CWMBRAN MINE/SLOPE/No.2/ADIT

CWMBRAN MINE/SLOPE/No.2/ADIT

Cwmbran, Afan Lwyd Valley (270970)

The Four-Feet seam was proved, but not worked at a trial level 200 yards to the south of the Cwmbran Slope.

The collieries of the Cwmbran area were sunk primarily to feed the various and expanding works in the area. It all started off with the construction of an iron foundry in about 1800 and continued to grow as an industrial base, particularly its nut and bolt factory and associated works until it became part of the giant Guest, Keen and Nettlefolds empire (please see the owners section of this book). By the beginning of the Twentieth Century, Cwmbran had an impressive industrial portfolio that included; brick-works, tinworks, tube works, shovel works, wire works and the nut & bolt works.

With the advent of G.K.N. in 1902 their holdings in Cwmbran consisted of the Cwmbran Colliery with its washery, coke ovens and by-product plant, the Victoria Colliery, which as well as coal provided the clay for the brickworks, foundry and iron works, and the nut and bolt factory.

The Nos. 1 and 2 (Porthmawr) Levels were opened in 1837 by R.J. Blewitt who also worked for Fireclay. Blewitt, who was an extensive landowner, also owned the company shop, to bypass the Truck Act he let it out, but made it compulsory for his employees to trade there.

When Mr. Blewitt encountered financial difficulties in 1852 he sold the mines to John Lawrence. Lawrence then expanded by sinking the Cwmbran Mine Slope in 1854. The No.1 was closed in 1865.

The old Cwmbran drift intersected the Black Vein seam 500 yards from the entrance while it took the Adit 2,070 yards to meet this seam. It then worked for a distance of 1,266 yards. The fireclay beneath the Old Coal (Five-Feet/Gellideg) and Meadow Vein (Yard/Seven-Feet) seams was also extracted. Ventilation was by a 15 feet diameter Schiele-type fan.

Cwmbran Colliery mainly worked the Black Vein (Nine-Feet) seam at a section of about 144”, and for a distance of around 2 miles until a geological fault marked its boundary with the Celynen South Colliery. The South Wales Coalfield has a huge variety of different types of coal, from coking coals in the east, through the steam coals of the central areas and the anthracite coals of the west. Cwmbran sat on an area classified as 4012to 601 medium to very strong coking coals but as the workings moved westwards they hit pay-dirt by moving into the highly prized, and claimed to be the best in the World, type 301 prime coking coals. Even in the 1980’s Llanwern Steelworks claimed that they worked more efficiently with 301 type coals from the Celynen South Colliery than any other in the World.

In 1870 the mine was both owned and managed by John Lawrence. Interestingly, the Lists of Mines for 1858/60 claims that Cwmbran was owned by John Habakkuk. Although by 1878 the colliery was in the hands of the Patent Nut and Bolt Company and was still listed as working the Black Vein. In 1878 and 1888 the manager was J. Jacob.

On the 3rd of December 1883, the fireman, Joseph Williams, aged 59 years, was testing for gas when an explosion killed him outright. The inquest returned a verdict of accidental death. In February 1890, a terrible explosion of firedamp gas at the nearby Llanerch Colliery killed 176 men and boys. The immediate reaction was to strictly enforce the rules concerning the use of flame safety lamps as opposed to candles which gave off a much better light.

In 1896 Cwmbran employed 680 men underground and 118 men on the surface with the manager still being J. Jacob. In 1897 it was working the Meadow Vein (Yard/Seven-Feet) seam as well as the Black Vein (Nine-Feet) seam while the Fireclay (Viaduct) level worked the Meadow Vein as well as clay. Mr. Jacob was still the manager.

The Patent Nut and Bolt Company became Guest, Keen and Nettlefolds Limited after its formation in 1902 and increased the manpower to 840 men underground and 140 men on the surface in that year producing 260,875 tons of coal. The company employed 1,074 men underground and 144 men on the surface in 1908 when it was managed by W. Waplington, 1,218 men in 1909 and 1,483 men at Cwmbran Mine in 1913. The manager at that time was Thomas Welch.

