Trelewis, Taff Bargoed Valley

This was a highly productive drift mine opened at a cost of £408,000 by the National Coal Board in 1954 to work the Brithdir seam from near the surface of Taff Merthyr Colliery. The main drift was sunk to a distance of 342 yards at a gradient of 1 in 4. It was 14 feet high and was expected to expose 4.75 million tons of reserves. The Brithdir seam was worked at a section of 1.78 metres with coalface length varying from between 135 and 200 metres. Coal cutting was done by ranging drum shearer and roof supports on the coalface were the self-advancing types.

This was a highly productive drift mine opened at a cost of £408,000 by the National Coal Board in 1954 to work the Brithdir seam from near the surface of Taff Merthyr Colliery. The main drift was sunk to a distance of 342 yards at a gradient of 1 in 4. It was 14 feet high and was expected to expose 4.75 million tons of reserves. The Brithdir seam was worked at a section of 1.78 metres with coalface length varying from between 135 and 200 metres. Coal cutting was done by ranging drum shearer and roof supports on the coalface were the self-advancing types.

In 1954 this colliery was placed in the N.C.B.’s, South Western Division’s, No.4 (Aberdare) Area, No.4 Group, and at that time employed 13 men working at the surface of the mine and 164 men working underground. The manager was V.D. Savage.

In 1955 out of the total colliery manpower of 88 men, 36 of them worked at the coalfaces, this coalface figure rose to 70 men in 1956, to 89 men at the coalfaces in 1957, but was back down to 86 men working at the coalfaces of this colliery in 1958. The additional men at the coalface had the desired effect and output per manshift at the coalface rose from 48 hundredweights in 1957 to 59 cwts in 1959, and during the ‘bull’ week where earnings counted for the Christmas pay, it rose to a staggering 90 hundredweights per man.

On the 25th of June 1958, the Times reported that at this drift they were experimenting with using high-velocity water jets to cut the coal off the coalface. When the coal is broken into bits the water then flows it to a point of collection. The cost of the trial was estimated to be £48,000 over a six-month period.

Forever looking for different methods to mine coal, the National Coal Board visited Russia in 1956 to look at a method of cutting coal by waterjets. They decided that this method was worth looking at in-depth and decided to use Trelewis Drift as the site of an experiment of this method. Simply put, the water jets would break the coal down, and then clear the floor of the coal by sweeping it out to the surface thereby eliminating the need for conveyors and underground electrical equipment, and thus reducing the risks of explosions. Four men were needed at the coalface, one to operate the monitor, and the others to attend to the pipes and flumes and erect the roof supports. This experiment had two parts; it was to cut the coal from the coalface in one part, and then transport it away in the second part.

The seam was 175cm thick with a hard shale roof and floor, the Brithdir seam dipped by 1 in 14.7. High-pressure water was piped 900 metres to the test area and was received at a pressure of between 42 and 80 bar. The coal was to be extracted from either side of the roadway by a high-pressure hose, but it was found almost immediately that the operator was in danger from flying coal as far back as 12 metres from the operation so a remote control method was devised. In driving the heading/roadway forward it was found that 25 tonnes of coal per hour could be achieved in a heading 1.9m wide with the jets situated two inches from the coal, in 40 minutes it could cut 3.6m forward but was slowed down by a stone band of 10 cms thickness in the seam. Once the heading was far enough forward, it was decided to work back towards the drift entrance, which is called the retreat method, but unfortunately, when cutting with the high-powered water jets on either side of the road it also brought collapses of the roof, one of which buried the monitor. They also encountered blockages of the channels dug along the floor to take the coal away. Output of coal averaged 40 tonnes an hour with thirteen men employed on the experiment from the surface to the coalface. Production rates were calculated at 45 tonnes per shift driving the heading, and 132 tonnes per shift on the retreat work. The capital cost of the experiment was £66,833.00. It was estimated that the cost per tonne would be 50 pence (1963). The outcome of the experiment was that this system needed flat, ideal conditions to operate in, and in those conditions, other methods of extraction would yield better results, therefore it was decided that “hydraulic mining would not be the answer.”

In 1961 this colliery was still in the No.4 Area, No.4 Group along with Deep Navigation, Merthyr Vale and Taff Merthyr Collieries. This Group had a total manpower of 3,398 men in that year, and a total coal production of 1,042,000 tons making it the most productive Group in the South Wales Coalfield. The Group Manager was H.G. Evans and the Area Manager was T. Wright. In 1969/76 the colliery manager was D.M.J. Evans, in 1977/79 it was W.G. Cecil. In 1980 the manager was A.J. McGrew.

The Times of the 30th of April 1968 reported:

“A strike of 280 miners at Trelewis Drift mine near Merthyr Tydfil is said to have been sparked off by the use of a four-letter word by the manager. The manager apologized to the union lodge, explaining that his words had not been directed to them but were made while talking to the deputy manager.”

