Tredegar, Sirhowy Valley, (16210461)

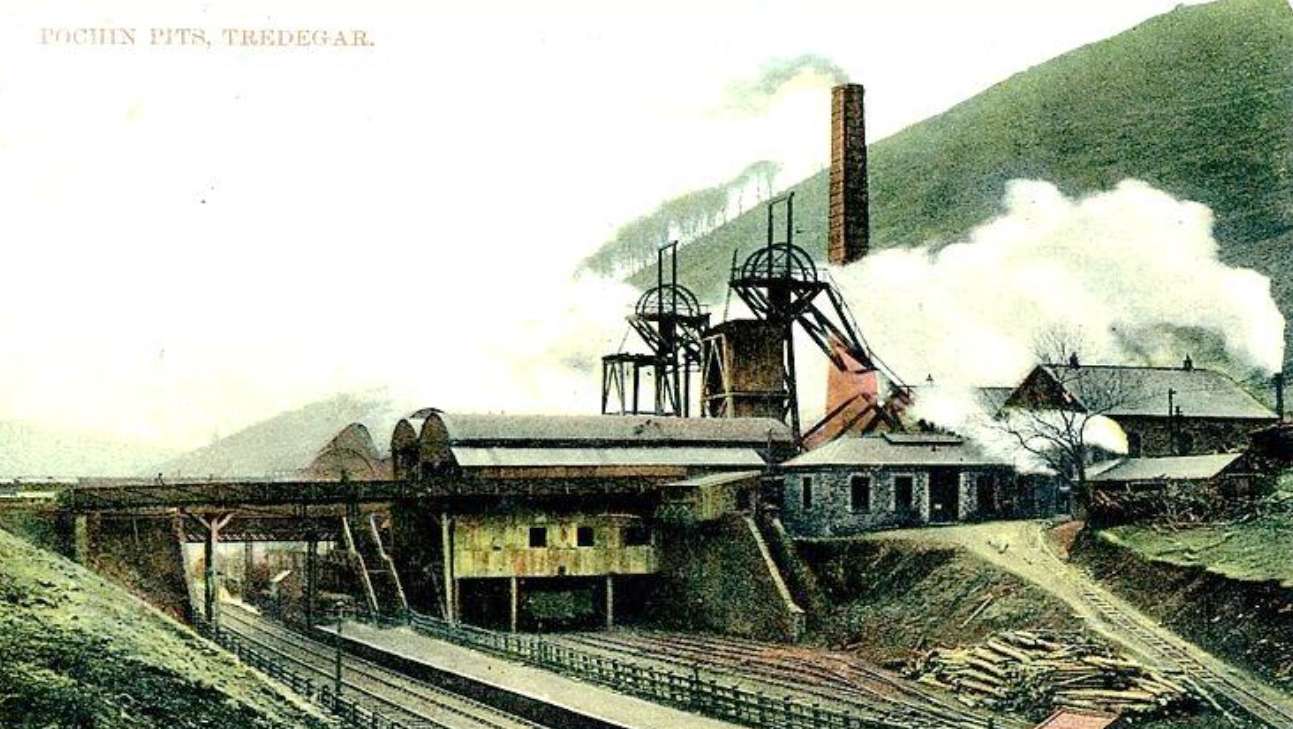

This colliery was approximately three miles to the south of Tredegar and was named after Henry Davis Pochin, a director of the Tredegar Iron and Coal Company, the first sod for the sinking of the pits was cut in May 1876 by his daughter, Laura Pochin, who later married a future chairman of the company to become Lady Aberconway. It had a mineral take measuring 3,200 yards north to south and 2,000 yards east to west. It was served by the Sirhowy Branch of the London, Midland and Scottish Railway. For some reason or other sinking was abandoned until 1880, it was then completed in ten months to a depth of 340 yards, with the first coal being raised in 1881 and the Yard seam being fully worked in 1883. On the 6th of June 1881, the newspapers reported that:

This colliery was approximately three miles to the south of Tredegar and was named after Henry Davis Pochin, a director of the Tredegar Iron and Coal Company, the first sod for the sinking of the pits was cut in May 1876 by his daughter, Laura Pochin, who later married a future chairman of the company to become Lady Aberconway. It had a mineral take measuring 3,200 yards north to south and 2,000 yards east to west. It was served by the Sirhowy Branch of the London, Midland and Scottish Railway. For some reason or other sinking was abandoned until 1880, it was then completed in ten months to a depth of 340 yards, with the first coal being raised in 1881 and the Yard seam being fully worked in 1883. On the 6th of June 1881, the newspapers reported that:

The sinking operations at Pochin Colliery near Hollybush, are rapidly nearing completion. At a depth of 298 yards the men came last week on a seam of coal 6ft, 8in. thick. They have now reahed a depth of 308 yards, and anticipate getting through the celebrated vein of steam coal when about a dozxen yards further down. A good road is to be made between Darran and Tredegar to meet the traffic which the opening of the new colliery will create.

In 1888 it was working the Big and Yard seams.

The North Pit or No.2 Pit was the downcast ventilation shaft and was 18 feet in diameter with the winding depth being 316 yards to the yard seam. The winding capacity was for two trams per wind. The wooden head frame was replaced in 1920 by a lattice steel one made by Messrs. Rees & Kirby. It was 78 feet to the centre of the sheaves, with the sheaves being 16 feet in diameter.

The winding engine cylinders were 30 inches in diameter was a stroke of 72 inches and of the drop valve type. The drum was 16 feet in diameter and made by Markham and Company. The South or No.1Pit was 16 feet in diameter with the winding depth being 437 yards to the Old Coal seam. It took one minute to wind two trams of coal. The old wooden headgears were replaced by steel ones in 1924 that were 78 feet high to the centre of the sheaves. It was made by Norton Harty & Company. The winding engine for this pit had 30-inch diameter, 72-inch stroke valves with Corliss valve gear and a semi-conical drum, 12 feet to 18 feet in diameter. The cylinders were replaced in 1932. The original boiler plant was replaced from the 1920s with Nos. 1 to 5 being installed in 1924, Nos. 7 and 8 in 1937 and Number 9 in 1939.

Ventilation was originally by a Guibal type fan which was installed in 1881; it was 40 feet in diameter and 12 feet wide. This was followed by a Waddle type fan of 25 feet diameter that was steam driven, and in the 1940’s, another Waddle fan that was electrically driven and 15 feet in diameter. The manager in 1888 and 1896 was W.H. Rouledge and in 1900/19 it was T. Reynolds. In 1888 Pochin Colliery worked the Big Vein (Four-Feet) and Yard seams, and in 1897 a coal washing plant was installed at the surface of the pit. On the 29th of June 1911, the AGM of the TIC reported that the Upper Rhas Las seam had been developed at Pochin and was turning out satisfactory, and a price list had been arranged there. Both the Upper and Lower Rhas Las seams underlay the whole of the Pochin ‘take’ and would generate a good income in the future.

By 1913 the colliery employed 1,693 men, with the Tredegar Company advertising in that year:

Tredegar, McLaren Merthyr, Tredare Merthyr, Best Welsh Steam Coal. of Great Efficiency. Large Size. Thoroughly Screened and Cleaned. Supplied to British Admiralty and Foreign Governments Used for Trial Runs of H.M. Battleships. Tredegar a Locomotive Coal of the Highest Quality Speciality For Bunkers -Washed Nuts & Peas. Shipping Ports: Cardiff Barry, Newport and Penarth. Tredegar Iron & Coal Company Ltd., London -60, Fenchurch Street. Cardiff-The Exchange

In 1927 the manager was H. Evans. In 1935 Pochin Colliery was the largest of the TIC’s collieries, employing 1,409 men underground and 166 men on the surface producing 420,000 tons of coal. In 1937 a washery was erected on the surface of this mine that could handle 100 tons of coal per hour. In 1938 the manager was A.F. Williams and in 1945 B.L. Phillips. In the 1940s the screening plant consisted of three coal tumblers tipping the coal onto three picking belts that were fitted with jigging screens. The full trams gravitate from both the pits to the creepers and are weighed at the top of the creepers and onto the tumblers. They then gravitate back to the pit top. The fitting shop was fitted with a lathe, drilling and screwing machines and a saw. The Smith’s shop had four fires and a steam hammer. There were also carpenters, electricians and tram repair shops plus a sawmill. The washery had a capacity to wash 100 tons of coal every hour.