In August 1914, Guest Keen, the owners, pledged to pay each wife ten shillings, with one shilling for each child per week if their husbands enlisted for the war, which may account for the drop in manpower between 1915 and 1916/19. In 1915 it employed 1,483 men and in 1916 it employed 1,150 men. In 1918 Thomas Welc(s)h was still the manager and the mine employed 884 men underground and 148 men on the surface. In 1919 Mr. Welsh was still the manager and the colliery employed 938 men.

GKN retained control of the colliery until its closure in 1927. At that time it, along with Henllys, employed 500 men and was still managed by Thomas Welc(s)h. GKN was a member of the Monmouthshire and South Wales Coal Owners Association.

In September 1928 the machinery at this colliery was dismantled and sold by auction for £205,940.00.

Based on the Nine-Feet seam this colliery’s coals were classed as type 501 High Volatile Coal, strong to medium caking, and used for coking blends.

From 1872 until its closure there were 46 fatalities at this colliery including two men killed under a fall of roof in 1893 and another two killed in the same circumstances in 1905.

Some of those who died at this mine:

- Apr 1848.Thomas Williams: Fall of a large stone.

- 18/04/1849 George Benjamin: Fall of stone from the roof.

- 9/08/1851 William Edwards: Fell under trams.

- 22/02/1854, Walter Emanuel: Explosion of firedamp at naked light.

- 16/11/1858 James Hudd: Fall of rubbish.

- 10/12/1863 James Miller, Age: 35: Collier: A fall of roof brought down some gas which he incautiously fired

- 7/06/1865, Thomas Morgan Age: 50: Collier: Had his back broken Nov 1864 and lingered until this day.

- 26/04/1866, Isaac Maynard, Age: 39: Mason, Robert Allen: There was a steam engine underground for the deep workings and the water for generating steam is so very bad that they frequently had to blow right through. For this, there was a large cock but it was unavoidably close to the main horse road. The haulier came out about 2.30 am but unfortunately either his horse ran away or he drove him too fast for on arriving at the boilers the trams flew off the plates and he knocked down the upright pipe to which the cock was attached and the escape of the steam became so rapid and fierce. Not one of the three men escaped. I have since had double cocks established so that there is but little possibility of any repetition. 3 killed.

- 15/04/1868 Thomas Williams, Age: 11: Doorboy: Fall of roof in the main road but he had no right to leave his door.

- 22/03/1869, Charles Powell, Age: 14: Haulier: Entanglement in the wheel of upper incline. 3/12/1870 Levi Slade, Age: 15: Haulier: Crushed by trams no one witnessed the accident and he was found dead.

- 30/03/1871, John Stephens, Age: 16: Haulier: A tram ran wild down the engine plane and killed him.

- 29/01/1874, William Byard, Age: 16: Haulier: Killed while running at the side of the horse.

- 13/05/1873, Isaac Phillips, Age: 19: Haulier: Killed by the crush of trams.

- 25/08/1876 Mark Isaac, Age: 73: Collier: Fall of the roof.

- 22/12/1876, Thomas Williams, Age: 38: Collier: Fall of stone

- 10/04/1880, William Pope, Age: 20: Collier: Fall of the roof.

- 9/02/1881 J. Westlake, Age: 26: Collier: He died of blood poisoning on the 8th. March, after having his leg amputated. It was broken by a piece of stone falling upon it while he was wedging down some coal.

- 3/12/1883, J. Williams, Age: 59: Fireman: Explosion of firedamp.

- 22/06/1885, Mathew King, Age: 58: Collier: Fall of fireclay.

- 9/11/1885 George Stephens, Age: 27: Labourer: Injured by a fall of stone and died on the 10th. He was wedging down some stone which was known to be sprung but it fell before he expected and injured him severely internally.

- 11/08/1886 William Griffiths, Age: 22: Haulier: When taking spraggs out of a train in a stall it ran back onto him and crushed him.

- 19/01/1887, David Williams, Age: 18: Collier. Fall of coal.

- 3/07/1888, David Thomas, Age: 55: Collier: Killed on No.1 South Level engine plane whilst going to work.

