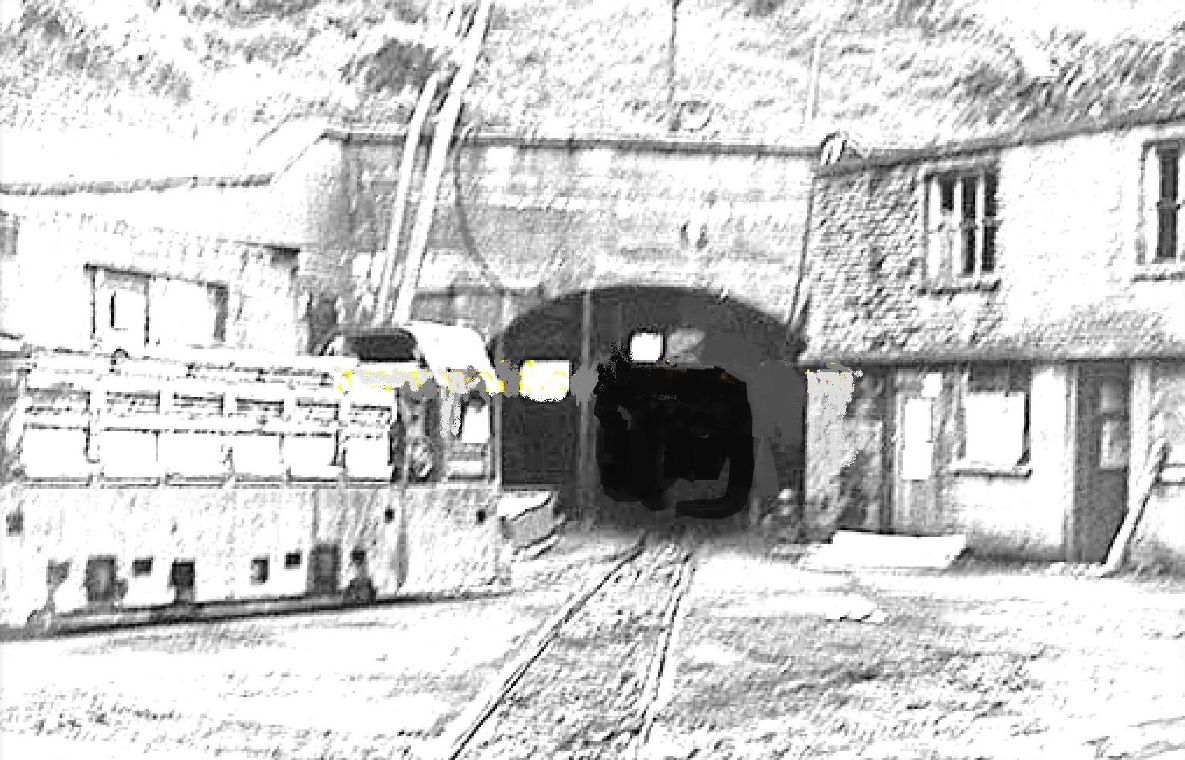

Old Mine

Pontypool – Old Mine: SO 2677 0008 Link to map

Pontypool – New Mine: ST 2426 9893 Link to map

Glyntillery Colliery was a level; levels, adits or drifts, are methods used to access coal seams that are near or at the surface, which is called the outcrop. Levels are driven into the side of a hill or mountain and are often used when the coal body is located inside the mountain but above the adjacent valley floor. In cases where the coal seam outcrops at the surface, the level, adit or drift may follow the vein until it is worked out; in this case, the level is rarely straight. The use of levels for the extraction of coal is generally called drift mining.

The ground is secured by timbering or with the main roadways by arching or brickwork. Levels that are driven across the stratification, or generally anywhere not in coal, are known as stone or cross measure drifts.

Access to a mine by a level has many advantages over vertical access shafts as used at the old Hafodyrynys Colliery. Less energy is required to transport miners and supplies into and out of the mine. It is also much easier to bring coal out of the mine.

In combination with shafts, levels form an important element in ventilating the workings. In simple terms, cool air will enter through the mouth of the level, be warmed by the higher temperature underground and will naturally exhaust from the return level or an air shaft, some of which are sunk specifically for this purpose and are known as ventilation shafts.

