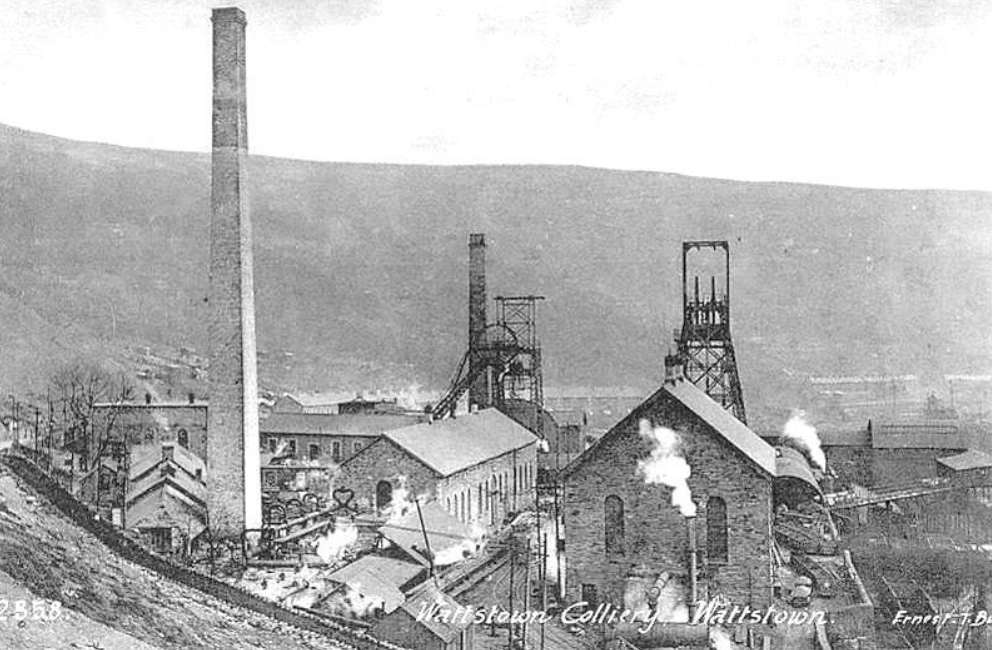

Wattstown (ST 0207 9376)

The mineral lease for this colliery was agreed in October 1881 between the landowners, Crawshay Bailey and William Partridge Bailey, and Ebenezer Lewis, Henry Lewis and Matthew Cope who went on to sink the Nos.1 and 2 pits.

The mineral lease for this colliery was agreed in October 1881 between the landowners, Crawshay Bailey and William Partridge Bailey, and Ebenezer Lewis, Henry Lewis and Matthew Cope who went on to sink the Nos.1 and 2 pits.

The No.1 (downcast ventilation shaft) was 17 feet 6 inches in diameter and 454 yards deep to the Six-Feet seam although coal winding was from 425 yards deep at the Four-Feet seam level. The No.2 (upcast ventilation shaft) was 14 feet in diameter and 454 yards deep to the Six-Feet seam. They were 27 yards apart. In 1894 this pit was deepened to the Lower-Five-Feet seam at a depth of 555 yards. There then follows a confusing array of individuals and companies who came to control the pit. The Lewis and Matthew Cope were followed by Messrs. Griffiths and Company, who was followed by Messrs. Watts, Watts and Company, who became the National Steam Coal Company in 1887, who became the National Collieries Company Limited and then became the United National Steam Coal Company Limited which became a public liability company in 1893.

In September 1884 the manager instructed the ventilation fan driver on the night shift to count the revolutions that the fan completed (the Company had not installed a mechanical counter as this meant that the pit would have to stop while the job was being done) entering in a book every hour the revs per minute. This averaged out to 45 rpm up to one o’clock when the nightshift overman underground noticed that the airflow was defective, up he went to the fan house and found the attendant fast asleep “sitting on a window, his hands on his face and asleep.” The attendant was fined 20 shillings in a magistrates court. Although he placed the men’s lives in danger in this gaseous mine, you must feel some sympathy for the man, counting the turn of a wheel must be akin to counting sheep, especially at night!