- 9/07/1889, John Jones, Age: 20: Repairer: An explosion of firedamp at a naked light

- 3/06/1890 William Berry, Age: 15: Collier boy: Fall of roof near the face from slips

- 18/12/1890, John Morgan, Age: 24: Collier: Fall of coal from the face of his working place,

- 13/01/1893, Thomas Morgan Age: 40: Timberman, Frederick Hamblin, Age: 14: Collier boy: Fall of roof. While engaged in replacing timbers on a roadway a fall occurred before they got the new ones properly tightened up lagged and weighted which discharged them on the deceased. As it occurred at the close of the shift and after the haulier had taken out the last tram the occurrence was unknown for 3 or 4 hours when in consequence of their not returning home search was made. The boy was still alive when his father and the examiner reached the place but died before they were able to release him. 2 killed.

- 2/09/1893, Thomas Powell, Age: 68: Haulier: On the surface. His horse apparently took fright and bolted with the trams to which it was hitched. In trying to stop the horse he was run over by the trams and killed.

- 4/05/1896 John Elliot, Age: 27: Coke filler: Crushed between buffers of railway trucks on the sidings whilst standing out of the way and not noticing what was going on.

- 10/03/1897 Samuel Male, Age: 24: Collier: Fatally run over and crushed on the endless chain haulage road, having stumbled and fallen in front of a loaded tram while attempting to put his mandrill on it.

- 24/05/1897 Thomas Cooke, Age: 25: Haulier: While hitching two trams together for a journey to take to the shaft he was crushed by a fall of coal from the face in a “Barry” working place.

- 5/01/1898 William Lewis, age: 32: Haulier: Fall of roof from a slip in a stall road up which he was taking some empty trams.

- 22/12/1899 Jacob Lowry, Age: 31: Top ripper: Fall of the roof near the coal face while knocking out props in front of the stall road in order to rip top for height.

- 24/05/1910, George Davies, Age: 61: Killed by runaway trams on endless rope haulage roads. 18/06/1910, Albert Mayo: Died from a strain.

- 20/01/1913, Albert Heath, Age: 17: Clip boy: He was run over on the surface by three full trams which were running down a slight gradient to the weighing machine. He died the following day. 3/04/1914 Moses Chamberlain, Age: 42: Haulier: Fall of the roof on a double parting

- 29/03/1915, William Lewis: Fell on a mandril.

- 21/02/1916, Albert Parfitt: Struck on the head by timber.

- 25/01/1917, Stanley Cole: Crushed by a tram.

- 2/01/1920, William Williams Trams ran wild.

- 19/01/1920, Eric Phillipson: Found lying under a tram.

- 21/02/1921, Leonard Robbins was struck by a lump of coal.

- 29/11/1922, Elijah Jones, Age: 54, Died from injuries received in an accident in the colliery yard.

- 31/03/1923, Richard Southwood: killed by a runaway tram.

- 9/04/1923, Thomas Smith: Fall of stone and debris.

- 11/10/1923, Norman Mundy, Age: Fall of the roof.

- 3/01/1924 George Wheatstone, Run over by coal trams.

- 2/08/1924, Charles Baker: Kicked by a horse.

- 1/05/1925, Henry Lawler: Roof fall.

- 7/02/1927 Charles Humphries: Run over by trams.

- 21/04/1927, W.H. Copper, Age: 41: Haulier: Fell between tram and side.

Some statistics:

- 1889: Output: 201,747 tons.

- 1894: Output: 263,874 tons.

- 1896: Manpower: 798. Output: 212,179 tons.

- 1897: Output: 224,342 tons.

- 1898: Output:128,378 tons (strike).

- 1899: Manpower: 794. Output: 241,831 tons.

- 1900: Manpower: 897. Output: 245,095 tons.

- 1901: Output: 257,624 tons.

- 1902: Manpower: 980. Output: 260,875 tons.

- 1903: Manpower: 989. Output: 260,875 tons.

- 1904: Output: 266,579 tons.

- 1905: Manpower: 1,014. Output: 258,592 tons.

- 1906: Output: 269,972 tons.

- 1907: Manpower: 1,293. Output: 263,731 tons.

