Near Pontypool, Afan Lwyd Valley

(SO 2443 0204)

Although records show that in 1888 Partridge, Jones and Company were working a level called Blaensychan in the Tillery (Brithdir) seam with the manager being J. Morgan, the upcast shaft for the pit wasn’t sunk until 1890, with the Llanerch Colliery used as the downcast shaft for the new colliery which was just across the valley from it.

Blaenserchan was originally sunk to the Five-Feet/Gellideg seam and was elliptical in shape, 16 ft by 11ft, but in 1899 it was deepened to 350 yards and the rest of the shaft was round and 18 feet in diameter. The No.1 Pit steam winding engine was built at Uskside Engineering Works and had a winding capacity in 1950 of 16 men.

A second shaft (the downcast) was sunk in 1915/6 to a depth of 363 yards with this shaft being 20 feet in diameter. This was the main coal winding shaft and could carry two trams of coal per wind and give a winding rate of 700 tons per shift. The steam winding engine was a Worsely Mesnes type.

During the sinking of this No.2 Pit the Brithdir seam was struck at a depth of 116 yards, the Four-Feet seam at 287 yards, the Nine-Feet seam at a depth of 319 yards, and the Five-Feet/Gellideg seam at a depth of 363 yards. In all, they found a total thickness of coal of 52 feet of which 42 feet was in seams over two feet thick. The Tillery seam in this area is 30 inches thick. The Garw seam is 32 inches thick, the Upper-Six-Feet seam, 71 inches thick, and the Lower-Six Feet seam, 30 inches thick. The Upper and Lower Four-Feet seams were generally washed out. Generally, the colliery’s coals were classed as type 301B Prime Coking Coals.

In 1896 this pit employed 398 men underground and 38 men on the surface with the manager being J. Morgan. It was only working the Brithdir seam. In 1908 the manager was J. Morgan and the pit employed (with Llanerch) 1,738 men underground and 225 men on the surface. In 1913 this colliery employed 1,079 men with the manager being W. Llewellyn, with the same manager it employed 1,785 men underground and 275 men on the surface in 1918 (with Llanerch). Mr. Llewellyn was still the manager in 1927.

Pontypool magistrates fined the manager and under-manager of Blaenserchan Colliery £2 each in November 1932, for not providing refuge holes along the east level in the Elled seam. A refuge hole was a place that a man could shelter in when a journey of trams passed by.

In 1935 the colliery employed 683 men underground and 122 men on the surface, the manager now being F. Wilcox. Mr. Wilcox was still manager in 1938 when it employed 713 men underground and 133 on the surface. In 1943 it was managed by PSH Jones who employed 578 men working underground in the Meadow Vein, Three-quarter, Old Coal, Black Vein, Elled and Big Veins and 142 men working at the surface of the mine.

On Nationalisation in 1947 it employed 474 men underground and 116 men on the surface producing coal from the Meadow Vein (Yard/Seven-Feet), Old Coal (Five-Feet/Gellideg), Black Vein (Nine-Feet), Elled (Two-Feet-Nine), and Four-Feet seams. The manager was now P.S.H. Jones. The colliery had its own coal preparation plant and coal selling depot. Mr. Jones was still the manager in 1949.

In 1950 the colliery was working the Big Vein on the old heading and stall system, and the Three-Quarter and Old Coal seams by fully mechanised longwall coalfaces. At that time the NCB stated that Blaenserchan Colliery had coal reserves that amounted to 16,000,000 tons, 7.5 million of which was in the Old Coal seam, the Garw seam at that time was not included.

In 1956 out of a total manpower of 628 men, 261 of them worked at the coalfaces, the coalface figure dropped to 244 men by 1961 and the total figure dropped to 520 men. This was also a time of mechanization at the coalfaces and the subsequent breaking of output records; in 1956 the daily output record was 1,107 tons, this was shattered in July 1958 to 1,249 tons, while the annual output record of 197,062 tons set in 1952 rose to 214,911 tons in 1958.

In 1959 when compulsory retirement for the over 65’s was implemented there were 25 men over that age working at this pit.

In 1961 was grouped with Big Pit-Garn-Kays, and Beynons, the Group employing 2,579 men and producing 527,500 tons of coal.