The Lamp room could accommodate 1,400 electric hand lamps and 200 flame safety lamps. At that time there were 900 Oldham-type electric hand lamps, 54 Oldham electric cap lamps and 180 flame safety lamps in use. The inlet sidings had a capacity of 220 waggons and the outward sidings could hold 120 full waggons. The underground haulages consisted of; one 200 hp, two,150 hp, five, 100 hp, one 75 hp and one 55 hp electric types plus numerous compressed air and electric types under 50 hp. It pumped up the pit an average of 61,026 gallons of water per day. In 1943 this pit employed 732 men working underground in the Meadow Vein, Big Vein, Old Coal, Lower Rhas Las and Upper Rhas Las seams and 162 men on the surface of the mine.

In 1944 a canteen funded by the Miners’ Welfare Committee was opened. On Nationalisation of the Nation’s coal mines in January 1947, Pochin Colliery was placed in the National Coal Board’s, South Western Division’s, No.6 (Monmouthshire) Area, Tredegar Group, and at that time employed 181 men on the surface and 711 men underground working the Meadow Vein (Yard/Seven-Feet, Old Coal (Five-Feet/Gellideg), and Upper Rhas Las (Upper-Nine-Feet) seams. The manager was still B.L. Phillips.

In 1950 the NCB estimated that the reserves of coal at this colliery were

- Polka seam: 244,000 tons.

- Rhas Las: 350,000 tons.

- Meadow Vein: 2,204,000 tons.

- Total: 2,798,000 tons.

The report continued to state that:

at present the Polka and Meadow Vein are worked but the Polka will; be exhausted by the end of 1952, after which production will be confined to the Meadow Vein.

It also commented that:

a very large portion of this seam is unworkable.

At this colliery the Old Coal seam consisted of 32 inches of coal, the Meadow Vein was, top coal 9 inches, clod 39 inches, coal 20 inches, the Polka or Upper Black Vein seam is absent while the Rhas Las is 25 inches thick. The Big Vein group of coals show, from the top; Big Vein coal 66 inches, mine ground 34 feet, Yard Coal 43 inches, mine ground 17 feet 11 inches, Three-quarter seam 26 inches. Elled seam 22 inches.

In 1954/55 this colliery was one of 42 that caused concern to both the NCB and the NUM over the high level of accidents. By 1954 manpower had dropped to 149 men on the surface and 544 men underground and was by then working the Meadow Vein, Three-quarter and Upper Rhas Las seams. The manager was W.J. Evans. In 1956 out of the total colliery manpower of 698 men, 306 of them worked at the coalfaces, this coalface figure dropped to 285 men in 1958 and in 1961 out of the total colliery manpower of 538 men, 197 of them worked at the coalfaces. In 1961 this colliery was still in the No.6 Area’s, Tredegar Group along with Markham’s Navigation, Oakdale Navigation and Waterloo collieries. The total manpower for this Group was 3,769 men, while the total coal production for that year was 955,566 tons, making it one of the largest Groups in terms of manpower and production in the South Wales Coalfield.

On the 17th of October 1962, Brinley Leath, aged 57 years was rescued after being trapped under a fall of roof for almost 12 hours. An hour later the body of John Driscoll, aged 21 years, was recovered from the same fall of about fifty tons.

In May 1964 the NCB agreed to the NUM request to drift down to the Garw seam in an attempt to avoid closure. The Garw seam proved to be 29 inches thick, and according to the NUM workable, but according to the NCB not. The NUM then asked for a further drivage to explore the seam, and the NCB agreed on the condition that in the meantime the men (411) were transferred to Markham and Oakdale. The drivage was a failure and Pochin Colliery was closed on the 25th of July 1964.

The Pochin coals consisted of Rank 301a prime coking coal with a volatile matter of 19.6 to 27.5 d.m.m.f.%. The coal measures succession is thin in this area and all the workable seams of the Lower and Middle Coal Measures were readily accessible. The general mining conditions were good since there was an absence of major compressional structures and the dips of the strata are generally low and fairly steady.

An explosion occurred at 9 pm on Saturday 8th of November 1884 about 300 yards from the pit-bottom killing 14 miners who were carrying out repairs at the pit. The full report can be found here.

Some of the others that died at this mine:

- 14/06/1881, J. Price, Age: 34: Sinker: Fell out of bowk when about 40 yards from the bottom. He was alone in the bowk, and there was nothing to show what caused him to fall out.