- 1908: Manpower: 1,219. Output: 267,971 tons.

- 1909: Manpower: 1,218. Output: 277,255 tons.

- 1910: Manpower: 1,202. Output: 217,344 tons.

- 1911: Manpower: 1,230. Output: 251,121 tons.

- 1912: Output: 219,409 tons.

- 1913: Output: 256,911 tons.

- 1914: Output: 250,126 tons.

- 1915: Manpower: 1,483. Output: 176,613 tons.

- 1916: Manpower: 1,150. Output: 176,496 tons.

- 1917: Output: 169,196 tons.

- 1918: Manpower: 1,032. Output: 156,617 tons.

- 1919: Manpower: 938. Output: 163,912 tons.

- 1920: Manpower: 1,242. Output: 146,981 tons.

- 1923: Manpower: 1,201.

- 1924: Manpower: 1,130.

- 1925: Manpower: 1,175

- 1926: Manpower: 1,175

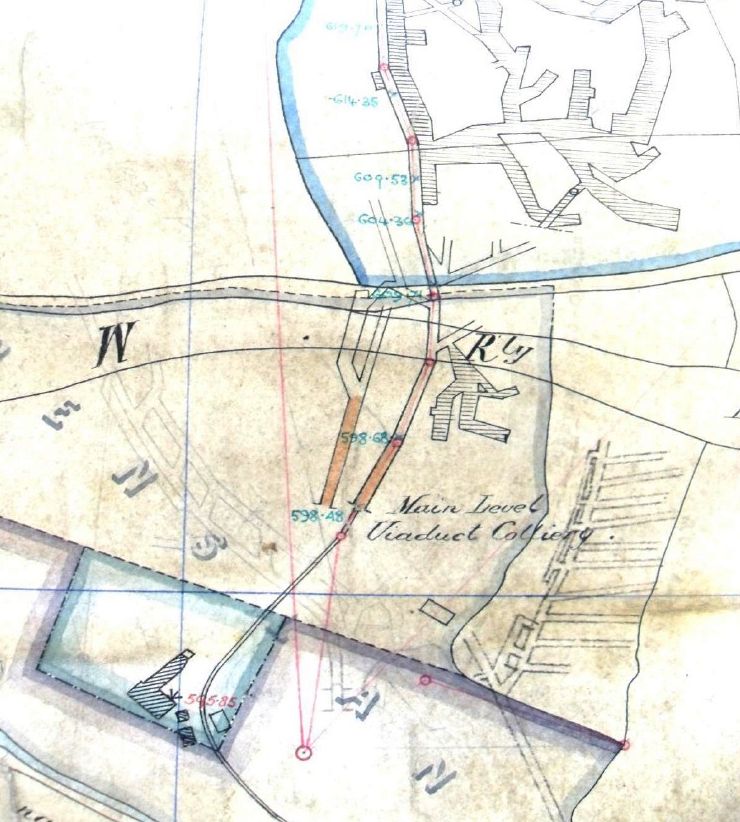

VIADUCT COLLIERY

Pontypool, Afan Lwyd Valley

Although this level was not in Cwmbran, but near Cwmnantddu, Pontypool it was an integral part of the works and collieries of GKN.

Although this level was not in Cwmbran, but near Cwmnantddu, Pontypool it was an integral part of the works and collieries of GKN.

This was a level that was worked in the early decades of the 20th century for coking, manufacturing and steam coals by Guest, Keen and Nettlefolds Limited (from 1903). In 1900 it was owned by the Viaduct Colliery Company c/o A.H. Bailey and employed only one man. In 1902 it employed 49 men working underground and 7 men working at the surface of the mine, in 1908 the figures were 59/10 and the manager was William Waplington. It employed 64 men in 1913, when the manager was W. Buck, in 1916 it employed 36 men, Mr. Buck was still there in 1918 when it employed 33 men, in 1919 when it employed 26 men and in 1920 when it employed 32 men. In 1927 Thomas Welsh was the manager and it employed 21 men.