In 1887 the pit was only working the Four-Feet seam which they found was lying almost vertical and virtually fault-free, it was semi-bituminous and one of the best steam coals. A drawback was that the mine was very dusty and the roof was friable leaving it prone to give off large amounts of methane. The pit was worked on the old style longwall and by that time 170 acres of the Four-Feet seam had been worked the workings extending 1,000 yards to the north, 600 yards south and 600 yards east. To the west of the shafts, no work had been done. Coal production was on the day shift with repairing and other work on the night shift which was between 7 p.m. and 4.30 a.m. The face roads were 7 feet high and 9 feet wide with a soft clod of 6 to 18 inches that lay above the coal also taken down so that roof supports could be erected in solid ground, despite this the weight of the roof pushed the height of the roads down to about 5 feet around 100 yards behind the face and repairing of the roadways had to be done. All the men carried flame safety lamps but naked lights were allowed at the downcast pit-bottom although the pit bottoms and haulages were lit by electric lights.

The colliery hit the news in May 1893 when rumours abounded about the trades union committee acting on their own authority and not carrying out the men’s wishes. Management had dismissed the ‘wrongdoers’ and the union set up an investigation committee to look at the affair. They found that the committee had sent in letters to the union’s office contradicting the wishes of the men, particularly in calling for the resignation of the President, William (Mabon) Abraham. They also discovered that £242 had been illegally withdrawn from a bank account. The old committee was replaced by a new one.

The colliery which was locally called ‘Cwtch’ was deepened in 1894 by another 101 yards to make available all the steam coal seams of the Middle and Lower Coal Measures. The manager in 1893 was G.W. Wilkinson, in 1896 it was William Meredith and in 1908 it was John Kane and in 1915/19 it was Rees Morgan. In 1923/7 the manager was J.S. Vincent while in 1930 it was managed by Evan Evans. Amongst other seams, it extensively worked the Five-Feet seam at a thickness of between 50 inches to 75 inches. The middle and Upper Seven-Feet seams were worked together extensively at a thickness of between 40 inches to 59 inches. It was known locally as the No.2 Seam. The Gellideg seam was worked at a thickness of 54 inches. The Four-Feet seam, which was called the Two-Feet-Nine seam in this area was a 9 feet 10 inches thickness of coal and dirt.

By 1905 both shafts were used for coal winding; the coal from the Two-Feet-Nine and Four-Feet seams was brought up the downcast shaft. It was intended to deepen this shaft to the Lower-Five-Feet seam in the near future.

It was served by the Taff Vale Railway and had a sidings capacity of; 161 full wagons, 261 empty wagons and 67 other wagons. In 1906 this colliery installed an underground 250 h.p. electric haulage that hauled trams for a distance of 1,800 yards at 9 miles per hour. In 1914 a new Waddle type ventilating fan was installed with a diameter of 12 feet.

In 1913 National Colliery was managed by E.D. James and employed 1,248 men. In1915 the Business Statistics Company’s book ‘South Wales Coal and Iron Companies’ described the United National Collieries Limited as; “the properties comprise the Risca (New and Old) Black Vein Collieries, Risca, Monmouthshire, the National Colliery, Wattstown, Rhondda, Glamorganshire, and the Standard Colliery (purchased in August 1914).”

The Company’s collieries were valued at £491,922 with a share value of £1,020,689. Between 1903 and 1914 the Company made a profit of £1,049,845. The board of directors was; Fenwick Shadforth Watts, Chairman, Sydney King George, Edgar Watts, Colonel Alex Keith Wyllie, Herbert Sanders Sanders-Clark, Stanley Hilson Burgess, James Miles, J.A. Jones and Ivor Llewellyn. In 1926 United National Collieries was purchased by the Ocean Coal Company which retained control of the pit until Nationalisation in 1947. In 1934 the directors of United National Collieries were Lord Davies, Thomas Evans, William Phillip Thomas, Alexander Jaffray Cruikshank, Alfred Ernest Yarrow, Herbert Frank Perkins, Sir Henry Webb and Michael Arthur Henderson. The company secretary was A.W. Dalton. At that time it controlled three collieries that employed 3,277 men who produced 1,750,000 tons of coal.

In 1935 National Colliery employed 276 men on the surface and 1,192 men underground the manager at that time was Evan Evans, while in 1943/5 the manager was W.P. Bundy. In 1943 this pit employed 551 men working underground in the Nine-Feet, Five-Feet and Six-Feet seams and 211 men working at the surface of the mine.

On Nationalisation of the Nation’s coal mines in 1947, National Colliery was placed in the National Coal Board’s, South Western Division’s, No.3 Area, No.1 Group, and at that time employed 190 men on the surface and 594 men underground, with the South pit working the Six-Feet seam, and the North pit the Red Vein, Six-Feet and No.2 seams. The colliery had its own coal preparation plant (washery) and the manager was still W.P. Bundy.