- 28/08/1882, Edwin Williams, Age: 36: Collier: Injured by a fall of stone, and died on September 19th.

- 4/04/1885, John Hughes, Age: 22: Collier: Fall of coal. The top coal was standing supported by timber he knocked the timber out just before leaving expecting the coal to fall by the morning, but afterwards, he went back and began to work some more underneath when it fell.

- 2/09/1886, Noah Hughes Age: 37: Collier: Fall of stone. While holing in the big vein the top fell on him.

- 25/10/1886, Thomas Yates, Age: 13: Collier: Fall of stone.

- 6/08/1887, John Stevens, Age: 21: Haulier. A piece of coal falling from the surface rebounded from the shaft side and struck him near the eye.

- 17/08/1887, George Hood, Age: 14: Colliers boy: Fall of coal and clod while filling coal near the face of the working place, where he was engaged with his brother.

- 7/09/1887, Thomas Hughes Age: 20: Fall of the roof at the face of his working place in consequence of slips and not having sufficient timbers set.

- 25/11/1887, John Bevan, Age: 20: Collier: Fall of the roof in his working place

- 3/04/1888, David Jones, Age: 41: Collier: Fall of the roof from slips at the face of his stall.

- 7/08/1888, Thomas Pratten, Age: 48: Collier: Fall of the roof on the side of his stall road when knocking out props from under it. He seems to have stood in the wrong place to knock them out.

- 20/08/1888, Isaac Jenkins, Age: 19: Collier: Fall of the roof from slips. The place was not well propped considering the nature of the roof there. 2 killed.

- 20/08/1888, Joseph Powles, aged 12: Fall of roof from slips. The place was not well propped considering the nature of the roof there. 2 killed.

- 15/04/1890, George Taylor, Age: 19: Collier, A piece of overhanging clod and coal fell over the sprags which were set and rolled against him as he was on the floor pushing a large stone

- 2/05/1890, George Taylor, Age: 19: Collier: As shot firing is only done when the persons ordinarily employed are out of the mine at night or between shifts this man and his comrade had prepared a shot in the roof where ripping was required and having gone distance on their way out Taylor turned hack to fetch a shovel and passing under the stone which they intended blasting it fell upon him.

- 27/07/1892, Aaron Lloyd, Age: 23: Haulier: Fall of roof rubbish over timbers in a stall road. The horse may have interfered with some of the props

- 25/08/1892, Thomas Barnard McGraith, Age: 20: Repairer: One of two trams which the haulier was taking up a rise heading became uncoupled and running back met him while walking up and caused his death.

- 10/01/1894, Alfred Moon, Age: 46: Repairer: Fall from the side of a rubbish stall where he was unloading a tram. The stone appears to have rolled down more or less and to have squeezed him against the side of the tram over which he was leaning at the time. He does not seem to have thought much about it at the time and did not report it before leaving the colliery but on arrival home complained of pain in the bowels which continued till his death the following evening.

- 3/05/1894, William Williams, Age: 27: Collier: He was an experienced haulier it seems and stated as such when required. He forgot that at a certain point on the road, there were some low timbers and when riding out on the horse chain his head was crushed between the loaded tram and these timbers.

- 4/10/1894, Thomas Lloyd, Age: 50: Airwayman: Engaged with another man on an air road he considered a piece of roof unsafe and commenced to pull it down. The stone ripped further back than he expected and part of it fell upon him causing injuries from which he died 6th. He had worked many years in collieries and for upwards of four in this pit.

- 25/01/1896, William Lloyd, Age: 24: Collier: Fall of coal from the face

- 7/02/1896, Edward Sanders, Age: 30: Collier: While removing loose stone after a shot a large stone from the roof which had probably been loosened by the shot fell on him.

- 21/08/1896, Matthew Matthews, Age: 42: Collier: Fall of overhanging clod

- 25/03/1897, Thomas Williams, Age: 41: Collier: Crushed through an error of judgement by a fall of the roof from slips at his workplace. The roof in this part of the workings abounds in these slips and is very treacherous. It is to be hoped that it will soon alter meanwhile great care is needed.