In 1934 Guest, Keen and Nettlefolds Limited was based at London Works, Smethwick, Birmingham with the directors being; Sir John F Beale, T.S. Peacock, Samuel R Beale, Sir James Gomer Berry, Thomas J Callaghan, Lord Camrose, Lieutenant Colonel Christian H.C. Guest, James H Jolly, Howell R Jones, Sir David R Llewellyn, Thomas Z Lloyd, W.R. Lysaght, C. Keen and K.S. Peacock. In 1935 it was managed by W.T. Stead and employed 3 men working on the surface and 13 men working underground producing 7,000 tons of coal from the Meadow Vein (Yard/Seven-Feet) and Old Coal (Five-Feet/Gellideg) seams as well as fireclay. In 1938/40 it employed 24 men, in 1944 it employed 23 men and in 1945 it employed 20 men underground and 4 men on the surface producing mainly fireclay. The closure date was in 1953.

Nearby was the Elled Colliery which was a drift mine that worked the Elled seam under the ownership of the Patent Nut and Bolt Company. In 1888/1900 it was managed by J. Jacob. In 1900 there were no men listed as working in this mine. It worked between 1887 and 1900.

CWMBRAN BRICKWORKS COLLIERY

This mine was worked mainly for fireclay for the local brickworks and was owned in turn by John Lawrence, H. Parfitt and then Guest, Keen and Nettlefolds Limited in 1921. It was probably the same level as the Porthmawr No.2 (Clay ) Level that John Lawrence took control of in 1852, he closed it in 1865 but sub-leased it to H. Parfitt in 1867. It was still in Parfitt’s hands in 1878 when T. Davies managed it. In 1896 it employed 14 men underground and 1 man on the surface working the Meadow Vein seam and clay. From there on its history becomes vague until a Brickworks Level is recorded in 1921.

PORTHMAWR COLLIERY

Cwmbran

A small level was opened in 1837 to work both coal and clay for the local brickworks by R.J. Blewett. It was sold to John Lawrence in 1852 and merged into his Cwmbran Colliery. It was also known as Clay or No.2

LITTLE GREEN MEADOW COLLIERY

Cwmbran, Afan Lwyd Valley

This was a small level that was worked on the south-eastern extremity of the South Wales Coalfield. It was owned by T. Morgan in 1882/8 but it failed to find a workable seam.

HENLLYS COLLIERY

Henllys, Afan Lwyd Valley (25829444)

This was a level that was situated on the south-eastern extremity of the South Wales Coalfield two miles to the south of Cwmbran Colliery. It was the nearest mine to the Port of Newport in the Afon Lwyd Valley. It was driven into the outcrop of the Black Vein (Nine-Feet) seam which was locally called the Rock Vein. This seam dipped at 55 degrees for the first 200 yards, then dipped at 34 degrees for the next 500 yards but then eased off to between 22 to 12 degrees dip. Joshua Hanson opened both the mine and a brickworks down the valley at Ty Coch in about 1814 and it stayed with the Hanson through Hanson & Company (1860/65), and in 1870 with Hanson & Cyrus. The lists of mines in 1878 show that it was owned by Hill and Company owners of the Oakfield Wire Works. It was managed in 1878 and 1888 by E.S. Jones.

In 1889 it produced 13,657 tons of coal and in 1894 it produced 30,000 tons of coal being owned in both years by the Patent Nut and Bolt Company. In 1896 it was still owned by the Patent Nut and Bolt Company who employed 51 men underground and 16 men on the surface working the Black Vein and clay. In 1899 it employed 9 men and was listed as abandoned. In 1901 it employed 7 men underground and 3 men at the surface. In 1911 it employed 139 men. Guest, Keen and Nettlefolds (GKN) Limited absorbed it into Cwmbran Colliery.

The incline haulage plane for this colliery started by the canal at the bottom of the valley and rose westwards for about two miles and 600 feet in height. Around the mouth of the drift, there was another entrance, for the water drainage adit, some cottages, a limekiln and three quarries and two reservoirs. About 800 to the north of the main drivage was the upcast ventilation shaft, it was 370 feet deep and fifteen feet in diameter and appears to have been sunk to improve ventilation for both the Henllys and Cwmbran Mines when the Patent Nut & Bolt Company owned it.

