Pontypool, Afan Lwyd Valley (ST 2471 9995)

Pontypool, Afan Lwyd Valley (ST 2471 9995)

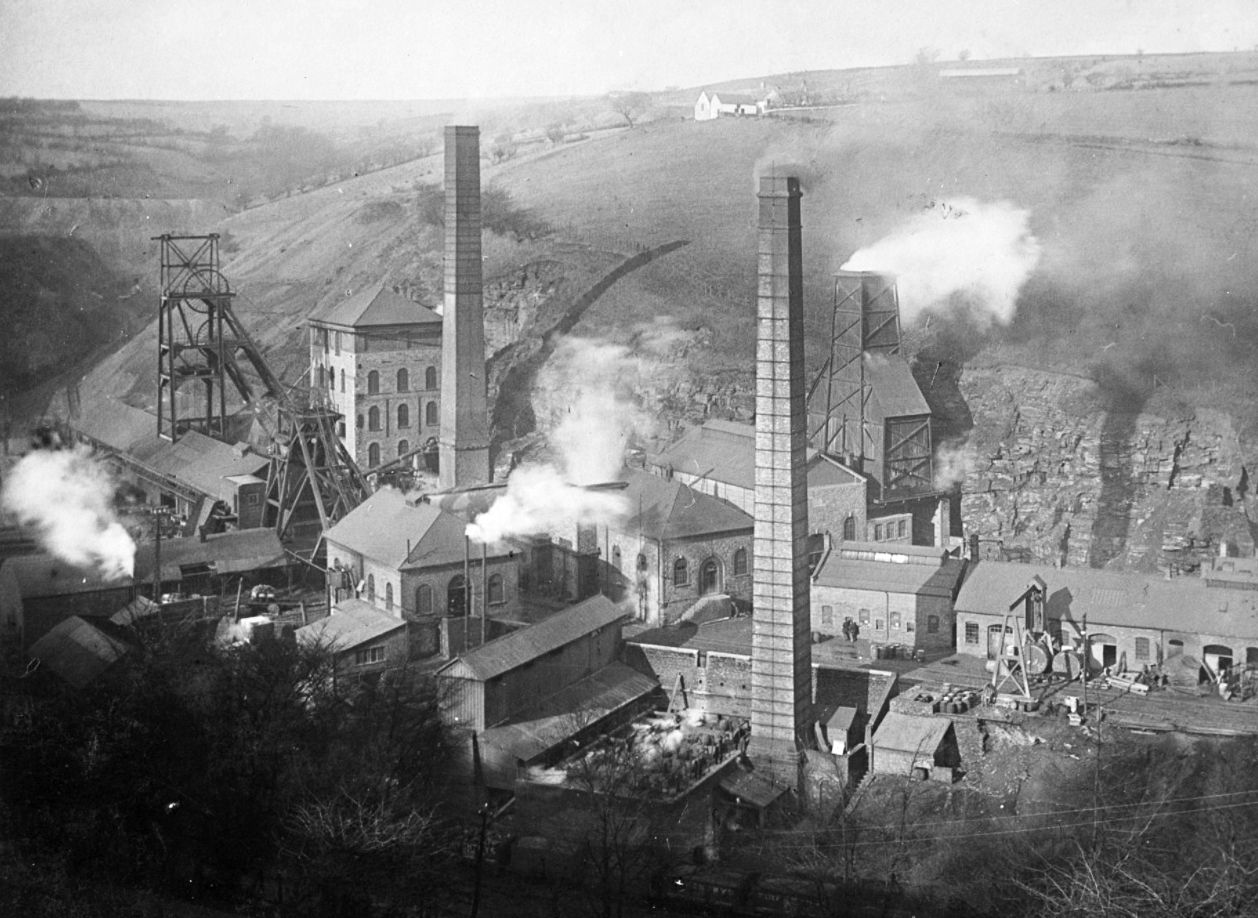

This colliery was sunk between 1878 and 1881 to the Tillery (Brithdir) seam and deepened to the steam coal seams of the Middle and Lower Coal Measures in 1892. The No.1 downcast shaft was 16 feet in diameter and 442 yards deep to the Nine-Feet seam, it was the main winding shaft with a single deck carriage bearing two trams per wind giving 800 tons per shift. The upcast (No.2) shaft was 14 feet in diameter and 426 yards deep and could only wind a single tram. This colliery had a vertical winding engine made by Daglish on the one pit (No.1) with the headgear wheels being one above the other instead of the usual side by side system. In 1902 the upcast was only used for winding from the Big Vein at a depth of 395 yards. The manpower for this pit was 140, while 760 men descended the downcast shaft. Daily output was 1,200 tons of coal, 1,050 coming from the Black Vein (downcast) and 150 tons of coal coming from the Big Vein (upcast shaft). Ventilation was by a Walker type steam-driven fan which produced 200,000 cubic feet of air per minute. It was 24 feet in diameter.