Most drainage adits are designed to slope slightly upwards from the entrance so that water will flow freely out of the mine. Mines that have adits can be at least partly drained of water by gravity alone or power-assisted gravity. The depth to which a mine can be drained by gravity alone is defined by the deepest open adit which is known as the “drainage adit”. Workings above this level (known as “above adit”) will remain unflooded as long as the adit does not become blocked. All mine workings below both the drainage adit (“below adit”) and the water table will flood unless pumps are installed for drainage. Until the invention of the steam engine, this was the main restriction on deep mining. Of course, adits are still useful for deeper mines because the water only needs to be raised to the drainage adit rather than to the surface.

This mine was driven to work the Brithdir coal seam of the Upper Coal Measures (Lower Pennant Measures) which is near the surface in this area. It was also called the Red Ash in the Ebbw Vale area, the Tillery in the Abertillery area, and the Pontygwaith in the Tredegar area. This seam was extensively worked to the east of the Torfaen County Borough particularly at Tirpentwys, Glyntillery, Quarry, Cwm Glyn and Plas-y-coed collieries. The section of this seam at Blaentillery drift was coal 9 inches, clod 27 inches, coal 24 inches, while at Blaenserchan colliery it was one coal with a section of 27 inches. It further deteriorates towards the south and north.

This mine is claimed by the NCB to have been opened in 1889 (the Glyntillery Colliery Company purchased the old Glyn Levels in 1889 from the Blaendare Coal Company) by the Glyntillery Colliery Company, although this Company wasn’t established until 1912, and not incorporated until 1916. It is not on the listings for 1913, therefore I would prefer to assume that development was between 1912 and 1916.

On the 18th of March 1914, both William John Fisher aged 33 years and Ernest Bradford aged 21 years died and another two miners were injured in a gelignite explosion.

There were three entrances/exits, the haulage plane and the return were driven into the outcrop of the Brithdir seam while drainage adit was opened below them. The seam averaged around 32 inches in thickness in this area. Due to the absence of methane (firedamp) in this seam, it was permissible to use naked lights (candles) in the old days. This greatly improved the light available to the miner and made his life a little bit easier and a little bit safer. The downside was, with very little ground cover above them, rainwater soon made its way into the workings making them very wet indeed.

When Glyntillery was opened, the pillar and stall method of coal extraction was used, with either single or double stalls. The double stall system meant that fewer roadways and cross headings had to be driven, but this system was dependent on a strong roof due to the larger area in the workplace. In both of those systems, roadways were driven into the area to be worked, and off this roadway, cross headings were driven, around 75 degrees from the main road, and where practical, with the rise of the coal seam (if the headings followed the seam downwards there would be problems with water accumulating at the workplace, and extra cost in removing the drams of coal. The distance between the cross-headings would be about 60 yards with single stalls and double that with double stalls. Off the sides of the cross-headings, the stalls were opened to run parallel with the main roadway. The stalls were generally six yards wide a pillar of similar size between it and the next stall. Single stalls were only worked from one side of the heading and driven to within 9 yards of the adjoining heading before being stopped. The double stalls were driven from both sides of the cross-heading and continued until they hit through to the adjoining stall. Once they had reached their limit the collier would then work backwards taking away the pillars until it was too dangerous to do so.

In 1918 it employed 222 men underground and 29 men on the surface with the manager being G.J. Fisher. Mr. Fisher was still the manager in the following year but manpower had plunged to 60 men. Mr. Fisher was still the manager in 1927.

New Mine

On 30/1/1933 two men died at this colliery when they were buried under a fall of roof. Up until 1947, there were ten fatal accidents at this colliery.

In 1938 there were 114 men working underground and 15 on the surface with the manager being O. Thomas, and in 1945 it was W.J. Joshua. The Glyntillery Colliery Company was based at Penygarn, Pontypool, with the chairman being LI. Harmston and the directors were G.J. Fisher and M.G. Fisher. It was not a member of the Monmouthshire and South Wales Coal OwnersAssociation and retained control of Glyntillery until Nationalisation in 1947.

