 76,001 tons.

- 1955: Manpower: 226. Output: 60,711 tons.

- 1956: Manpower: 268. Output: 83,905 tons.

- 1957: Manpower: 262. Output: 97,906 tons.

- 1958: Manpower: 250. Output: 86,879 tons.

- 1960: Manpower: 243. Output: 83,428 tons.

- 1961: Manpower: 232. Output: 67,987 tons.

- 1965: Manpower: 528.

- 1969: Manpower: 326.

- 1970: Manpower: 589.

- 1971: Manpower: 616.

- 1972: Manpower: 642.

- 1974: Manpower: 631 Output: 376,000 tons.

- 1978: Manpower: 591. Output: 451,230 tons.

- 1980: Manpower: 668. Output: 333,762 tons.

- 1981: Manpower: 517.

- 1985: Manpower: 642.

- 1989: Manpower: 670.

- 1990: Manpower: 718.

Information supplied by Ray Lawrence and used here with his permission.

Return to previous page