A watercourse drivage was driven under the mountain to near Cwmcarn Colliery from the Henllys part of the Cwmbran Colliery workings. The entrance can still be seen alongside the road a few hundred yards inside the entrance to the Forest Drive.

A watercourse drivage was driven under the mountain to near Cwmcarn Colliery from the Henllys part of the Cwmbran Colliery workings. The entrance can still be seen alongside the road a few hundred yards inside the entrance to the Forest Drive.

It worked the Black Vein (Nine-Feet), Elled (Two-Feet-Nine), Meadow (Yard/Seven-Feet), Old Coal (Five-Feet/Gellideg) and Red seams. It was abandoned in July 1928. The Henllys pit was filled with weathered shale in June 1970.

Five miners died in various accidents at this colliery, but just as sad was the incident on the 8th of December 1883 when an unknown man, aged around 30 years was killed on the incline to the colliery by trams. No one could identify him and he was buried unnamed.

Some of those who died at this mine;

- 10/01/1887 John Lewis, Age: 26: Collier: Fall of coal at the face.

- 31/12/1887, Charles Blackwell. Age: 19: Collier: Fall of coal from the face

- 1/11/1889, Edward Cooper, Age: 19: Collier: Fall of coal at the face.

SOME OF THE OWNERS

The Patent Nut and Bolt Co

This company was established in 1853 with its Victoria Works at Smethwick. Around 1856 an American, Francis Watkins along with Arthur Keen owned the company, which, in 1860, following a fire at their Victoria Works, moved to the London Works at Birmingham. This works came to dominate the fastening industry and became one of the largest of its kind in the world employing 500 people. It was a trailblazer in machine production and this meant that all its products were fairly uniform and could be used to a set pattern.

The success of the company led it to become a joint stock company in 1864, the same year that it moved to South Wales. By 1869 they listed their works as at; London Works, Birmingham; Stour Valley Works, West Bromwich; and Cwmbran Works, Newport, South Wales. In 1900 Arthur Keen, the chairman of the company, brought about the merger with the Dowlais Iron Company and Guest & Co., to form Guest, Keen & Co.

Dowlais Iron Works

This was the first furnace in the Merthyr Tydfil area when it was opened in 1759 by Thomas Lewis and Partners on the estate of Lord Windsor. In 1782 John Guest became a partner, he was followed in 1787 by his son, Thomas Guest and from an annual output of iron of 1,500 tons in 1785 the Works developed to fifteen furnaces and 2,000 tons of iron weekly by 1810. One of the main reasons for this rapid expansion was the vast reserves of coal and iron ore which enabled them to lease the surplus to the Penydarren Works.

The grandson of John Guest, John Josiah Guest now came to the fore in the running of the Works, and following the death of his bride of only nine months totally dedicated himself to this task. By 1823 he was so rich that he opened a private bank with branches in Cardiff and Merthyr Tydfil. In 1845 the Company employed 7,000 workers with an annual wage bill of £250,000. Annual output stood at 140,000 tons of coal and 70,000 tons of iron, the largest production in the world. The original lease of £26 per annum expired in 1847 and the then owner of the land, the Marquis of Bute, re-negotiated the terms to a more favourable output related scheme which averaged a payment of £30,000 per annum.

The Dowlais Iron Works was the first to use the new Bessemer process for converting iron to steel but even this could not disguise the realities of the marketplace and in 1887 a decision was made to open a new works on the coast at Cardiff and close down the Dowlais operations. However, even steel masters can be sentimental sometimes, and it was eventually decided to leave rail rolling at Dowlais

Josiah John Guest was born at Dowlais on the 2nd of February 1785, nine months before the death of his grandfather. He was educated at Bridgnorth and Monmouth grammar schools. He threw himself into the family business with vigour and developed it into the largest and most productive in the world. J. J. Guest, in addition to being the manager of this huge concern, also improved his position as a partner in the company — holding one-sixteenth at his father’s death, he obtained eight-sixteenths more on the death of his uncle William Taitt in 1815. By 1849 he had become sole proprietor. Guest sat as a member of Parliament for Honiton from 1825 until 1831. He was returned unopposed in 1832 (as a Liberal and Free Trader) as the first M.P. for the Merthyr borough and kept his seat until his death in 1852.

