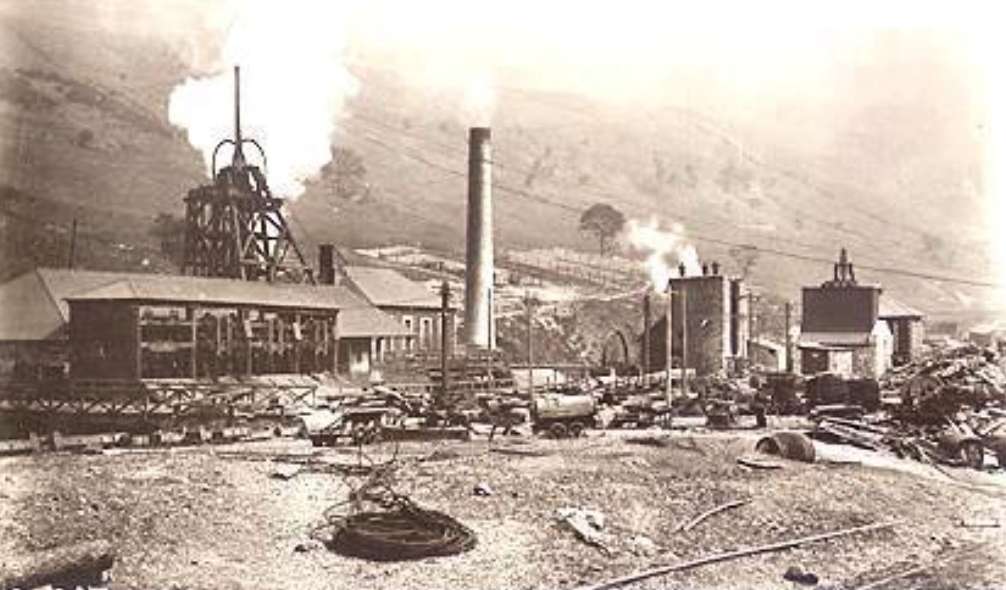

Blaengarw, Garw Valley (90549311)

David Davies, the founder of the Ocean Coal Company along with Thomas Webb, Morgan Joseph, John Osborne Riches, Abraham Howell and E. Roberts first ventured into coal mining with sinkings in the Rhondda Fawr Valley in 1866. They formed David Davies and Company in 1867, expanded into the Ogmore Valley in 1873 and into the Garw Valley in 1883 with the sinking of Garw Colliery which cost £46,674.

David Davies, the founder of the Ocean Coal Company along with Thomas Webb, Morgan Joseph, John Osborne Riches, Abraham Howell and E. Roberts first ventured into coal mining with sinkings in the Rhondda Fawr Valley in 1866. They formed David Davies and Company in 1867, expanded into the Ogmore Valley in 1873 and into the Garw Valley in 1883 with the sinking of Garw Colliery which cost £46,674.

At Garw the Two-Feet-Nine seam was found at a depth of 182 yards, the Four-Feet at 200 yards, the Six-Feet at 238 yards, the Red Vein at 243 yards, the Nine-Feet at 271 yards, ‘Brunts’ at 299 yards, Three-Feet-Ten at 316 yards, Phils’ at 331 yards, the Upper New at 370 yards, the Lower New at 386 yards and the Garw seam at a depth of 394 yards. The downcast ventilation shaft was fifteen feet in diameter, while the upcast ventilation shaft was fourteen feet in diameter. They were 144 feet apart and were sunk between 1884 and July 1885.

Ventilation was by a Schiele type fan which was 13 feet 6 inches in diameter. The first coal was wound in 1886, and a subsidiary company called the Blaengarw Ocean Coal Company was formed to run the pit. This company was a member of the Monmouthshire and South Wales Coal Owners Association. In 1884 the manager was Rowland Rowlands and in 1896 the manager was David Matthews this pit employed 462 men underground and 78 on the surface. The following seams were worked:

- The Gellideg seam was worked at a thickness of 48 inches.

- The Lower-Seven-Feet seam was called the Upper-Five-Feet or Little seam at this colliery and was worked at a thickness of 34 inches of mixed coal and dirt.

- The Middle-Seven-Feet seam was worked and had a thickness of 83 inches of mixed coal and dirt.