In January 1970 this drift broke their own South Wales Coalfield output record when they attained an output per manshift of 188.4 hundredweights which was 26 hundredweights more than the old record. Each man on the coalface was producing 57 tons of coal per shift with a total output for the week of 8,779 tonnes of coal. It was the highest output and with the lowest manpower, in the East Wales Area. Each man received eight pints of beer from the manager.

In 1975, it was fair to say that the South Wales coalfield was not as developed as the other coalfields when it came to Mechanisation, but that was not the case at Trelewis Drift. During the Year the drift mine produced 80.9 cwts per man shift as a result of almost total mechanisation at the mine.

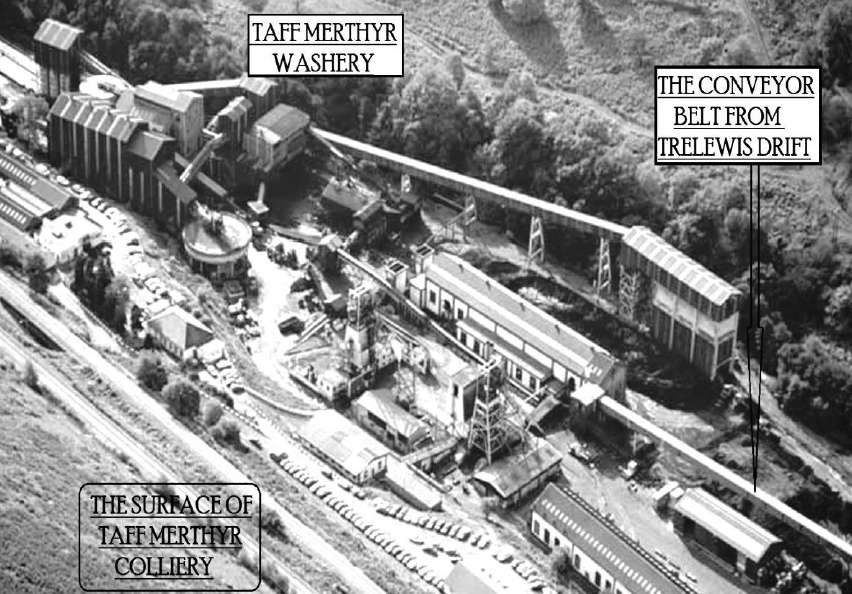

Trelewis benefitted from the major reconstruction at Taff Merthyr Colliery in 1976 where the surface of the colliery was completely renewed at a cost of £7.7 million which included a new washery and merry-go-round trains being loaded with both Taff Merthyr and Trelewis coal from an 1,800-ton bunker in twenty minutes.

Trelewis benefitted from the major reconstruction at Taff Merthyr Colliery in 1976 where the surface of the colliery was completely renewed at a cost of £7.7 million which included a new washery and merry-go-round trains being loaded with both Taff Merthyr and Trelewis coal from an 1,800-ton bunker in twenty minutes.

In July 1979 the A12 coalface was the best-performing retreat coalface with a seam thickness of over 150cm in the South Wales Coalfield. It produced 1,324 tonnes of coal per day. In 1981 the B12 Coalface was advancing at a rate of 4.26 metres a day, with output per manshift on the coalface being 17.67 tonnes, the highest in the Coalfield, the overall output per manshift for the colliery at 2.47 tons. Unfortunately, the saleable yield from the Brithdir seam was only 50% to 70%. Manpower distribution at that time was; working at the development of new coalfaces, 30 men, working at the coalfaces, 40 men, working elsewhere below ground, 232 men, working at the surface of the drift, 42 men. The manager at that time was D. Roberts. Records continued to tumble, in January 1982 the W4 Coalface advanced 21.85 metres in five shifts producing over 10,000 tons of coal. The eleven men on the face produced an output per man shift of 83.87 tons. In 1983 the NCB reported that this colliery was losing £14.30 on each tonne of coal that it produced.

Trelewis Drift made a good recovery following the 1984/85 miner’s strike obtaining 87% of expected output within a month. In 1988, 280 men produced 470,000 tonnes of coal for power stations.

It was closed by British Coal in 1989 the manager at that time was D. Fox.

The colliery was not completely demolished and the site was turned into a Climbing wall Facility and Gym, but has suffered financial problems for many years.

Some Statistics:

- 1955: Manpower: 88. Output: 29,754 tons.

- 1956: Manpower: 184. Output: 94,977 tons.

- 1957: Manpower: 205. Output: 116,089 tons.

- 1958: Manpower: 216. Output: 138,252 tons.

- 1960: Manpower: 218. Output: 131,000 tons.

- 1961: Manpower: 208. Output: 121,219 tons.

- 1962: Manpower: 219.

- 1969: Manpower: 291.

- 1970: Manpower: 288.

- 1971: Manpower: 296.

- 1972: Manpower: 287.

- 1974: Manpower: 320. Output: 300,000 tons.

- 1979: Manpower: 351. Output: 306,000 tons.

- 1981: Manpower: 382.

- 1984: Manpower: 296.

- 1989: Manpower: 296.

- 1990: Manpower: 280.

Information supplied by Ray Lawrence and used here with his permission.

Return to previous page