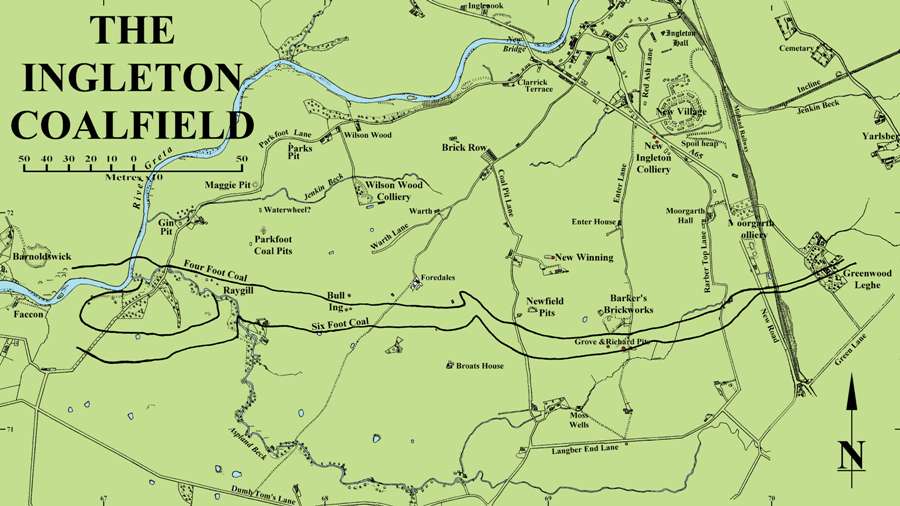

The Ingleton Coalfield is about six miles long, being bounded on its north-east side by the South Craven Fault, from Cold Cotes, two miles south-east of Ingleton, to Leck Beck, some four miles to the north-west. It is shaped like a segment of a circle, the chord of which is the fault.

The Coal Measures are split into two distinct groups of strata by an unconformity. The lower group contains the workable coals, and the higher one has no workable coals. The unconformity marks a break in deposition which allowed the exposed upper surface of the lower measures to be eroded unevenly before being covered by new sediments. As a result, the thickness of coal bearing strata varies considerably and in places the coal seams have been removed altogether. Mining was, therefore, confined to the southern part of the coalfield, where the seams dip northwards at 1 in 4, but in places are even steeper.

There are several coals, but not all of them were worked, because they were either too thin or of poor quality. The Ten and Nine Foot seams only covered a small area before they hit washouts and had been eroded away. Their existence was unknown until they were discovered during the sinking of New Ingleton Colliery. The Four Foot seam was regular in thickness, with no dirt bands, and was said to “burn with a bright flame and makes a very hot fire”. The Three Foot, or Yard, seam was separated from the Four Foot, above it, by a layer of fireclay around two feet thick, usually known in Ingleton as ‘sill’. The coal was said to be of a good quality and to burn brightly, leaving a red ash. Nevertheless, the seam was also more variable than the Four Foot Seam and it appears to have been considered as inferior.

The Six Foot seam, also known as the ‘Deep or Bottom Coal’, varied between three and five layers, or leaves, of coal separated by thin partings of shale, called dirt bands. The thickest of these leaves was near the middle of the seam and, in 1897, was classed as ‘steam coal’. The leaves above and below it were classed as ‘house coal’. The dirt and coal were kept separate when the coal was cut by hand, but it had to be well-screened when the railway began importing better quality coal. It was often mixed with Four Foot coal to improve its quality.

The Lowther family, lords of the manor of Ingleton, had a colliery there by 1645, but mining is likely to have begun earlier. These early mines were in the Parkfoot-Raygill area, near the River Greta, where the seams outcropped.

The Serjeantson family inherited the manor of Ingleton in the 1730s and kept the pits working. By 1828 coal was being worked at Faccon, and in the Yarlsber area, near Ingleton, but they needed to move into fresh areas. By 1830, they had sunk the New Winning, followed by Wilson Wood in 1853, with other pits at Moorgarth. Wilson Wood was abandoned in 1866, when the workings flooded, and many men were thrown out of work.

The Serjeantson family inherited the manor of Ingleton in the 1730s and kept the pits working. By 1828 coal was being worked at Faccon, and in the Yarlsber area, near Ingleton, but they needed to move into fresh areas. By 1830, they had sunk the New Winning, followed by Wilson Wood in 1853, with other pits at Moorgarth. Wilson Wood was abandoned in 1866, when the workings flooded, and many men were thrown out of work.

William Bracewell took over the mines in 1872 and began pumping some 58 million gallons from the workings. The surface plant was rebuilt, with powerful new pumping engines, and the mine was producing again in 1874. Bracewell died in 1885 and his trustees closed the colliery in 1887, after selling much of the plant. With the deeper coals flooded, a number of small, shallow workings were opened, and a few men kept on. There was even a small brickworks.

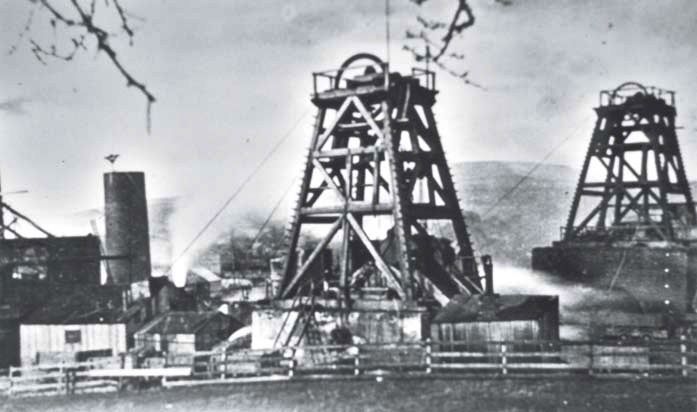

New Ingleton Colliery was sunk to the Six Foot Coal between 1912 and 1914, when production began. The second shaft was not completed to its full depth until 1917 because of the war, and so the shallower Nine and Ten Foot seams were worked instead. For the only time an Ingleton colliery was linked to a main line railway.

Some Six Foot coal was worked in the early years, but most work was done in the Four Foot Seam, which was found to be regular in thickness and quality, free from washouts and faults, and to have a good roof. The 1920s were a time of over capacity and production quotas in the coal industry, and they ended in the Wall Street Crash of 1929. In order to increase efficiency, therefore, the company introduced electrical power by 1926. Compressed-air-driven coal-cutters were replaced by electrically-driven ones, and endless-rope haulage was introduced on the main haulages. This reduced the number of horses employed and made their handlers available for other work.

The mine’s final year saw industrial problems and the company, which was in difficulties, closed it in February 1936. This was the end of mining at Ingleton until, on June 14th 2004, a memorial was unveiled to over 300 years of the coal mining industry at Ingleton.

Bentley, J.I., Bond, B.R. & Gill, M.C. Ingleton Coalfield 1600-1940 (British Mining No.76, 2005)

Kelly M. Geology of the Lune and Upper Ribble Coalfields, British Mining No.85, 2008