Pengam, Rhymney Valley (NGR 15639745)

This pit was sunk by the Rhymney Iron Company to the Brithdir seam at a cost of £93,546.

This pit was sunk by the Rhymney Iron Company to the Brithdir seam at a cost of £93,546.

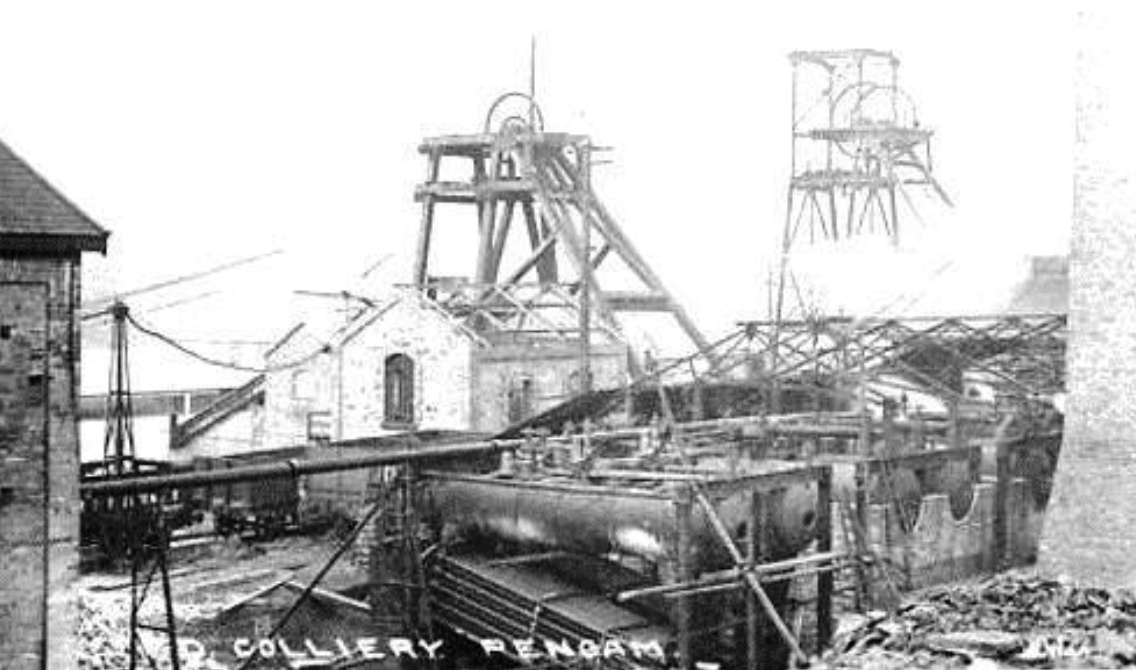

The shafts (No.1 North Pit and No.2 South Pit) were 17 feet in diameter and sunk to a depth of 312 yards. The headgear was 45 feet high. The coal winding shaft had a steam-driven twin-compound Robey Corliss engine with 23-inch and 37-inch diameter cylinders and a 42-inch stroke. All the other surface plant was electrically driven with two 600KW generators on site.

The sinkings were beset by excessive water problems; and when they had reached a depth of 61 yards in the North Pit and 55 yards in the South Pit by the 17thof June 1904, the winding engines had been installed along with the boilers when the sinkers went on strike over pay, they resumed work on the 12thof August 1904. The first coal was raised on the 16thof February 1906, but things didn’t go smoothly at this colliery in the early years; a mechanical breakdown on the electrical generator shut the pit for a month in February 1908, while in June of that year, the pit was shut for four months due to an inrush of water. In January 1912 extra pumps had to be installed but even these failed to stop another inrush of water on the 26th of June 1912 flooding a development district.

The underground workings were ventilated by a Capell fan, with the pumping of water out of the mine done by two 350hp electric motors each capable of shifting 40,000 gallons an hour. Hauling the coal out and the supplies into the coalface was done by a 150hp main and tail haulage with smaller haulages nearer to the coalface. It worked the Brithdir seam at an average section of 56 inches, but they soon encountered wetter conditions than anticipated and had to upgrade the pumping engine to 750hp On the surface of the mine were 100 coke ovens capable of producing over 1,000 tons of coke per week, and a coal washing plant capable of washing 60 tons of coal an hour.

In 1908 it employed 145 men underground and 51 men on the surface with William J Bowen as manager. The output of coal at that time was 600 tons a day, but this was expected to increase to over 1,000 tons a day in the near future. In 1913 Pengam was managed by H.E. Thomas and employed 375 men. At that time the Rhymney Company advertised as:

“Rhymney Iron Co. Ltd Established 1836 Sole Proprietors of the ‘Rhymney Merthyr’ Smokeless Steam Coal On the Admiralty List of Welsh Steam Coal for H.M. Ships at Ports abroad Used by the Principal Mail Steamship Companies and the chief British and Foreign Railways Also sole proprietors of Brithdir Bituminous Bunker Coal and Smith’s Coal as supplied to the Admiralty. Manufacturers and Shippers of -Coke -Made From Washed Coal. Washed Nuts & Pea-Nut Coal Shipping Ports: Cardiff, Penarth & Barry”

