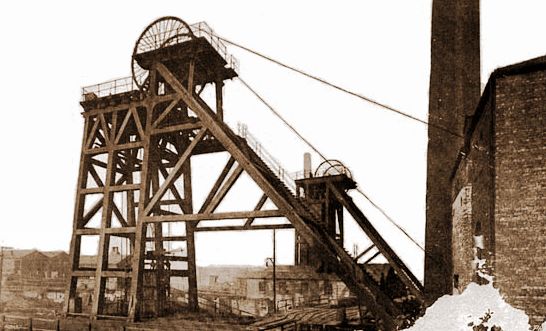

Bradford Colliery 1930

Image from www.healeyhero.co.uk

The isolated Central Manchester Coalfield possessed the richest coals in the whole of Lancashire. The Roger and so called ‘Crombouke’ mines were of first class quality, the Roger averaging 2% ash content with some areas as low as 1.7%. The Crombouke was not the Crombouke of the West Manchester coalfield, but was correlated with the Colonel Mine of the Oldham Coalfield lying to the east.

Coal was worked in the Bradford district of Manchester by the 1840s by Clegg and Livesey but by 1856 mining was in the hands of Thomas Livesey and others. The ‘modern’ colliery consisted of two main shafts 18 feet diameter, both of which were initially sunk to the Parker Mine at 540 yards from the surface. It was served by the Colliery Arm of the Manchester and Ashton under Lyne Canal. Later, a rail link was made with the L&YR Beswick branch.

The dip of the seams averaged 1 in 3 which was steeper than the coals in the West Manchester coalfield lying to the west of the Irwell Valley Fault. Around the turn of the century the downcast shaft was deepened to 927 yards with the ‘bottom seam’ being intersected at 2769ft 9in from the surface. This coal, otherwise known as the ‘Crombouke’, was extensively worked and by 1935 was being worked under 3800 feet of cover. The Roger Mine curiously was not reached by the deepening and lay a little distance below the shaft bottom. Nevertheless the Roger coal was extensively worked and for many years this and the Crombouke were the only seams being extracted.

In 1899 the Bradford Colliery Co. Ltd was formed which purchased the colliery from Thomas Livesey. Following the purchase considerable development was undertaken including the deepening of the downcast shaft already mentioned, this becoming known as the Deep Pit. The upcast shaft – the Parker Pit – was not deepened at this time. A new winding engine was installed at the Deep Pit in 1906 by Robert Daglish of St. Helens. The colliery was situated in one of the most densely populated areas of Manchester, hemmed in by rows upon rows of terraced houses. The site was very cramped and accommodated a brickworks as well as the colliery plant. To save precious space the winding engine was a twin-cylinder vertical. It was a large engine with a 25ft diameter drum and 42in x 72in cylinders. The shaft headgear was of timber and the winding depth 902 yards. The cages were as large as could be accommodated carrying six 10cwt capacity tubs, with three tubs per deck. Four wire rope conductors were provided for each cage and there were two rubbing ropes between the cages.

The Parker Pit was the upcast ventilation shaft and was also used for winding men. A twin cylinder horizontal winding engine was installed here of unknown make but fitted with Daglish’s automatic cut-off on the inlet valves. The cylinders were 36in x 78in. Two winding drums were fitted each 18ft 8in diameter by 4ft 7in wide, located one on each side of a 15in wide brake path. Two cages were wound each being guided by four rope conductors with two rubbing ropes between. A new headgear of massive timber construction was erected in 1925.

An old shaft – the Forge Pit – oval in cross-section and 155 yards deep was also in use for pumping. This shaft was 9ft 6in across the widest part. Winding was by capstan.

Ventilation was provided by a ‘Sirocco’ forward bladed centrifugal fan 8ft 6in diameter by 4ft 6in wide which could circulate 200,000 cubic feet per minute against three inch water gauge. The fan could be driven either by electric motor or by a steam engine. This was an inverted vertical compound 18.5in + 29in x 24in with Corliss valves built by Hick, Hargreaves of Bolton, and running at 90rpm. It drove the fan through 10 cotton ropes one and a half inch diameter.

In 1900 Messrs J.H. Holmes of Newcastle-upon-Tyne installed an extensive electrical plant, one of the earliest such schemes at a colliery. Direct current was generated at 525 volts by high speed inverted vertical enclosed engine sets. The largest engine had a high pressure cylinder 24in bore by 12in stroke and two low pressure cylinders each 27in x 12in. Running at 250rpm the engine developed 500 horse power and was direct coupled to a 340kW dynamo. Two smaller engines of equal size were also installed these having one high pressure and one low pressure cylinder 14.5in + 24in x 10in. Running at 380rpm each engine developed 195hp and was coupled to a 130kW dynamo. All the engines were built by Browett, Lindley, of Sandon Works, Patricroft and each engine was fitted with a condenser. For lighting purposes current was generated at 230 volts by a 47kW motor generator set and a 15kW engine set with an open crank inverted vertical engine 9.5in x 9in running at 225rpm.

Power was supplied underground through lead covered armoured cables to serve four haulage engines, two pumps and a tub creeper. At the surface power was supplied to two 80hp motors driving the screening plant and a 15hp motor which powered the carpenters’ shop.

