Deri, Darran Valley (12070294)

This colliery was located at both the top end of the Darran Valley and the top end of Caerphilly County Borough Council, settling in between Deri and Fochriw. Its mineral take was curtailed by the Pengam and Penydarrengeological faults to the east, old Fochriw and Bedlinog workings to the north and west, and the Elliots and Groesfaen workings to the south.

This colliery was located at both the top end of the Darran Valley and the top end of Caerphilly County Borough Council, settling in between Deri and Fochriw. Its mineral take was curtailed by the Pengam and Penydarrengeological faults to the east, old Fochriw and Bedlinog workings to the north and west, and the Elliots and Groesfaen workings to the south.

The sinking of this mine was started in 1919 by the Powell Duffryn Steam Coal Company Limited, making this the last large colliery to be sunk by this Company. The first coal was raised in 1923. The South Pit was sunk to the Five-Feet/Gellideg seam which it found at a depth of 566 yards (501 metres). It encountered the No.2 Rhondda seam at a depth of 137.3 metres, the Four-Feet seam at a depth of 406 metres, and the Nine-Feet seam at a depth of 454.2 metres. Coal was also wound in this shaft which had two single-decked carriages each capable of carrying two trams.

The Lower-Four-Feet seam had a section of 0.75 metres, the Upper-Four-Feet seam was one metre thick and the Yard seam had a thickness of 0.45 metres.

The North Pit was sunk to a depth of 483 yards. This was the main winding pit with the coal wound from the Red Vein level. The shaft was equipped with two double-decked carriages with each deck carrying two trams. Both shafts were 20 feet in diameter. The main seams to have been worked at this pit were the Upper-Four-Feet and Rhas Las (Nine-Feet). Based on the Nine-Feet seam this colliery’s coals were classed as type 203 Coking Steam Coal, low volatile, weak to medium caking, with an ash content of around 5% to 9%. These coals were used for steam raising in boilers for ships, locomotives, power stations etc., and for foundry and blast furnace coke.

Ventilation was by a Walker type fan that was 18 feet 6 inches in diameter and 7 feet 6 inches wide, which was driven by 475hp motors. It was installed in 1922 and gave an airflow of 250,000 feet per minute. Towards the end of its working life58,000 gallons of water, every hour was pumped up the shafts.

The U.S. ambassador to Britain used to make an annual report on the state of the South Wales Coalfield and in his 1922 report he stated:

During the past year, substantial progress has been made with the sinking of the two new Ogilvie pits at Deri, and the coal has been reached. Before the end of 1923, a substantial output will be made and a considerable number of men will be employed. It will be worked with electricity and compressed air from Bargoed, both supplies have been in operation for some time. The shafts are lined with concrete, this being an innovation so far as the Powell Duffryn Company is concerned…the installation of the latest methods of machine mining has been introduced into the valley by the Powell Duffryn Co., and coal cutters and conveyors are now the means adopted for working the measures. A great deal of prejudice had to be overcome, particularly among the older colliers, but it is now generally agreed that the conveyor system is both less arduous and safer than the old methods. An additional advantage is that seams hitherto considered unworkable because of their thinness can be exploited and a far greater amount of rubbish can be stowed underground, thereby releasing the pits to a great extent and allowing them to wind coal in place of rubbish.

In 1935 this colliery employed 150 men on the surface and 930 men underground with the manager being A.T. Minhinnick (he was there in 1927). In 1938 the manager was W.H. Knibbs and this pit employed 1,011men underground and 225 men on the surface. In 1943 the manager was T. Carthew and this pit employed 773 men working underground in the Yard, Red, Upper and Lower Four-Feet and Rhas Las seams and 194 men working at the surface of the mine.

On Nationalisation in 1947, Ogilvie Colliery was placed in the National Coal Board’s, South Western Division’s, No.5 (Rhymney) Area, Group No.1, and at that time employed 184 men on the surface and 778 men underground working the Upper-Four-Feet and Rhas Las seams. The manager was P.C. Parry and in 1949 it was R. Brockett.

By 1954 manpower had increased to 178 on the surface and 933 men underground working the Yard, Upper and Lower Four-Feet and Rhas Las seams. With the manager now being M.L. Southwood-Jones.