The Times newspaper on the 4/11/1965 reported:

As a result of increased productivity two Monmouthshire collieries, facing closures, have been saved, a divisional board spokesman said last night. The collieries –Beynon Colliery and Blaensychan Colliery, in north Monmouthshire – were no longer regarded as short-term pits and were now expected to operate for several years.

On the 2nd of October 1972 two colliers were killed under a roof fall in the T1 District of the Three-Quarter seam, then on the following day, Tuesday the Third of October one collier died under a fall of roof in the O10 District.

Blaenserchan was now struggling to find workable coal reserves, the majority of the best coal reserves had been worked. They opened up coalfaces in the Black Vein seam in the mid-1960s and worked three panels called BL1, BL2 & BL3, they never achieved the expected output figures due to the geological conditions, which were mainly caused by disturbances created by workings in the Six-Feet seam, which was just above the Black Vein and the last one closed in March 1968. The Three-Quarter or Six-Feet, and the Big or Four-Feet seams were then tried with disappointing results, again three faces were opened, B1, B2 & B3, but didn’t last long due to very bad conditions, and the last one closed in February 1972. The one coalface in the Three-quarter seam, the T1, closed in 1976. They also worked the Five-Feet/Gellideg (Old Coal) seam, but this seam had a soft roof and wet conditions, plus a high dirt content. Matters were looking pretty ropey for the pit until the manager, Glyn Payne, probed the bottom seam of them all, the very thin Garw, they found that it was just about workable at around two feet nine inches thick.

In 1974 the NCB reported that a major investment program was required to produce the projected output of coking coals for the 1980s and to ensure the continuity of supplies into the 1990s. In 1974 exploratory boring at Blaenserchan Colliery proved that the Garw seam was 2 feet 9 inches to 3 feet thick over a large area that previously was thought to be too thin to work. The total reserves proved in this seam were 3.5 million tons, which equals the remaining reserves of the seam at Abertillery.

Blaenserchan’s output was diverted by underground roadway to the Hafodyrynys New Mine, in 1977 at a cost of £3 million. This link-up saved the annual £28,000 cost of running four locomotives on a seven-mile surface railway and the reduction in surface manpower had the effect of increasing the output per man shift from 13 cwts in 1961 to 42 cwts in 1968. Blaenserchan’s coal was again diverted by underground roadway to Abertillery New Mine which was 3.5 miles away to the northwest and in 1985 to Marine Colliery.

