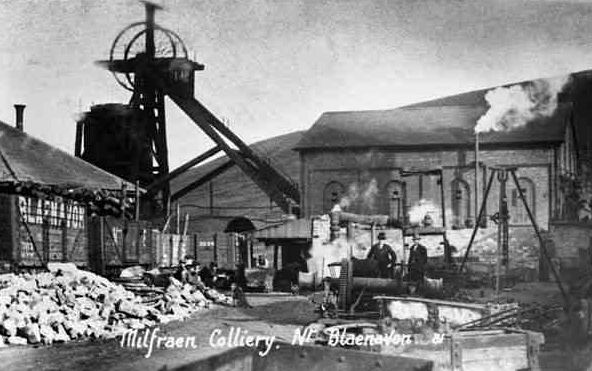

Blaenavon,Afan Lwyd Colliery (21841002)

This mine was situated three miles to the northwest of Blaenavon and opened pre-1870 by Jayne and Company and in that year it was called Milfraen Hill New Colliery. It was sunk to the Old Coal seam near to where it outcropped.

It was managed in 1878 by E. Evans and in 1888 by J. Williams when it was working the Bydelog seam. It was then temporarily closed and by 1900 in the hands of the Blaenavon Iron and Steel Company employed 23 men on the surface and 199 men underground working the Old Coal seam at Milfraen in that year. In 1913 it employed 553 men. The manager at that time was W. Waplington.

In 1916 it employed 619 men with the manager being F. Cartwright while in 1919 manpower had dropped to 463 men and the manager was now W. Lewison who was still there in 1930. In 1933 it was merged into Kay’s Slope. It was sunk to the Five-Feet/Gellideg (Old Coal) seam which it found at a depth of 215.1 metres.

The Four-Feet seam was struck at a depth of 140 yards, and the Nine-Feet seam at a depth of 188 yards. The shaft was elliptical in shape 16 feet by 12 feet and had an upcast ventilation pit for both Milfraen and Kay’s Slope which was the intake ventilation way for both workings. The ventilation of the workings was produced by a Schiele, double inlet fan, placed near the top of the Milfraen Pit and this was capable of producing 75,000 cubic feet of air per minute at a water gauge of 3 inches. The upcast pit head frame at the Milfraen Pit was enclosed by a wooden casing in which sliding doors were operated by the movement of the cages in their ascent and descent of the pit.

On the 4th of March 1902, five miners were killed when they fell down the shaft. They were thrown out of the cage while ascending when the cage struck against one of the iron girders about 78 yards from the pit bottom. The Inspector of mines believed that there was a lot of slack rope and the cage was jerked from the pit bottom which caused swaying. Those that died were; Elias J Griffiths aged 13 years, Elias Griffiths aged 40 years, Edward Stallard aged 53 years, William A Stallard aged 15 years and David Phillips aged 37 years. David and Edward Stollard, father and son had only begun working at this colliery that same morning.

The Black Vein seam was first opened out in 1926 and was worked on a longwall system and later a mixture of longwall and stall workings. The seam was five feet ten inches thick with a roof of Horn Coal and a floor of rock.

In 1929 the total number of people employed in the Milfraen/Kay’s combine was 1,189 of which 113 were employed at the surface. Of this number, only 176 were at the Milfraen Pit and of these, 35 worked at the surface. The group of mines produced 10,150 tons of coal per week of which 1,150 were raised at the Milfraen Pit on two daily drawing shifts. The third shift was a repairing and coal-cutting shift. the day shift worked from 7 am to 3 pm, the afternoon shift from 3.30 pm to 11.30 pm and the night shift from 11.30 pm to 7.30 am.

The electricity produced at the colliery was supplied to a substation at the pit bank where 11,000 volts A.C. was transformed down to 3,000 volts A.C. and was again stepped down by an underground substation to 500 volts by two 100 K.V.A.. transformers. The power for these was used to drive a pump, haulage gears, coal-cutting machines and face conveyors in the mine.

The workings from Kay’s Slope were lit by naked lights but from the point in the return from these workings, open lights were prohibited, The workings of the Milfraen Pit were worked by locked safety flame lamps of the Davis (Derby) type and Oldham electric lamps.

The main and subsidiary haulages were operated through gears driven by electric motors. there were two haulages at the pit and the movement of trams on the haulage roads was controlled by a system of bare-wire electric signals with bells of an approved type. Each circuit was powered by six, quart-sized Leclanché cells but neither the bells or the signal wires were under suspicion of causing the explosion.

There was no shot firing in the Black Vein since the conditions did not render it necessary to fire shots. the roadways were generally damp and stone dusting was not necessary to dilute the comparatively small quantities of combustible material that was produced. The search for matches and smoking materials was carried out in the mine in a haphazard and negligent manner and no regular system, or a system approved by the Inspector was in operation at the colliery.

In July 1929, two conveyors were in operation which were known as ‘B’ and ‘C’ and there were 17 stall roads. The conveyor face was 80 yards long and it was operated by a jigging conveyor driven by an electric motor which dumped the coal into trams at the face of the man dip district. On the East side of the main dip, there was a series of ten-stall roads and the ’’B’ conveyor was outbye of this. The ‘B’ conveyor face was 60 yards long and operated by an electric jigger conveyor which dumped the coal into trams on the ‘B’ level. Between the ‘B’ conveyor face and the return airway, there were five stalls and a range of workings places known as ‘Mapstones’. The haulage of the coal from these places was by a haulage gear situated on the main dip of the district which hauled the journeys on to a parting close by and another haulage gear further outbye which took them to the shaft siding.