Tirpentwys Colliery was opened by Darby and Norris who established the Tirpentwys Colliery Company which was incorporated as the Tirpentwys Black Vein Steam Coal and Coke Company in 1888. In that year this colliery was working the Meadow Vein (Yard/Seven-Feet) with the manager being B. Nicholas. The workings in this seam had reached their north-eastern limits by 1892, the eastern limit had been reached by 1890, the southern limit was reached by 1892 and the western boundary was reached in 1895. In 1896/1900 the manager was B. Nicholas and the pit was working the Tillery and Black Veins.

On the 8th of October, 1902, eight men, who had been working in the Big Vein Seam, were killed when they were thrown out of the ascending cage. The full report can be found here.

In February of 1909, there was a considerable reconstruction of the No.1 Pit with new headgear, winding engines and carriages changed from single to double-decked. In 1913/15 the manager was G.W. James. The Tirpentwys Company was a member of the Monmouthshire and South Wales Coal Owners Association and in the 1920’s it became a subsidiary of the Ebbw Vale Steel, Iron and Coal Company Limited. In 1934 the directors were G.W. James, J.H. Robinson, R.C.T. Laybourne, A.E. Jones and E.N. Nicholas. The company secretary was Ivor Jones. In 1935 the Ebbw Vale Company sold off their mining interests to Partridge, Jones and John Paton Limited.

In 1935 Tirpentwys employed 220 men working on the surface of the mine and 1,220 men underground working in the Black Vein (Nine-Feet), Meadow Vein (Yard/Seven-Feet) and Big Vein (Four-Feet) seams.

From 1918 to 1945 the manager was T.P.S. James. In 1943 this pit employed 850 men working the Big, Black and Meadow Vein seams and 209 men working at the surface of the mine.

On the 30th of July 1935 a fire broke out in the shaft near the top of the No.1 Pit. Due to the smoke and fumes going down the pit all the men had to be evacuated and the ventilating fan stopped. It was found that oil and grease that had accumulated under some boarding near the bank had ignited. The fire was quickly extinguished but all work ceased for two days as a precautionary measure.

In June 1937 Partridge Jones and John Paton made the initial offer to buy this colliery of £15 for each £10 share.

On Nationalisation of the Nation’s coal mines in January 1947, Tirpentwys Colliery was placed in the National Coal Board’s, South Western Division’s, No.6 (Monmouthshire) Area, and at that time employed 205 men on the surface and 817 men underground working the Big Vein, Black Vein and Meadow Vein seams.

The colliery had its own coal preparation plant (washery) and was the site for a wagon repair workshop. The manager was still T.P.S. James. In 1950 the NCB estimated reserves of 11,203,000 tons of coal not including the Garw seam. At that time the colliery was pumping up one million tons of water per day. In 1954/55 this colliery was one of 42 that caused concern to both the NUM and the NCB over the high level of accidents. In 1956 out of the total colliery manpower of 911 men, 353 of them worked at the coalfaces.

In 1959 Tirpentwys Colliery became part of the £5.5 million development of Hafodyrynys New Mine, with Tirpentwys’ coal being diverted by underground roadway to the Hafodyrynys washery, and the Tirpentwys surface plant was dismantled.

The Times newspaper in April 1959 reported:

A visit to the Tirpentwys Colliery showed how mechanization has revolutionized mining below ground as well as above. No longer is it a matter of crawling on hands and knees along narrow passages. Entry to the colliery is by a drift, 1,300 yards long, sloping into the earth at a gradient of one in four. More like the Blackwall Tunnel than the entrance to a coal mine, this drift, 12 ½ ft high and 15ft wide, was driven at an average speed of 27.6 yards per week, believed to be a British record for this gradient.”

In July 1969 this colliery was placed on the NCB’s jeopardy (closure) list when output per man shift slumped to 16.6 hundredweights. The South Wales Coalfield average was 28 hundredweights.

This colliery was closed by the NCB on the 29th of November 1969 as a production unit but remained open in the 1970s for pumping and ventilation purposes for Blaenserchan Colliery. At the time of closure, G.E. Griffiths was the manager.

Generally, this colliery produced type 501 High Volatile Coals, medium to strong caking, with a low ash and sulphur content. These coals were mainly used for coking blends.

From its sinking to nationalisation in 1947 there were 64 fatal accidents at this colliery, including two who were killed under a fall of roof in 1910 and the eight who were killed in 1902 when the winding carriage became detached from the rope and fell down the shaft. These are some of them:

- 8/09/1910, George Bailey, Age: 37, Rope splicer, Owen Roberts, Age: 41, Labourer : Fall of roof on a haulage road. A pair of timbers and a pulley frame were knocked out by a journey of trams leaving the rails, and while the place was being repaired a large fall occurred discharging 6 pairs of timbers. Two other men were injured. 2 killed.