- 8/11/1897, George Baylis, Age: 28: Collier: Crushed by a fall of side in a road

- 6/12/1897, John Griffiths, Age: 58: Night examiner: While making his second inspection in one of the main headings, a fall of the side took place and fractured his thigh. He died on the 21st December from the injuries. There have been several accidents in the roadways, which should not be the case.

- 27/09/1898, Thomas Prosser, Age: 37: Haulier: Crushed when bringing a full tram along a stall road he appears to have fallen in front of it. When found he was dead and lying across the road in front of the tram to which the horse was attached and standing quite.

- 8/10/1898, James Evans, Age: 41: Hitcher: Killed instantly by a piece of coal falling down the shaft from the tram which was being banked at the surface.

- 10/2/1899, Benjamin Williams, Age: 19: Collier: Was killed on his way from work at the colliery, by getting out of a train on the L.& N W while it was in motion.

- 9/05/1899, S William Davies, Age: 38: Collier: Fall of overhanging clod in his stall road

- 5/04/1910, Edward Leigh, Age: 35: Shackler: He stumbled in front of a full tram and he and another man were brought forward to the shaft to hitch on the cage and were fatally injured.

- 6/10/1910, Ivor Jenkins, Age: 23: Collier: Fall of the roof at the working face from two converging slips.

- 19/12/1910, D.J. Samuel, Age: 29: Collier: Fall of the roof at the working face.

- 26/06/1911, Cornelius Curtin, Age: 47: Timberman: Fall of side on the road while re-timbering it.

- 8/06/1912, Stephen James, Age: 20: Colliers butty: Fall of the side at the working face. When holing in the bottom coal a piece of top coal discharged a post and fell upon him.

- 12/02/1913, Augustus Morgan, Age: 35: Pitman: Fell off cage into the sump

- 29/09/1925, Albert Watkins, Age: 34: Collier: Fall of the roof. Died 14th October.

- 23/11/1928, Ronald Leslie Worley, Age: 16: Colliers helper: Fall of the roof. Died 24th November.

Some Statistics:

- 1889: Output: 170,317 tons.

- 1894: Output: 296,000 tons.

- 1896: Manpower: 1,029.

- 1899: Manpower: 767.

- 1900: Manpower: 1,151.

- 1901: Manpower: 1,140.

- 1902: Manpower: 1,152.

- 1903: Manpower: 1,077.

- 1905: Manpower: 1,216.

- 1907: Manpower: 1,323.

- 1908: Manpower: 1,550.

- 1909: Manpower: 1,550.

- 1910: Manpower: 1,696.

- 1912: Manpower: 1,629.

- 1913: Manpower: 1,693.

- 1915: Manpower: 1,596.

- 1916: Manpower: 1,224.

- 1918: Manpower: 1,336.

- 1919: Manpower: 1,234.

- 1920: Manpower: 1,495.

- 1923: Manpower: 2,252.

- 1924: Manpower: 2,370.

- 1925: Manpower: 2,220.

- 1926: Manpower: 2,030.

- 1927: Manpower: 1,771.

- 1928: Manpower: 1,765.

- 1930: Manpower: 1,286.

- 1931: Manpower: 1,387.

- 1932: Manpower: 1,600.

- 1933: Manpower: 1,590.

- 1934: Manpower: 1,532.

- 1935: Manpower: 1,575. Output: 420,000 tons.

- 1937: Manpower: 1,468.

- 1938: Manpower: 1,345.

- 1940: Manpower: 1,342.

- 1944: Manpower: 1,342.

- 1945: Manpower: 894

- 1947: Manpower: 892.

- 1948: Manpower: 849. Output: 178,215 tons.

- 1949: Manpower: 861. Output: 180,000 tons.

- 1950: Manpower: 777.

- 1951: Manpower: 800. Output: 166,400 tons.

- 1953: Manpower: 759. Output: 225,000 tons.

- 1954: Manpower: 693. Output: 152,000 tons.

- 1955: Manpower: 731. Output: 137,546 tons.

- 1956: Manpower: 698. Output: 140,696 tons.

- 1958: Manpower: 646. Output: 116,356 tons.

- 1960: Manpower: 582. Output: 92,566 tons.

- 1961: Manpower: 538. Output: 92,098 tons.

- 1962: Manpower: 542.

Information supplied by Ray Lawrence and used here with his permission.

Return to previous page