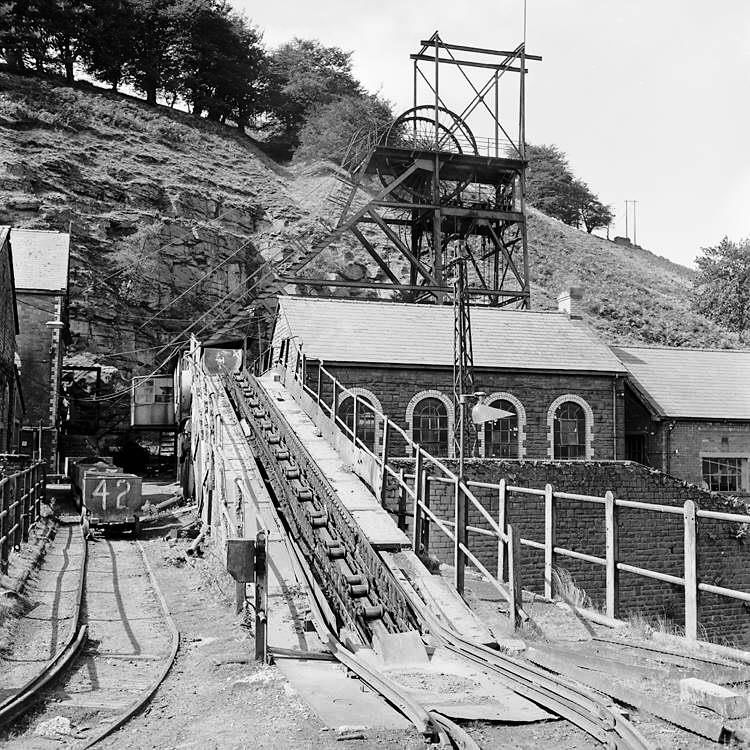

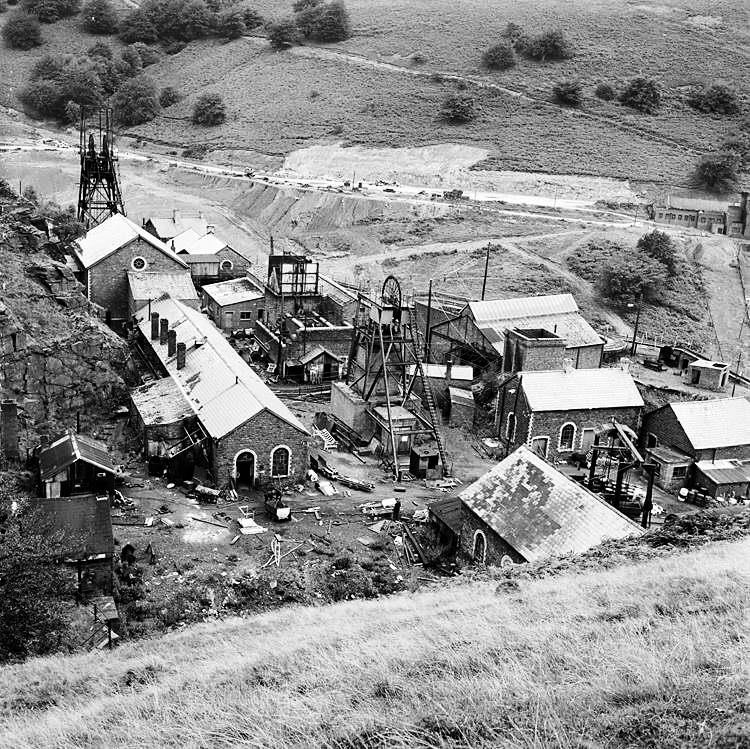

Blaenserchan Colliery 1975

With the closure of Cwmtillery Colliery in 1980 Blaenserchan had to bear the total cost of transporting its coal underground to Roseheyworth which averaged around £250,000 per annum. The system consisted of 7,000 metres of conveyors using 10 different conveyor belts. It was then decided to link Blaenserchan with Six Bells Colliery and via that colliery direct the coal to Marine Colliery. This link consisted of a 1,750 metre driveage from Six Bell’s No.5 Pit bottom on the Meadow Vein level and then dipping down 1 in 6 for 150 metres into Blaenserchan’s Garw seam workings.

By 1981 all of the thicker seams had been exhausted and the pit was working the Garw seam at an average section of only 32 inches and at a depth of 1,400 feet, coalface length was between 165 and 220 metres with coal cutting by Gleithobel ploughs and coalface roof supports being post and bars. Coalface output per man shift was planned at 4.8 tonnes, and overall output per man shift at 1.62 tonnes. The saleable yield of coal was 75% of the total output.

Manpower deployment was; development 42, coalface 136, others underground 169, and surface 56 men. In February of 1981, the G4 coalface had 210 metres to travel before hitting a faultline, if this could be traversed it would have another 750 metres. Daily advance on two shifts was 1.37 metres. The G7 was calculated to advance at a rate of 2.13 metres per day on double coaling shifts and had a life of 694 metres. Both the G4 and G7 coalfaces were expected to thin down to 28 inches thickness. The manager at that time Mr. B. Williams was concerned that when the South Garw workings at Abertillery New Mine stopped he would have to provide extra manpower for conveying the coal by means of using coal-face workers, which he estimated would reduce the OMS to 1.66 tonnes.

Due to the side of the valley on which Blaenserchan was sunk being so steep, the pithead baths were built on the other side of the narrow valley, and a train, and then a bus were used to ferry the men between the two.

In 1977 the NUM Lodge Secretary was George Smith while in 1981 to closure it was John Marshall. In 1969/75 the colliery manager was G.R. Payne while in 1976/9 it was T. Thomas and in 1980 it was B. Williams.

In 1983 this colliery was losing £13.60 on every tonne of coal that was produced and had a manpower of 421 men.

Following the return to work after the 1984 miners’ strike, Six Bells/Blaenserchan, achieved 73% of normal production despite some mechanical and electrical problems at Blaenserchan within one month of starting. But it was to no avail and Blaenserchan Colliery, the last deep mine to have worked in the Afan Lwyd Valley, closed on the 28th of August 1985.

The last faces to be worked in the Blaenserchan ‘take’ were the G8 and G9, but they were worked from the Six Bells Colliery and closed in February 1987.