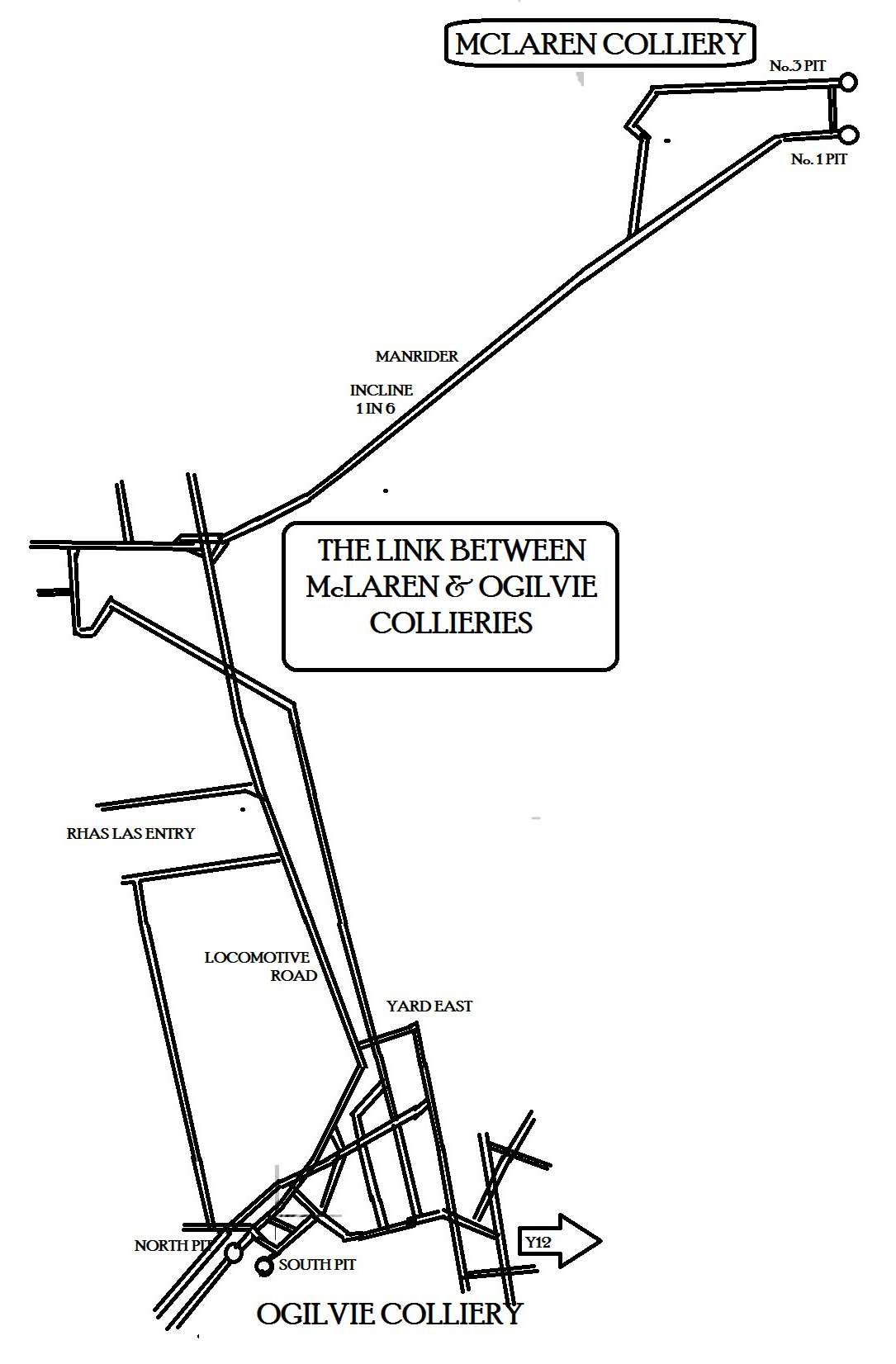

In 1955 out of the total colliery manpower of 997 men, 435 of them worked at the coalfaces, in 1956 the coalface figure was 476 men, and in 1961 out of the total colliery manpower of 1,425 men, 556 of them worked at the coalfaces. In 1957 this colliery was the centre of a major reconstruction scheme costing £5 million, with 300 contractors employed on the surface of the mine modernising facilities. A new pit bottom, fifty yards higher, was made in the North Pit and a new locomotive road was driven northwards to a virgin area of coal, the output of Pidwellt and McLaren collieries would use this road. The 1,100 hp winding engine in the north pit was retained and double-decked, two mine cars per deck, and carriages installed that could handle 336 tonnes of coal per hour. The coal reserves of the McLaren and Rhymney Merthyr collieries were assigned to Ogilvie and those collieries linked to Ogilvie, with the Rhymney Merthyr shafts being abandoned in 1968. The NCB estimated that this would give the colliery a life of 60 years.

In 1955 out of the total colliery manpower of 997 men, 435 of them worked at the coalfaces, in 1956 the coalface figure was 476 men, and in 1961 out of the total colliery manpower of 1,425 men, 556 of them worked at the coalfaces. In 1957 this colliery was the centre of a major reconstruction scheme costing £5 million, with 300 contractors employed on the surface of the mine modernising facilities. A new pit bottom, fifty yards higher, was made in the North Pit and a new locomotive road was driven northwards to a virgin area of coal, the output of Pidwellt and McLaren collieries would use this road. The 1,100 hp winding engine in the north pit was retained and double-decked, two mine cars per deck, and carriages installed that could handle 336 tonnes of coal per hour. The coal reserves of the McLaren and Rhymney Merthyr collieries were assigned to Ogilvie and those collieries linked to Ogilvie, with the Rhymney Merthyr shafts being abandoned in 1968. The NCB estimated that this would give the colliery a life of 60 years.

In 1961 this colliery was still in the No.5 Area’s, No.1 Group along with Elliot and Groesfaen collieries, the Group’s manpower was 3,643 men, while the total coal production for that year was 814,099 tons. The Group Manager was J.H. Jenkins, and the Area Manager was G. Tomkins. From 1969 to the closure the manager was Gordon Robinson.