This mine was situated between the Hafodyrynys pits, to the west, and the Quarry level, to the east, and driven into the Tillery (Brithdir) seam which it worked at an average section of 44 inches, producing gas and house coals. It employed 183 men underground and 19 men on the surface in 1934 when the manager was G.J. Fisher.

On Nationalisation in 1947, Glyntillery was placed in the National Coal Board’s, South Western Division’s, Area No.6, and at that time employed 142 men underground and 27 men on the surface with the manager being W.J. Rees. It was still working the heading and stall method of coal extraction with estimated reserves of coal being 3 million tons.

In 1954 the NCB opened two new drifts to the west of the old ones and incorporated them into the new Hafodyrynys New Mine. This new Glyntillery Colliery was the first in the South Wales Coalfield to use electric locomotives underground. They travelled 1,200 metres into the mine. In April 1956, Glyntillery smashed its own productivity record by producing 3,080 tons of coal in six days. The previous best was 3,030 tons. They were at it again in July 1958 when they achieved a record 665 tons in one shift and 2,880 tons during a five-day week. In the 1957 NCB power-loading survey, one face was listed at this colliery as working the 44-inch thick Brithdir seam with a coalface length of 579 feet and manpower of 52 men. Coal cutting was by plough and the daily advance was 31.5 inches, the worse in the report. On the 17th of August 1959, it was merged with the new Hafodyrynys Mine.

In 1961 this colliery was placed in the No.6 Area’s, Abertillery Group along with Hafodyrynys, Tirpentwys, Roseheyworth and Cwmtillery collieries. The total manpower for this Group was 3,147 men, while total coal production for that year was 945,000 tons.

In 1975 the NCB informed the NUM that they were unwillingly to spend £1 million on boreholes to find coal in other areas which would extend the colliery’s life. They stated that the coal was very dirty, and the workings were very wet. Ploughs were used to mine the coal and the coalface was advancing by six feet per day giving an output of 650 tons a day. It was proposed to stop the last coalface, the T28, at a geological fault, beyond this fault was the outcrop of the Brithdir seam.

In April 1975 the manpower distribution was; on the coalface: 102 men, other work underground: 129 men and on the surface: 27 men. There were 180 of those men under the age of 55 years, 46 men between the ages of 55 and 60 and 32 men over the age of 60 years. The last coal was brought out on the 23rd of December 1975 with the colliery being officially closed on the 2nd of January 1976 on the grounds that the geology was poor.

Some Statistics:

- 1918: Manpower: 251.

- 1919: Manpower: 60.

- 1920: Manpower: 60.

- 1923: Manpower: 106.

- 1924: Manpower: 103.

- 1927: Manpower: 74.

- 1928: Manpower: 97.

- 1929: Manpower: 200.

- 1930: Manpower: 197. Output: 50,000 tons.

- 1932: Manpower: 200.

- 1933: Manpower: 158.

- 1934: Manpower: 165. Output: 60,000 tons.

- 1937: Manpower: 185.

- 1938: Manpower: 129.

- 1940: Manpower: 232. Output: 80,000 tons.

- 1943/5: Manpower: 159.

- 1947: Manpower: 169.

- 1948: Manpower: 171. Output: 65,000 tons.

- 1949: Manpower: 157. Output: 58,000 tons.

- 1950: Manpower: 144.

- 1953: Manpower: 129. Output: 69,000 tons.

- 1954: Manpower: Output: 117,000 tons.

- 1955: Manpower: 198. Output: 108,348 tons.

- 1956: Manpower: 211. Output: 114,554 tons.

- 1957: Manpower: 221. Output: 121,402 tons.

- 1958: Manpower: 230. Output: 116,748 tons.

- 1960: Manpower: 183. Output: 130,000 tons.

- 1962: Manpower: 226.

- 1971: Manpower: 255.

- 1972: Manpower: 265.

- 1975: Manpower: 258 plus 70 in Hafodyrynys washery.

This information has been provided by Ray Lawrence, from books he has written, which contain much more information, including many photographs, maps and plans. Please contact him at welshminingbooks@gmail.com for availability.

Return to previous page