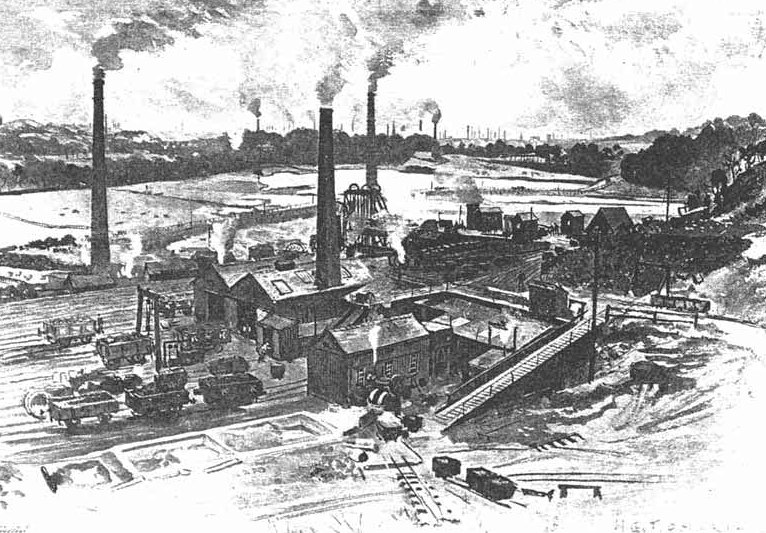

Clifton Hall Colliery

Situated in the Irwell Valley, Clifton Hall Colliery was known locally as Lumb’s Pit. It was notorious for the devastating explosion which took place in the Trencherbone Mine in 1885 causing the deaths of 178 miners. Its intensity was such that the concussion was felt at the surface. The two shafts were 11 yards apart with a diameter of 10 feet and were commenced in 1838 making this another of the early modern collieries. The shafts were eventually sunk to the Cannel Mine, the depth to the bottom of the shafts being approximately 606 yards. The down-cast was originally the only coal winding shaft and a single cylinder 42in x 72in vertical winding engine was erected by J. Musgrave in 1858. Cornish valves were fitted and the engine had a spiral drum 14ft to 25ft diameter.

Ventilation was by furnace until 1886 when a Cockson Patent fan was installed by Messrs Black, Hawthorn of Gateshead. The fan was 24ft diameter and was driven by eight cotton ropes from the flywheel of a 36in single cylinder horizontal engine also made by Black, Hawthorn.

Around the turn of the century improvements were carried out at the colliery and the up cast shaft was fitted out for coal winding. The winding engine installed was a twin-cylinder horizontal said to have been built by Messrs Robert Daglish of St Helens. It is not known whether this engine was new, but in the light of improvements made at other Andrew Knowles collieries at about this time it could well have been second-hand.

In the early 1890s the boiler plant consisted of five Lancashire and two Cornish boilers the latter being fired by waste gases from a battery of coke ovens. There were also two Lancashire boilers underground situated near the pit bottom which supplied steam to the underground haulage engines.

The surface boiler plant appears to have been renewed around the turn of the century and the final complement was 12 Lancashire boilers working at 100psi. The use of steam underground also ceased about this time being substituted by compressed air. A large single stage air compressor was obtained second-hand about 1924/25. This was a cross-coupled set with two 28in x 60in steam cylinders and two 30in bore air cylinders. It had been built by Walker Bros., Wigan, in 1897 for the Eaglesbush Colliery Co. Ltd.

Unlike other Andrew Knowles collieries in the locality, Clifton Hall had a rail outlet from 1850 when the former London & North Western Railway Patricroft-Clifton branch was opened. A Robinson type coal washer was installed by Wood & Gee during the latter years of the 19th century but this appears to have been subsequently replaced by a washer built by Greaves. This latter was in service until 1956 and had a capacity of 55 tons per hour. Dirt disposal was by an aerial ropeway to a nearby tipping site.

Clifton Hall Colliery closed in 1929 but the coal washing plant was retained as it also dealt with output from Wheatsheaf Colliery. One of the shafts was also retained for ventilation of part of Wheatsheaf Colliery workings.

On the 19th June 1885 a massive explosion of methane gas claimed the lives of 178 miners. The full report can be found here.

CLIFTON HALL – No.1 Pit

| Ft | Ins | |

| Bin Mine | 388 | 7½ |

| Shuttle Mine | 478 | 6½ |

| Crombouke Mine | 485 | 6½ |

| Rams Mine | 636 | 2 |

| White Mine | 981 | 8 |

| Black Mine | 1071 | 6 |

| Dow Mine (Doe Mine) | 1266 | 6 |

| Five Quarter Mine | 1308 | 9 |

| Hell Hole Mine | 1420 | 6½ |

| Trencherbone Mine | 1601 | 11½ |

| Cannel Mine | 1768 | 6½ |