- The Yard seam was known as the Seven-Feet seam and was worked with a thickness of up to 62 inches.

- The Bute seam was extensively worked and called Brunts, it had a thickness of 70 inches.

- Also worked extensively was the Lower-Nine-Feet seam which was called the Bute at this colliery, it had a thickness of between 40 inches to 63 inches.

- The Red Vein seam had a thickness of 65 inches, and the No.2 Rhondda seam had a thickness of between 32 inches to 40 inches. Both seams were worked extensively.

- The Lower-Six-Feet seam was worked and had a thickness of, coal 48 inches to 66 inches, dirt 2 inches, coal 16 inches to 32 inches.

Generally, this colliery produced types 203 and 204 Coking Steam Coal, they were weak to medium and medium to strong caking, low volatile and low in ash and sulphur content. They had a wide variety of uses from steam raising in boilers for ships, locomotives, power stations, etc., to foundry and blast furnace coke, to coking blend.

The Western Mail newspaper of Wednesday, 18th of May 1887, reported:

“A shocking accident occurred early on Tuesday morning at the Ocean Colliery, Blaengarw. Three men were engaged in ripping, when a large stone fell upon them and killed two of the men on the spot, namely, William Roberts, of Alexandria-road, Pontycymmer, and John Griffiths, who, we hear, came to the valley from the Rhondda. The other man, Richard Davies, who also resides at Alexandria-road, and who is a prominent member of the Methodist Connexion in the valley, was seriously injured, and is now lying in a critical condition.”

The Ocean Coal Company continued to expand by acquiring Deep Navigation Colliery in 1893, by sinking Lady Windsor Colliery in 1895, Avon Colliery was purchased in 1912, and by 1913 the Company employed over 9,000 men, 756 at Garw Colliery. The manager at Garw Colliery was then William Jenkins. In that year the Director and General Manager of the Company was Thomas Evans and the General Manager, William Jenkins. In 1915 the Business Statistics Company, in its book called ‘South Wales Coal and Iron Companies’ reported that the Company was called the Ocean Coal and Wilsons Limited and that this company:

“was registered in March 1908, to acquire and hold all or any of the shares of the Ocean Coal Company Ltd, and Wilson, Sons & Co, Ltd, and any Company in which either of such Companies has or have any interest. The Ocean Coal Co, work 9 collieries…the normal annual output of the Collieries is about 2,500,000 tons of coal Wilson, Sons & Co, has Coal Depots…In addition to their regular business of Coal Merchants and Steamship Agent, the Company owns engineering shops and foundries at Pernambuco, Dakar, Bahia, Rio de Janeiro, and have executed many important engineering contracts.”

The book continued to state that the assets of the combined company were £4,886,982 with profits of £301,266 available for distribution. The board of directors was; David Davies, Chairman, A.E. Bowen, William Jenkins, Edward Jones, Thomas Evans, Henry Webb, Alfred Harley, E.E.M. Hett and F.J. Yarrow. The manager in 1916/23 was T.E. Lewis. In 1927 it was H. Davies and in 1930 J. Breacher.

With the support of some of the owners, particularly the Ocean Coal Company, a “non-political” union; the South Wales Miners Industrial Union, began to emerge in the Coalfield. This union was particularly strong at Taff Merthyr Colliery where 500 men joined it following the 1926 lock-out and from there it spread throughout the Coalfield establishing itself mainly at Raglan Colliery, Emlyn Colliery in the anthracite district, the Garw Valley, Park and Dare in the Rhondda and Bedwas Colliery in the Rhymney Valley until by January of 1927 it claimed to have twenty-one branches and a membership of 30,000, a figure hotly disputed by the South Wales Miners Federation.

The Ocean Company was a great promoter of this Union in an attempt to break the power of the South Wales Miners Federation and encouraged their men to join it, guaranteeing them work even when the colliery was closed down for short periods due to lack of orders. In October 1929 the South Wales Miners Federationmen at this pit went out on strike for three weeks over this issue and, as it turned out temporarily, won their case. This strike was unique in that it was the first time that the South Wales Miners Federation had paid their members the equivalent of ’dole’ money while they were on strike.

