SWANNINGTON INCLINE SK 420158

Although the Swannington Incline was not part of any colliery, being constructed by the Leicester & Swannington Railway Company, it was nevertheless an integral part of the Leicestershire coalfield in the Swannington – Coleorton district.

The incline was the extremity of the Leicester & Swannington Railway and was 33 chains (664 metres) in length on a falling gradient of 1 in 17 towards the terminus. The gradient was against the load and the incline was single track. Both of these features meant that a winding engine was required at the top of the incline.

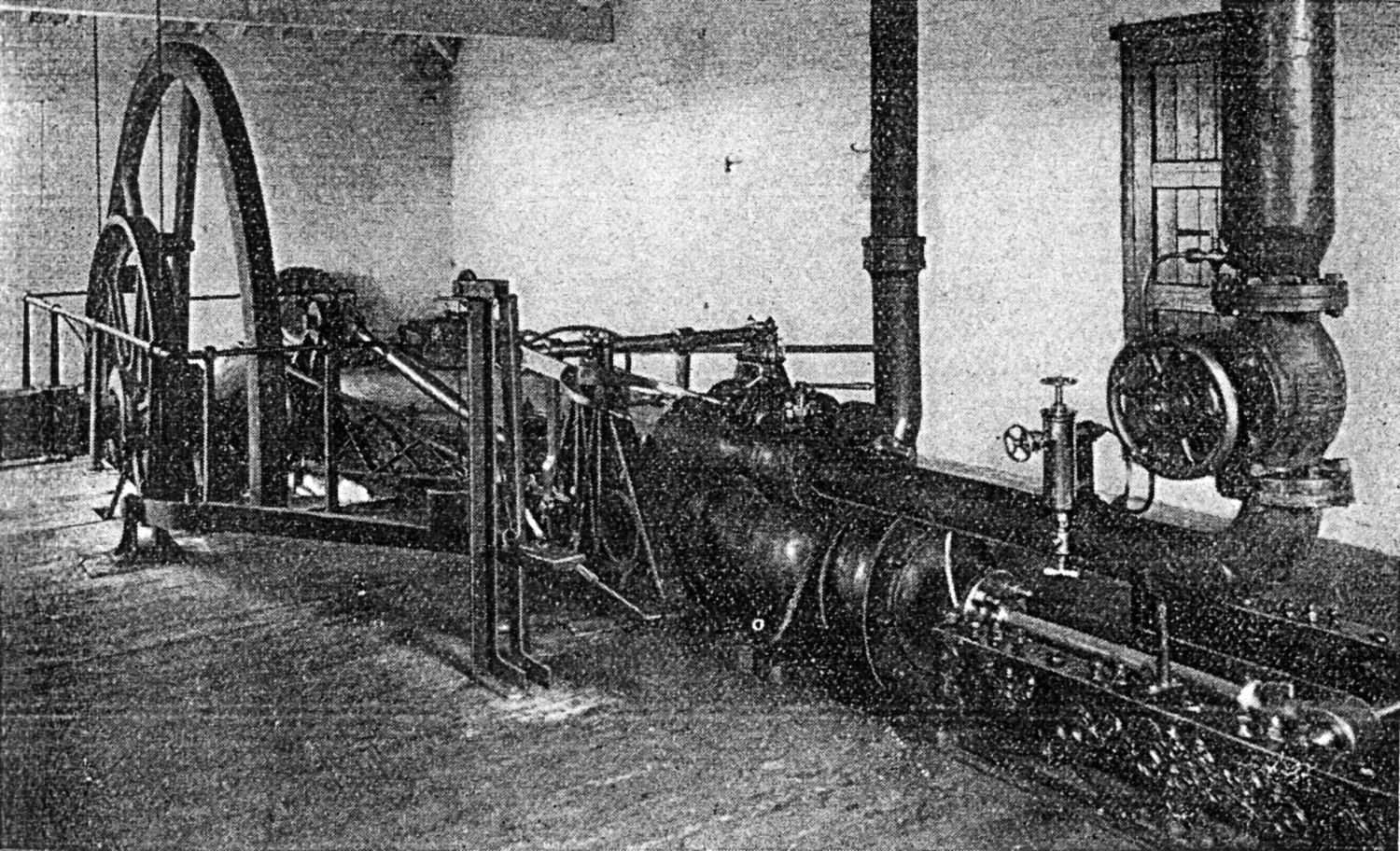

Single cylinder horizontal winding engine built by the Horsley Iron & Coal Co 1833

Railway Magazine (Article by Charles E. Lee), July 1939

The winding engine was a single cylinder horizontal, built by the Horsley Coal & Iron Company in 1833. Cylinder dimensions were 18¼in. bore by 42in. stroke and steam distribution was by a piston valve. Horizontal engines and piston valves were unusual at this date, especially the latter feature. The valve gear was of the gab type with a loose eccentric on the crankshaft. The eccentric rod had a slot or hook which could be engaged or disengaged from a pin fixed on the valve rod of the piston valve. Disengagement was by a driver1s foot pedal which enabled the driver to operate the piston by hand by means of a pair of “barrow handles”. Once the engine was running satisfactorily in the desired direction the foot pedal was released to allow the eccentric rod to drop and engage with the piston valve rod and the engine carried on running without any further attention from the driver. At a later date a wheel with a brake path and a band brake were fitted alongside the flywheel. The brake was applied by a long lever with a foot pedal. The engine drove a winding drum located in a pit between the rails at the top of the incline, through a single reduction gear from the crankshaft. There was also, apparently, a clutch incorporated in the drive system which would allow the engine to be run free.

The incline was opened to traffic towards the end of November, 1833, but on 29 November the engine suffered a major breakage. Repairs were not completed until 7 March 1834.

No records appear to have survived about the type of boiler which originally supplied steam to the engine. An egg-ender is a strong possibility. It is known however, that a new replacement boiler was installed in 1839. Charles E. Lee writing in 1939, stated that the boiler then in use was a “comparatively modern one”, with a working pressure of 80psi. Anecdotal evidence, unconfirmed, is that it was a locomotive type boiler but whether it was second-hand off an actual locomotive or made specifically for stationary use is not known. The Midland Railway made locomotive-type boilers especially for stationary use, as well as purchasing them from other manufacturers. According to Charles E. Lee, the boiler feed pump was operated by a small steeple engine made by Carrett, Marshall & Co. in 1859.

With the running down of mining in the Swannington-Coleorton district during the 1870’s, the main function of the incline was now to supply coal to the Calcutta Colliery pumping engine. The original intended duty was now reversed, loaded coal wagons now being lowered down the incline and empty wagons drawn up. The load limit for the engine was 3 loaded or 6 empty wagons in either direction on the incline but the usual load was 4 empty wagons hauled up. With the installation of electric pumps at Calcutta Colliery in 1947, the need for the incline was now ended. The last wagons of coal were lowered down on 20 September 1947 and the last empties hauled up on 14 November. The incline was officially closed in February 1948.

The winding engine was dismantled and in January 1952 was taken to the York Railway Museum, then at its former premises, and put on display. With the establishment of the new museum, the engine was duly transferred and continues to be displayed there.

Return to previous page