In December 1949 the Coal News reported that ten men retiring from National Colliery shared over 500 years of working underground. Alf Davies of John Street, Ynishir, was ten years of age when he started underground as a doorboy at 17 shillings a fortnight. He would have retired ten years earlier but stayed on due to the war. William Meade was 75 years old and had worked 63 years as a miner, the others were Edward Pike, William Phillips, Sam Buttle, George Gready, John Jones, Morgan Thomas, Evan Evans and Fred Desmond.

In 1954 this colliery employed 186 men on the surface and 603 men underground working the Bute, Yard and Upper-Seven-Feet seams. The manager was now E. Withey.

In 1955 the NCB announced the development of the Six-Feet, Nine-Feet and Five-Feet seams under the Penrhys area which it claimed would give this colliery thirty years of work. In 1954 out of the total colliery manpower of 741 men, 375 of them worked at the coalfaces, in 1956 the coalface figure was 389 men, in 1957 it was 381 men, and in 1958, 352 men worked at the coalfaces. The three feet thick No.1 Seam had a price list of two shillings and two pence per square yard for hand cutting and one shilling and eleven pence per square yard for machine cutting in a three feet high seam.

In 1968 the National Union of Mineworkers Lodge at National Colliery complained bitterly over the rundown of the colliery which resulted in poor working conditions and the lack of roof supports, this was all to no avail for it closed on November 23rd of that year.

Based on the Nine-Feet seam this colliery produced types 203 and 204 Coking Steam Coals, both types were low volatile, with the 203 being weak to medium caking, and the 204 being medium to strong caking. The ash content for both types was in line with the rest of the Coalfield at between 5% to 9%, with the sulphur content also conforming to the Coalfield norm at between 0.6% to 1.5%. The uses for these coals varied from steam raising in boilers for ships, locomotives, power stations etc., to foundry and blast furnace cokes, to coking blends.

There were two major explosions at this colliery and a full report on each can be found on the relative pages; 39 miners were killed in 1887, and 119 miners were killed in 1905.

Some Statistics:

- 1889: Output: 255,919 tons.

- 1894: Manpower: 1,118. Output: 311,271 tons.

- 1896: Manpower: 1,092.

- 1899: Manpower: 1,066.

- 1900: Manpower: 1,207.

- 1901: Manpower: 1,128.

- 1903: Manpower: 1,291.

- 1908: Manpower: 1,394.

- 1909:Manpower;1,394.

- 1910: Manpower: 1,246.

- 1911: Manpower: 1,241.

- 1912: Manpower: 1,372.

- 1913: Manpower: 1,248.

- 1915: Manpower: 1,248.

- 1916: Manpower: 1,248.

- 1918: Manpower: 1,104.

- 1919: Manpower: 1,028.

- 1920: Manpower: 1,150.

- 1922: Manpower: 1,269.

- 1923: Manpower: 1,499.

- 1924: Manpower: 1,447.

- 1925: Manpower: 1,475.

- 1926: Manpower: 1,423.

- 1927: Manpower: 1,568.

- 1928: Manpower: 1,656.

- 1929: Manpower: 1,600.

- 1930: Manpower: 1,627.

- 1931: Manpower: 1,440.

- 1932: Manpower: 1,420.

- 1933: Manpower: 1,370.

- 1935: Manpower: 1,468.

- 1937: Manpower: 1,055.

- 1938: Manpower: 777.

- 1940: Manpower: 1,000.

- 1941: Manpower: 1,340.

- 1942: Manpower: 940.

- 1945: Manpower: 772.

- 1947: Manpower: 741.

- 1948: Manpower: 770. Output: 220,000 tons.

- 1949: Manpower: 810. Output: 210,000 tons.

- 1950: Manpower: 840.

- 1953: Manpower: 763. Output: 220,000 tons.

- 1954: Output: 184,000 tons.

- 1955: Manpower: 741. Output: 168,484 tons.

- 1956: Manpower: 742. Output: 162,682 tons.

- 1957: Manpower: 793. Output: 152,281 tons.

- 1958: Manpower: 720. Output: 211,779 tons.

- 1959: Manpower: 633. Output: 197,416 tons/

- 1960: Manpower:585. Output: 203,162 tons.

- 1961: Manpower: 632. Output: 191,734 tons.

- 1962: Manpower: 496. Output: 158,979 tons.

- 1963: Manpower: 540. Output: 128,312 tons.

- 1964: Manpower: 546. Output: 129,493 tons.

- 1966: Manpower: 605. Output: 123,475 tons.

Information supplied by Ray Lawrence and used here with his permission.

Return to previous page