The 1962 annual review stated that within ten years the main reserves available to Ogilvie would be in the Lower Four Feet and Seven Feet seams., the highly productive Rhas Las and Upper Four Feet seams being exhausted. Consequently, planned output was reduced from 713,000 tons to 512,000 tons. This reduction in output is the main reason for reducing overall OMS from 29.3 cwts to 25.7 cwts. Profitability was increased to 17/1d per ton. In the 1963 annual review output remained the same, overall productivity has been increased to 27.2 cwts but profitability has been reduced to 14/6d per ton.

That forecast of a future life of 60 years was proved to be way off the mark, in 1971 a fire meant the loss of one district from which the colliery never recovered, and it closed in March 1975.

Prior to closure, the pit was working three coal faces, both the S54 and S60 coalfaces were fitted with double-ended Trepanner coal cutters and the L8, with a thinner coal section was cut by a plough dragged up and down the face by a chain pulled by two motors, one each end of the ‘face. The coalface roof supports were steel bars on top of hydraulic props.

It was almost midnight on Saturday the 6th of February 1971 when the deputy on his inspection tour of the South pit saw dense smoke coming out of the workings, at the same time the fan attendant on the surface noticed smoke coming out of the fan drift. Immediately emergency procedures were followed and at 3.30 a.m. the following morning, a probing team was sent down only to be driven back by the intense heat and thick smoke. Another team went down at 7.30 a.m. but again was driven back by the conditions. The decision was then made to stop the Ogilvie fan but keep the McLaren fan running, and fire hoses were directed down the Ogilvie shafts to help the airflow towards the fire area. Just after 5 p.m. on that Sunday, they were able to roughly locate the suspected fire by noticing that the telephone cable to the South District loading point 650 yards from the pit bottom was damaged. At 11.30 p.m. a team was sent in as far as the junction to the South District. They broke the water columns to allow the water to seal off the district. Various other probing teams were beaten back by the heat which reached 80 degrees Fahrenheit so it was agreed to seal off the air floor by erecting temporary air doors.

AT 9 a.m. on Wednesday a team confirmed that a fire was still burning in the South District, but by now other teams were ready to fight the fire and it was subdued by 7 p.m.. The cause of the fire was never found but it was suspected that a faulty electrical transformer may have started it.

The NUM lodge at the colliery disputed the closure claiming that there were 12 years of work in the Seven-Feet seam and 15 years of work in the Three-quarter seam. They asked for a one year trial period but this was refused.

At the time of closure, the colliery was producing 25 hundredweights of coal per manshift, with a coalface advance of 30 feet per week, one of the best performances in south Wales, but the saleable yield of the coal was only 43%.

The following seams had been extensively worked at Ogilvie; Upper-Four-Feet, Lower-Four-Feet, Yard, Red Vein, Rhas Las, and Seven-Feet. There were also workings in the Elled and Three-Quarter seams.

Some Statistics:

- 1923: Manpower: 877.

- 1924: Manpower: 1,163.

- 1925: Manpower: 1,100.

- 1927: Manpower: 1,383.

- 1928: Manpower: 1,494.

- 1930: Manpower: 1,503.

- 1931: Manpower: 1,530.

- 1932: Manpower: 1,368.

- 1933: Manpower: 1,023.

- 1934: Manpower: 1,050.

- 1935: Manpower: 1,080. Output: 370,000 tons.

- 1937: Manpower: 1,179.

- 1938: Manpower: 1,236.

- 1942: Manpower: 1,169.

- 1943: Manpower: 967.

- 1944: Manpower: 1,076.

- 1947: Manpower: 862.

- 1948: Manpower: 926. Output: 369,500 tons.

- 1949: Manpower: 926. Output: 369,500 tons.

- 1950: Manpower: 901.

- 1953: Manpower: 916. Output: 335,000 tons.

- 1954: Manpower:1,111. Output: 247,000 tons.

- 1955: Manpower: 997. Output: 266,092 tons.

- 1956: Manpower: 1,052. Output: 303,787 tons.

- 1957: Manpower: 1,063. Output: 275,510 tons.

- 1958: Manpower: 1,751. Output: 279,897 tons.

- 1960: Manpower: 1,425. Output: 352,149 tons.

- 1961: Manpower: 1,493. Output: 366,641 tons.

- 1962: Manpower: 1,484.

- 1965: Manpower: 1,447.

- 1967: Manpower: 1,304. Output: 420,388 tons.

- 1968: Manpower: 1,292. Output: 385,663 tons.

- 1969: Manpower: 1,027. Output: 278,010 tons.

- 1970: Manpower: 909. Output: 211,613 tons.

- 1971: Manpower: 629. Output: 142,126 tons.

- 1972: Manpower: 632. Output: 159,526 tons.

- 1973: Manpower: 510. Output: 81,158 tons.

- 1974: Manpower: 490. Output: 81,401 tons.

Information supplied by Ray Lawrence and used here with his permission.

Return to previous page