In 1838 he was created a baronet. During the later years of his life he lived at Canford Manor, Dorset, where his descendants have since lived, but as death approached he returned to Dowlais, the home of his birth, youth, and activities, and there he died on the 26th of November 1852 (taken from Welsh Biographies Online) John Josiah’s son, Ivor Guest wasn’t that interested in the works and sold it to Arthur Keen in 1899 as Guest, Keen & Co. Keen was pretty keen on expanding the business and in 1902 bought Nettlefolds Limited and with the Patent Nut & Bolt Company, formed the new, and lasting up to today, Guest, Keen & Nettlefolds Limited.

John Sutton Nettlefold (1792 to 1866) started his working life by opening a hardware store in London in 1823, in 1826 he added to this his Sunbury on Thames workshop which manufactures wood screws. Not content with that, he moved to the midlands of England and opened a factory in Birmingham. To raise money for a new factory he went into partnership with his brother-in-law, Joseph Chamberlain the father of the future prime minister of the same name. They opened a factory at Smethwick but left the running of the business to the sons; John Henry Nettlefold and Joseph Chamberlain. However, the Nettlefolds later became sole controllers with Frederick and Joseph Nettlefold in charge.

Sir DAVID RICHARD LLEWELLYN AND WELSH ASSOCIATED COLLIERIES LIMITED.

He was born in 1879 at Aberdare, the son of the general manager of the Bwllfa and Merthyr Dare Collieries. He was educated at Aberdare and Llandovery College before following a course in mining engineering at University College, Cardiff ( 1901-03 ). He went to the USA for 2 years to gain more experience and on his return he began to acquire local pits and then more widely in south Wales, pioneering the use of new coal-cutting machines which he had seen in America. In 1916, as chairman of the Gwauncaegurwen Coal Company, and the Cambrian Combine.

He became a director of many enterprises in the coal trade, especially the Vale of Neath, Amalgamated Anthracite Collieries, Guest, Keen & Nettlefold, and chairman of the Welsh Associated Collieries and later vice-chairman of the United Powell Duffryn Associated Collieries (under the chairmanship of Edmund Hann ). By about 1920 it could be claimed that he owned or managed about 1/7 of the South Wales coalfield (including Cwmbran and Henllys). He played an important part in the development of management methods in the coal industry and the growth of amalgamated companies. He was an influential figure in the Coal Owners Association (especially about 1925-30) and he was acknowledged as a leader with moderate views. Both he and his brother W.M. Llewellyn mixed with their workers and they retained their personal and local links.

While his home was in Aberdare (Goytre, Llewellyn St., then Fairfield House) he was an active member of the Town Council ( chairman 1920 ), High Constable of Miskin and a prominent Liberal and Unitarian (at Hen-dy-cwrdd, Aberdare ). He was treasurer of University College, Cardiff 1922, and president 1924. The baronetcy was created in 1922 and he was awarded a hon. LL.D. by the University of Wales in 1929. He moved to The Court, St. Fagans. His chief hobbies were hunting (both he and his brother were masters of the Bwllfa hunt) and horses. He married Magdalene (daughter of Henry Harries, ‘ Afonwy’, Baptist minister of Treherbert ) in 1905 and they had 4 sons and 4 daughters. He died at his brother’s house, Tynewydd, Hirwaun, Glam., on the 15th of December 1940.

In January 1930, the coal mining interests of Guest, Keen and Nettlefolds Limited and Llewellyn’s many companies were merged into Welsh Associated Collieries Limited. This new company controlled around 25% of the South Wales steam coal trade, running sixty mines, and producing nine million tons of coal a year. It was estimated that they had 800 million tons of coal reserves. In exchange for setting up the new company, GKN held stock of up to £2,000,000 in value in it, with a total valuation being £8,890,000. D. R. was chairman of the new company and his brother, W.M. managed the mines.

This information was supplied by Ray Lawrence and is used here with his permission.

Return to previous page