In 1930 Garw Colliery lay idle for 105 days, and in 1931 it lay idle for 119 days, in both cases due to lack of orders, but this lack of work did not dim the militancy of the workforce, and the matter of ’scab’ labour simmered on culminating in the stay-down strike of 1935 in support of the Nine Mile Point Colliery dispute.

In 1934 the Ocean Coal Company Limited was based at 11, Bute Crescent, Cardiff with the directors being; Lord Davies, Sir H. Webb, W.P, Thomas, E. Emrys Jones, A.E. Yarrow, A.J. Cruikshank and T. Evans. The company secretary was M.A. Anderson. In 1935 the colliery employed 114 men on the surface and 577 men underground with the manager being J. Breacher. At that time ventilation of the colliery was by a Waddle type fan which was 15 feet in diameter. It was part of the Ocean Empire that was second only to Powell Duffryn in the South Wales Coalfield. Production of coal for the company was 2,750,000 tons, with 7,921 men employed.

In 1937 the Ocean Coal Company purchased the nearby International Colliery and linked it to Garw. It then merged with the United National Company to become the Ocean and United National Collieries Limited. In 1943/5 the manager was still J. Breacher and this pit employed 567 men working underground in the Two-Feet-Nine and Three-Feet seams and 115 men working at the surface of the mine.

On Nationalisation in 1947, Garw Colliery was placed in the National Coal Board’s, South Western Divisions, No.2 Area, Afan Group, and at that time employed 116 men on the surface and 614 men underground working the Two-Feet-Nine and No.3 seams. The manager was still J. Breacher (he was still there in 1949) and the colliery had its own coal preparation plant (washery). It was working the same seams in 1954 but manpower had dropped to 115 on the surface and 554 men underground and the manager was now W.J. Mason.

In 1955, 297 men were employed at the coalfaces at this pit, this figure was 284 men in 1956 and 313 men working at the coalfaces in 1958. In 1954/55 this colliery was one of 42 that caused concern to both the NUM and the NCB over the high level of accidents. In 1961 it was still in the No.2 Area, Afan Group along with Ffaldau and International collieries. The total manpower of this Group was 1,905 men, while total coal production for that year was 446,898 tons. The Group Manager was V.C. Jones and the Area Manager was W.B. Cleaver. In 1969 this colliery was working the Two-Feet-Nine and Gellideg seams.

During the 1972 national strike over wages, the NUM Lodge at Garw withdrew safety cover against the orders of the Area and National Union. In 1969/75 the colliery manager was T, Clarke and in 1976 to at least 1981 it was J. Smith.

The coal board decided that due to the Garw and Ffaldau collieries working adjacent to each other, it would be more economical if they merged. This involved an underground roadway of 500 yards in length being driven to connect the collieries and all coal winding, manriding and supplies to go down the Garw shaft while the Ffaldau would be kept open for ventilation only. Garw Colliery was merged with Ffaldau Colliery in 1975 at a cost of £86,000, with Ffaldau’s output of coal brought up the Garw’s shafts.

Some of the fatalities at this mine:

- 19/2/1884, Richard Jones, aged 34, sinker, side of pit fell in.

- 29/05/1884, Richard DAVIES Age: 14 years, Oiler Struck by the wheel of the engine.

- 25/09/1886, John WILLIAMS, Age: 22 years, Occupation: Collier, Fall of clod.

- 17/05/1887, David GRIFFITH, Age: 43 years, Occupation: Ripper, Fall of the roof.

- 17/05/1887, William ROBERTS, Age: 26 years, Ripper. Fall of the roof.

- 12/06/1893, John JONES, Age: 21 years, Collier Fatally injured by a loaded tram which had been left standing on an inclined road running back wild into their stall but how it came to do so was not satisfactorily ascertained. There appeared to have been carelessness in the changing of the trams. 2 killed.

- 12/06/1893, David JONES Age: 18 years, Collier Colliery: Fatally injured by a loaded tram which had been left standing on an inclined road running back wild into their stall but how it came to do so was not satisfactorily ascertained. There appeared to have been carelessness in the changing of the trams. 2 killed.

- 12/06/1896 David JONES, Age: 73 years, Date: Occupation: Lamp station man, Struck by a piece of coal falling down the shaft.