- 6/12/1912 , Percy Albert Lewis, Age: 23, Haulier: He was overpowered and killed by a tram which he tried to stop

- 21/11/1913, Rupert Price, Age: 26, Collier: Fall of side at the working face. In pulling down coal and clod a post was discharged. The post in falling struck him in the forehead causing a fractured skull.

- 25/02/1914, Frederick Gilbert Ford, Age: 16, Collier boy: He stumbled over a fallen post and slightly hurt his foot and arm. He died of blood poisoning on March 15th, 1914.

- 3/06/1915, Edward Harris, Collier: Roof fall.

- 23/05/1916, Percy Davies: Collier: Timber fell on head.

- 10/01/1918 , Arthur Hassell, Collier: Fall of clod.

- 7/02/1918, Alfred Cutter: Collier: Roof fall.

- 12/03/1919, Richard Jones: Collier: Roof fall.

- 13/05/1919, George Brookes, Collier: Fall of quantity of stone.

- 19/03/1920 , William Davies, Collier: Fall of coal and clod.

- 2/11/1921, Augustus Bowen, Collier: Roof fall.

- 10/12/1921, William Webb, Fell down shaft.

- 27/01/1922,George Pearce, haulier: Kicked by a horse.

- 27/03/1923, Sydney Johns, haulier: Crushed by trams.

- 11/08/1923, William James, Collier: Fall of rubbish.

- 18/01/1924, Albert Thomas, Collier: Fall of coal.

- 9/11/1925, James Weeks, haulier: Crushed by a tram.

- 11/11/1925, John Hooper: Collier: Roof fall.

- 17/12/1925, George Hoffman, Age: 50, Collier: Fall of coal. Died 19th.

- 5/02/1926 , James Evans, Collier: Fall of rubbish.

- 8/10/1927, Cyril Bessell, Collier: Fall of stone.

- 3/04/1929, William Benjamin Dowding, Age: 39, Stoker: Came out of pump room and passed under bridge where a workman was throwing bricks to the boiler house, one of them bricks caught his head. Died 5th.

- 16/10/1929, Morgan Williams, Age: 62, Haulier: killed by a horse.

- 30/03/1929, Joseph Pepler: Strain – brain haemorrhage.

- 17/11/1933, William Woolfall, Age: 34: Collier: Fall of stone.

Some Statistics:

- 1894: Output: 177,152 tons.

- 1896: Manpower: 821.

- 1899: Manpower: 857.

- 1900: Manpower: 948.

- 1901: Manpower: 959.

- 1902: Manpower: 1,024.

- 1903: Manpower: 1,036.

- 1905: Manpower: 1,330.

- 1907: Manpower: 1,241.

- 1908: Manpower: 1,350.

- 1909: Manpower: 1,350.

- 1910: Manpower: 1,332.

- 1911: Manpower: 1,371.

- 1912: Manpower: 1,285.

- 1913: Manpower:1,422.

- 1915/6: Manpower: 1,422.

- 1918: Manpower: 1,541.

- 1919: Manpower: 1,535.

- 1920: Manpower: 1,535.

- 1923: Manpower: 1,670. Output: 400,000 tons.

- 1924: Manpower: 1,755.

- 1925: Manpower: 1,650.

- 1927: Manpower: 1,460.

- 1928: Manpower: 1,751.

- 1930: Manpower: 1,730. Output: 400,000 tons.

- 1931: Manpower: 1,750.

- 1932: Manpower: 1,400.

- 1933: Manpower: 1,455.

- 1934: Manpower: 1,308.

- 1935: Manpower: 1,440.

- 1937: Manpower: 1,346.

- 1938: Manpower: 1,401.

- 1940: Manpower: 1,400. Output: 400,000 tons.

- 1945: Manpower: 1,059.

- 1947: Manpower: 1,022.

- 1948: Manpower: 942. Output: 200,000 tons.

- 1949: Manpower: 996. Output: 249,000 tons.

- 1950: Manpower: 1,022.

- 1953: Manpower: 998. Output: 264,000 tons.

- 1954: Output: 205,000 tons.

- 1955: Manpower: 893.Output: 198,256 tons.

- 1956: Manpower: 911.Output: 216,428 tons.

- 1957: Manpower: 938.Output: 195,377 tons.

- 1958: Manpower: 920.Output: 222,512 tons.

- 1960: Manpower: 749. Output: 171,000 tons.

- 1962: Manpower: 723.

- 1969: Manpower: 686.

This information has been provided by Ray Lawrence, from books he has written, which contain much more information, including many photographs, maps and plans. Please contact him at welshminingbooks@gmail.com for availability.

Return to previous page