At 8.30 am on the 9th July 1929, there were 65 men working underground at this colliery when an explosion in the Mapstones District killed nine of them.

It was later found that the switch cover on the coal cutter was loose and probably that methane gas had seeped into the switch and had been ignited by a spark. Of the nine who lost their lives, four, Howells and Edmunds were at the coal cutter and Holder and Ricketts were at the face of Mapstone’s level. These men were killed outright. Parry, E. Williams, Barrel and A. Williams were found dead or dying some little distance out from their working places. Southcott made his own way out but died eight days later as a result of his injuries. Due to the stagnant and foul air, the bodies were brought out by rescue men wearing breathing apparatus and the last body was brought to the pit bank at 5 pm.

Those who died were:

- Evan Howells aged 40 years, coal cutting machine man,

- Clifford Edmunds aged 20 years, collier’s assistant

- Ernest Holder aged 57 years, collier,

- David Ricketts aged 35 years, collier,

- David John Parry aged 37 years, collier,

- Evan James Williams aged 20 years, collier’s assistant,

- Albert James Williams aged 21 years, collier’s assistant and

- Ernest Southcott aged 20 years, collier’s assistant.

The inquiry came to the conclusion that the point of origin of the explosion was near the cavity containing firedamp on the ‘B’ conveyor face and that the surrounding atmosphere contained firedamp. The movement of the air carried the explosive mixture towards the workings of Mapstone’s and past the electrical coal-cutting machine. It could have been ignited by sparks from the machine or from a spark produced by a pick striking a rail and the state of the machine when examined after the event was regarded as the most likely source of the ignition.

The inquiry found that there had been a breach of the Coal Mines Act, 1911 and the General Regulations.

The Corner summed up and submitted the following questions to the jury:

- Was the explosion of gas or coal dust or both?

- Where did the gas come from or accumulate?

- By what means was ignition produced?

- Was the explosion purely accidental?

- Was the explosion a result of the negligent acts or acts, omission or omissions of anyone?

- What where or were the acts of omission or omissions which conduced to the explosion?

- Who is responsible?

- Do you wish to make any recommendations? If so specify them.”

The jury answered the first four questions as follows:

- The explosion was one of gas.

- The gas was given off and accumulated at the fall at the top of the ‘B’ conveyor.

- The ignition of the gas was caused by a defective Hopkinson Coal Cutting machine.

- The accumulation of gas was caused by the inadequate ventilation resulting from the falls of roof on ‘B’ and ‘C’ conveyor faces.”

The jury answered question 5 by extending question 4:

“That the inadequacy of the ventilation was known or should have been known to the responsible officials That the accumulation of gas should have been ascertained by the fireman Jehu Morgan when he made his examination at or about 6.40 a.m. on the morning of the explosion

That on the morning in question the conditions in the said Mapstone section were such as they have rendered it unsafe for the men to be admitted to the working places therein.

That the condition of the said Hopkinson Coal Cutter machine was such the ’ opening spark’ within the meaning of the General Regulations as to the installation and use of electricity in the mine could not take place.

That No.123 (ii) and (v) of such General Regulations observance of which would, or might, have prevented the explosion was not complied with.”

The jury returned that the men met their deaths by misadventure and not otherwise and made the following recommendations to the Coroner:

- There should be a better system of packing the gobs.

- There should be an oil lamp in every working place.

- The coal cutter should be examined more often

- There should be better searching of the men before they go to their working places.

Those men who behaved heroically at the rescue attempt were O. Barson, timekeeper, Jesse Davies, mechanic, Herbert Daniel, fireman and D. Simmons, fitter.

Throughout its working life, nine miners died due to falls of the roof, two died through shaft incidents, one through a haulage accident, one due to a shot-firing mistake and two others for various reasons, some of them were:

- 16/01/1886, John Prisk, Age: 48: Sinker: Injured by a stone falling and died on the 26th.

- 3/10/1911, George Luff, Age: 15: Collier boy: Fall of the roof.

- 26/10/1911, Richard Hulbert, Age: 38: Haulier: Fall of the roof.

- 23/11/1911, William Hill, Age: 40: Master haulier: While waiting at the bottom of the shaft for the cage he slipped and fell forward, and the cage descended on him.

- 13/12/1912, William John Norman, Age: 14: Collier boy: Fall of coal

- 11/04/1916, John Davies: Died from a badly cut hand.

- 3/07/1916 John Edmunds: Fall of stone.

- 27/02/1917, Fred Southcote: The side of the workings fell in.

- 29/11/1924, William Gunter: Electric shock.

Production ceased in 1933, it was then used for ventilation purposes only until final closure in 1950.

Some statistics:

- 1899: Manpower: 188.

- 1900: Manpower: 222.

- 1910: Manpower: 539.

- 1912: Manpower: 638.

- 1913: Manpower: 553.

- 1915: Manpower: 663.

- 1916: Manpower: 619.

- 1919: Manpower: 463.

- 1920: Manpower: 573.

- 1923: Manpower: 494.

- 1924: Manpower: 629.

- 1925: Manpower: 771.

- 1926: Manpower: 30.

- 1927: Manpower: 69.

- 1928: Manpower: 153.

- 1929: Manpower: 152.

- 1930: Manpower: 204.

- 1932: Manpower: 25.

Information supplied by Ray Lawrence and used here with his permission.

Return to previous page