The Rhymney Iron Co was founded by some Bristol merchants trading as the Union Co to exploit a seam of iron ore found at the top of the valley. In 1803 Richard Crawshay purchased the Rhymney iron works and, as a wedding present, made his son-in-law Benjamin Hall (1777-1817) a partner c.1817 Mr. Hall sold the works and collieries of Rhymney to Mr. Crawshay Bailey for the sum of £73,000 but for some reason the deal was never completed[1]. William Crawshay of London may have been involved later. 1826 Sold to a joint stock company formed by William Forman and in 1836 The company was established. The company was registered on 24 March 1871 and operated until acquired by Powell Duffryn in 1921 and run as a subsidiary,

In 1915/6 Pengam employed 558 men with E. Merriot as the manager. In 1918 it employed 518 men with J. Davies as the manager and in 1919 it employed 519 men with the same manager. On the 5th of September 1921, the pit was closed down only to be restarted on the 5th of March 1923 under the ownership of Powell Duffryn. In 1921 the Rhymney Iron Company came under the control of the Powell Duffryn Steam Coal Company Limited who employed T.B. Fisher as manager. It was closed again on the 15th of August 1925 when 600 men were thrown out of work. It restarted in 1926. It employed 300 men in 1927 and J.J. Hughes as manager in 1934 and in 1938 when it employed 67 men. In 1943/5 Mr. Hughes was still the manager. This Company retained control of Pengam Colliery until Nationalisation in 1947.

In 1947 this pit was the most productive colliery in the Coalfield with an output per man shift of 48 cwts (2.4 tons), and on top of this, two colliers, Leonard Denham, aged 23 years, of Cefn Fforest and Melville Jones, aged 35 years of Fleur-de-Llys, smashed all South Wales coal filling records by filling, straight into trams at the coalface, 71 tons 8 cwts between them in five hours on a Friday Night in December. Leonard had filled 34 tons and 15cwts, while Melville filled 36 tons and 13 cwt. Leonard could be excused for slacking a little bit. He had already worked the morning shift and for that day had filled almost 45 tons.

They also claimed that if the floor of the coal seam had been better they would have filled another 20 tons. That was enough for Melville who when interviewed by the Western Mail stated “no more record-breaking” but super-collier Leonard Denham would “have another go if conditions were right.”

The colliery employed 390 men in 1951 and produced 76,254 tons of coal, 82,000 tons of coal in 1954, and 77,401 tons of coal with 274 men in 1955, with 133 of them being employed at the coalface.

In 1955, the output for each miner for the year was a respectable 282.48 tons, which was way above Penallta Colliery at 239.64 tons and in between the two other local pits, Bargoed and Britannia. Bargoed doing 253.63 tons and Britannia 341.83 tons per man per year. Different to the deeper mines which had up to nine good seams to work, Pengam only had one, the Brithdir and when this became exhausted closure followed.

Pengam Colliery was closed on the 29th of June 1956. The underground pumping station was kept open to protect Britannia Colliery from flooding with access to the Pengam pumps via a landing in the Britannia shafts.

- 11/09/1911, Robert Thomas, aged 55 and a collier was buried under a roof fall.

- 28/06/1912, William J. Davies, Age: 31 and a haulier, was crushed by trams.

- 23/09/1913, Thomas Boulton, aged 44 and a collier. He was buried under a fall of coal and stone. 6/12/1928. William Knight, aged 21 and a collier, Fall of stone.

- 19/9/1927, B.J. Phillips, a collier at this mine was killed under a roof fall.

- 1/05/1929, Lewis Ford, aged 34 and a haulier, he was replacing a derailed tram when the horse bucked and he was caught between the buffers.

- 19/11/1929, Rees Thomas, aged 58, and a haulier, was buried under a fall of stones, the trams jumped off the rails and knocked out a post.

- 5/12/1929, James Saddler, aged 51 and a collier, Fall of stone.

Some statistics:

- 1904: Manpower: 127.

- 1905: Manpower: 112.

- 1906: Manpower: 57.

- 1907: Manpower: 170.

- 1908: Manpower: 196.

- 1909: Manpower: 249.

- 1910: Manpower: 328.

- 1911: Manpower: 375.

- 1912: Manpower: 440.

- 1913: Manpower: 530.

- 1914: Manpower: 570

- 1915: Manpower: 474.

- 1916: Manpower: 503.

- 1917: Manpower: 534.

- 1918: Manpower: 518.

- 1919: Manpower: 666.

- 1920: Manpower: 671.

- 1921: Manpower: 503.

- 1922: Manpower: 12.

- 1923: Manpower: 460.

- 1924: Manpower: 496.

- 1925: Manpower: 483.

- 1926: Manpower: 204.

- 1927: Manpower: 317.

- 1928: Manpower: 313.

- 1929: Manpower: 330.

- 1930: Manpower: 334.

- 1931: Manpower: 343.

- 1932: Manpower: 342.

- 1933: Manpower: 27.

- 1934: Manpower: 23.

- 1935: Manpower: 23.

- 1936: Manpower: 88.

- 1937: Manpower: 222.

- 1938: Manpower: 67.

- 1939: Manpower: 190.

- 1940: Manpower: 200.

- 1941: Manpower: 195.

- 1942: Manpower: 207.

- 1943: Manpower: 201.

- 1944: Manpower: 205.

- 1945: Manpower: 195.

- 1946: Manpower: 198.

- 1947: Manpower: 281.

- 1948: Manpower: 328.

- 1949: Manpower: 276.

- 1950: Manpower: 398.

- 1951: Manpower: 398.

- 1952: Manpower: 398.

- 1953: Manpower: 327.

- 1954: Manpower: 303.

- 1955: Manpower: 281.

Information supplied by Ray Lawrence and used here with his permission.

Return to previous page