From the sinking to nationalisation, there were 34 fatalities at this colliery. Eighteen of them were through falls of the roof and seven were through haulage accidents. These are some of them:

Some of those who died at this mine:

- 9/02/1882, John Payne, Age: 23, Haulier: Killed by descending cage when attempting to cross the bottom of the pit

- 12/11/1884, George Morgan, Age: 24, Collier: Explosion of gunpowder. He had put five inches of stemming on the powder and was hammering the pricker through it when the charge exploded, and he was killed on the spot.

- 16/02/1887, John Rudge, Age: 34, Collier: Fall of stone. He and another man were preparing to blast off some stone on the side of a heading when it suddenly fell owing to two slips which ran together at the back and which were previously invisible.

- 24/09/1889, Francis Reed, Age: 62, Collier: On knocking out a prop in the stall road to get the roof down, it fell unexpectedly before he could get away.

- 10/04/1890, George Smith, Age: 13, Doorboy: An underground engine started on the previous day exhausted into a small cistern or reservoir of water on the side of the road along which he and another boy of about the same age were making their way in the dark having lost their lights. The cistern had not been covered over and they fell into it and were scalded from the effects of which he died on the 26th.

- 24/09/1891, Henry Edwards, Age: 49, Shunter: As he was engaged in lowering a railway truck to the screens for loading he went to use the brake handle which was on the pit bank or retaining wall side and where there was no proper space for a man to stand between the truck and the pit bank. While putting on the break he appears to have slipped and fallen he was crushed against the retaining wall and thrown in front of the trucks and was then run over

- 13/04/1911, John Pugh, Age: 42, Haulier: While lifting one of two trams onto rails on a slight gradient the coupling bar between the trams was displaced and one of them moved and crushed him

- 21/03/1916, Frederick Hyde was knocked down by trams.

- 19/12/1917, William Stephens was run over by trams.

- 18/04/1918, Robert Connop was struck by falling timber.

- 1/12/1919, Clifford Jayne: Fall of stone.

- 25/03/1927, Thomas Burchild, Age: 47, Haulier. Putting a tram on the road when the pony backed knocked him down and dragged him a few yards. Died 25th Apr. 1928.

Some Statistics:

- 1889: Output: 78,071 tons.

- 1894: Output: 67,421 tons.

- 1899: Manpower: 302.

- 1900: Manpower: 489.

- 1902: Manpower: 1,378.

- 1910: Manpower: 1,030.

- 1912: Manpower: 1,091.

- 1913: Manpower: 1,070.

- 1918: Manpower: 2,060. (with Llanerch)

- 1920: Manpower: 932.

- 1923: Manpower: 1,043.

- 1924: Manpower: 1,056.

- 1925: Manpower: 1,105.

- 1926: Manpower: 1,141.

- 1927: Manpower: 975.

- 1928: Manpower: 942.

- 1929: Manpower: 983.

- 1930: Manpower: 1,043.

- 1932: Manpower: 992.

- 1933: Manpower: 838.

- 1934: Manpower: 846.

- 1937: Manpower: 806.

- 1938: Manpower: 846.

- 1940: Manpower: 1,043.

- 1947: Manpower: 590.

- 1948: Manpower: 682. Output: 175,000 tons

- 1949: Manpower: 790. Output: 182,000 tons.

- 1950: Manpower: 790.

- 1953: Manpower: 715. Output: 163,000 tons.

- 1955: Manpower: 628. Output: 118,744 tons

- 1956: Manpower: 613. Output: 125,626 tons.

- 1957: Manpower: 661. Output: 132,968 tons.

- 1958: Manpower: 637. Output: 130,415 tons.

- 1960: Manpower: 545. Output: 123,500 tons.

- 1961: Manpower: 520. Output: 104,708 tons.

- 1962: Manpower: 528.

- 1964: Manpower: 790. Output: 182,000 tons.

- 1969: Manpower: 445.

- 1970: Manpower: 425.

- 1971: Manpower: 490.

- 1972: Manpower: 475.

- 1978: Manpower: 369. Output: 68,168 tons.

- 1979: Manpower: 411. Output: 73,000 tons.

- 1980: Manpower: 427. Output: 72,922 tons.

- 1981: Manpower: 376.

- 1985: Manpower: 424.

Information supplied by Ray Lawrence and used here with his permission.

Return to previous page