The generating plant was subsequently enlarged by the installation in 1913 of a 700kW mixed-pressure turbine set running at 1,800rpm and was later further increased by the installation of a 1000kW mixed pressure turbine set, again running at 1800rpm.

Steam was supplied to the colliery by a range of eight Lancashire boilers working at 100psi. There were three sets of Green’s economisers and three chimneys. Exhaust steam from the winding engines not required by the mixed-pressure turbines was turned into one of the chimneys.

In 1935 the colliery was purchased as a going concern by Manchester Collieries Ltd. At the time of purchase the colliery had a history of profitability due to its position in the centre of the Manchester conurbation and to the excellent coal produced. However, output was low and also productivity. A short term improvement programme was introduced which involved developing the excellent Roger seam, improving roadways and haulage and coal face methods. This had the effect of increasing output from 171,557 tons in 1937 to 243,363 tons in 1940. Over the same period output per manshift increased burn 16.34cwt to 25.03cwt.

There was also a gradual change over from direct current to alternating current for power purposes. This was purchased from Manchester Corporation, and by the end of 1946 the DC requirements were being met by an AC/DC motor-generator set with one of the 130kW engine sets as stand-by.

The coal reserves available at Bradford Colliery were remarkable. Not only was the coal of very high quality, but the workable seams accounted for no less than 310 million tons of resources. Although the angle of dip was quite steep other features were very favourable. The colliery was virtually free of water, gas emission was low and the geothermic gradient was considerably less than in the West Manchester coalfield, so that the deepest workings were relatively cool.

Although the colliery was operating very successfully after the short term improvements had been carried out, the output was limited to about 900 tons per day due to winding capacity at the Deep Pit. Because of the high quality of the coal worked much of the small coal was sold ‘dry’ without washing and large coal was taken straight off the picking belts by the screen hands and loaded direct into waggons or road vehicles without any treatment. Even so, the capacity of the coal preparation plant placed a restriction on output. At the time of purchase by Manchester Collieries Ltd the coal preparation plant consisted of a set of screens erected by Messrs Goodall-Clayton, six Hugh Wood spiral separators and four concentrating tables. The screens could deal with 162 tons per hour and the spiral separators and concentrating tables could handle 70 tons and 20 tons per hour respectively.

To improve the output of the colliery a long-term programme of development was drawn up which envisaged increasing output to 4000 tons per day. The scheme involved the complete replacement of the surface plant and increasing the space available by demolishing the adjacent brickworks. Underground the workings were to be laid out on the ‘horizon’ principle with coal winding at the Parker or upcast shaft which was to be deepened and skip winding installed. Transport underground was to be by a combination of three ton mine cars and conveyors with battery locomotive haulage of the mine cars. Winding arrangements at the Deep Pit were also to be replaced to allow mine cars to be wound for materials supply and dirt.

Deepening of the Parker Pit commenced in 1944 and by the end of 1946 had reached 888 yards. The shaft was completed to 955 yards in 1948 and skip loading was installed at 897 yards. Two sets of rigid guides were installed in the shaft to take 12-ton capacity skips. The electric winder was of the Koepe friction wheel type built by Metropolitan-Vickers. The headgear was of reinforced concrete 200 feet high and to take its weight the upper portion of the shaft was strengthened by re-lining with concrete.

A new headgear and electric winder were provided at the Deep Pit, the winder having clutched drums so that two-cage winding could be carried out from different levels.

Ventilation under the new scheme was by two axial flow fans and because of the lack of space these were installed in a chamber below ground level.

Under the new scheme of working solid stowing of the waste or goaf areas was to be under-taken, this being an economic proposition where working under such a densely populated area extracting coal of high market value. As the workings developed the colliery made insufficient dirt and ‘foreign’ dirt was brought in from other collieries and wound down the pit. Prior to reconstruction the colliery had no major air compressing plant and to power the stowing machines three electrically driven turbo-compressors were installed each having a capacity of 7500cfm delivered at 80psi. Synchronous motors were fitted having Metropolitan-Vickers VAX controllers which enabled the excitation to be automatically adjusted so that the overall electrical power factor of the colliery was improved.

A new coal preparation plant was built on the old brickworks site. A ‘Tromp’ washer was installed for coal sized 6in to 2in and a Baum Jig washer for coal under two inches. As in the old plant very large coal was taken straight off the conveyor delivering from the skips and sent down a chute into waiting lorries. The railway outlet for coal despatch was dispensed with and road transport almost wholly used. For small coal a 500ft long tunnel of 10ft diameter was driven 55ft below ground level through which ran a conveyor taking coal direct to Stuart Street power station.

Following Nationalisation the ‘takes’ of Moston Colliery and Ashton Moss Colliery were incorporated into the reconstructed Bradford Colliery. These collieries lay to the east on the western edge of the Oldham coalfield. Moston Colliery was closed completely but Ashton Moss was retained to wind men and materials. These extensions increased the forecasted life of the colliery by a considerable extent but these hopes were not fulfilled and the colliery closed in August 1968 with the large reserves virtually untouched.

Sources:

- Hayes, H. (2004) Collieries and their Railways in the Manchester Coalfields (Ashbourne: Landmark Publishing)

- NMRS Records, Gazetteer of British Collieries

- National Archives: BT31/2135/9808 (1875) – Bradford Coal Co. Ltd