- 31/05/1897, John BROWN Age: 40 years, Labourer Colliery: Crushed between trams he was standing between them tying some loaded material.

- 9/2/1910, David Llewellyn, aged 63, repairer, roof fall.

- 18/10/1910, Thomas DAVIES, Age: 43years, Labourer. Fall of the roof at working face where he was gobbing rubbish from a tram.

- 24/12/1910, William ATKINSON, Age: 19 years, Collier Fall of the roof at working face while he was cutting out an arm.

- 2/10/1913, Edwin DAVIES, Age: 48 years, Timberman Fall of side on roadway.

- 23/07/1914, Frank J BARWICK, Age: 15 years, Collier boy Fall of the roof near the face of working place, as he was filling coal into a tram.

- 9/02/1910, David LLEWELLYN, Age: 63 years, Repairer. Fall of side on road.

- 23/11/1910 DJ MORGAN Age: 28 years, Haulier. Fell off the gun and was run over by a tram.

- 14/12/1912, John REES Age: 62 years, Occupation: Haulier. Struck and fatally injured by detached haulage rope, the chain of which had caught in moving trams. He died January 9th,

- 2/10/1913, Edwin DAVIES, aged 48, timberman, roof fall.

- 17/12/1913, David OWEN, Age: 46 years, Collier, as he was walking in front of a horse and tram, his light went out, he stopped to the side of the road but was crushed by the passing trams. He died on December 20th 1913.

- 9/06/1914, James R SAPPELL Age: 16 years, Colliers asst. Fall of the roof at the face from unseen slants.

- 23/7/1914, Frank J. Barwick, aged 15, collier boy, roof fall.

- 16/07/1928, David TUDOR, Age: 43 years, Occupation: Pitman Cleaning gearheads and examining shaft and had descended 239 yards to landing when the curb 35yds from the top gave way killing him. 1 killed 1 injured

Some Statistics:

- 1889: Output: 164,134 tons.

- 1894: Output: 196,848 tons.

- 1896: Manpower: 540.

- 1899: Manpower: 363.

- 1900: Manpower: 367.

- 1901: Manpower: 493.

- 1902: Manpower: 513.

- 1903: Manpower: 547.

- 1905: Manpower: 730.

- 1907: Manpower: 704.

- 1908: Manpower: 781.

- 1909: Manpower: 781.

- 1910: Manpower: 847.

- 1911: Manpower: 831.

- 1912: Manpower: 700.

- 1913: Manpower: 756.

- 1915: Manpower: 700.

- 1916: Manpower: 700.

- 1918: Manpower: 607.

- 1920: Manpower: 700.

- 1922: Manpower: 700.

- 1923: Manpower: 767.

- 1924: Manpower: 734.

- 1925: Manpower: 749.

- 1927: Manpower: 861.

- 1928: Manpower: 931.

- 1929: Manpower: 931.

- 1930: Manpower: 880.

- 1931: Manpower: 700.

- 1932: Manpower: 670.

- 1933: Manpower: 714.

- 1935: Manpower: 691.

- 1937: Manpower: 760.

- 1938: Manpower: 744.

- 1940: Manpower: 680.

- 1941: Manpower: 760.

- 1942: Manpower: 500.

- 1944: Manpower: 540.

- 1945: Manpower: 692.

- 1947: Manpower: 730.

- 1948: Manpower: 727. Output: 150,000 tons.

- 1949: Manpower: 699. Output: 150,000 tons.

- 1950: Manpower: 669.

- 1953: Manpower: 661. Output: 185,000 tons.

- 1954: Manpower: 669. Output: 190,000 tons.

- 1955: Manpower: 608. Output: 177,150 tons.

- 1956: Manpower: 601. Output: 168,174 tons.

- 1957: Manpower: 629. Output: 166,243 tons.

- 1958: Manpower: 632. Output: 165,439 tons.

- 1960: Manpower: 669. Output: 161,491 tons.

- 1961: Manpower: 669. Output: 170,649 tons.

- 1964: Manpower: 702.

- 1969: Manpower: 685.

- 1970: Manpower: 681.

- 1971: Manpower: 678.

- 1972: Manpower: 683.

- 1974: Manpower: 840 Output: 367,000 tons.

Information supplied by Ray Lawrence and used here with his permission.

Return to previous page