Crynant, Dulais Valley (791056)

In June 1963 The Times reporter wrote the following article:

The shadow of death is lifted from the Dulais Valley, Mr. I.L. Evans, chairman of the Neath Rural District Council said here today. There seems to be no better way of putting it. Four of the five pits put on trial in the valley 18 months ago have been kept open and productivity has increased by half. And today the first turves for a new colliery, Treforgan, were cut. It is hoped that the new pit, which will cost about £850,000, will provide jobs as older collieries near here are worked out. It is estimated that coal reserves at Treforgan are sufficient for 20 years. Full production will start in 1966.

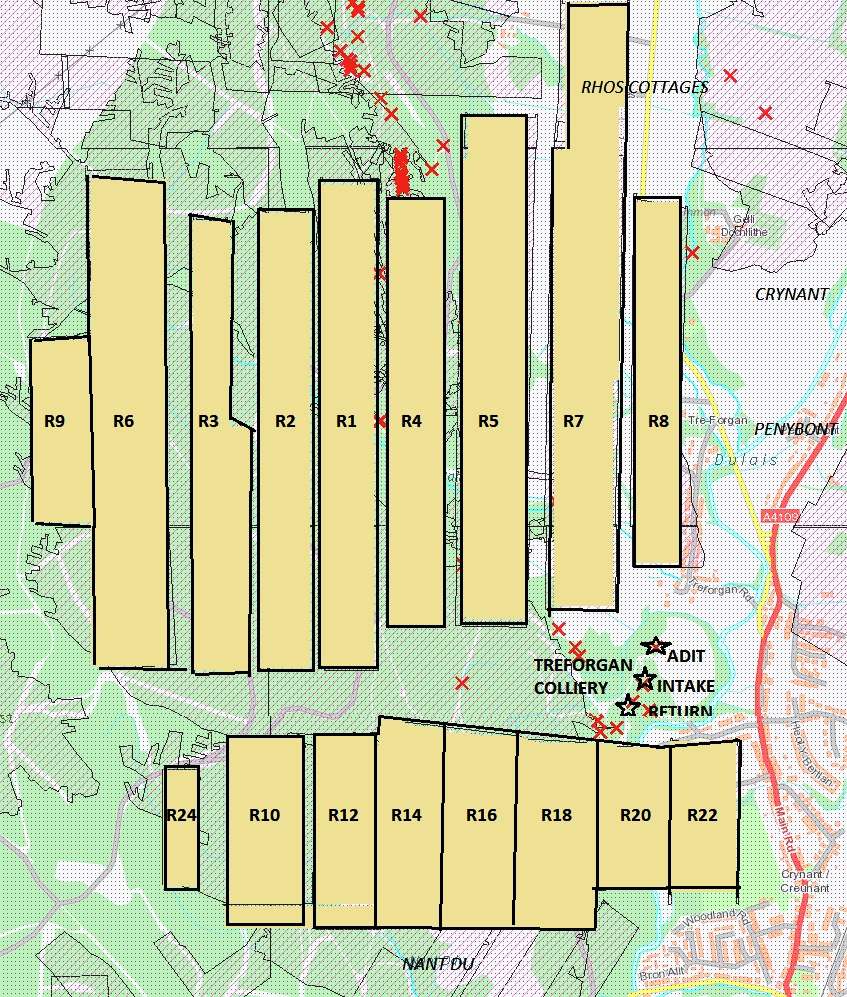

This was a National Coal Board anthracite drift mine that was developed between 1963 and 1966 at a cost of £1.5 million on the site of the old Llwyn-on Colliery. A link was also made to Cefn Coed Colliery in 1967 for ventilation purposes. Along with Lady Windsor Colliery, the NCB issued pocket radios for underground communications at Treforgan, the only mines in the South Wales Coalfield to use them. Two new slants were driven down at an incline of 1 in 3 to the Red Vein seam. It was originally intended that this mine would have a short life in limited Red Vein reserves but exceptional productivity figures made it one of the most profitable mines in the UK, and the most profitable anthracite mine. In January 1968 it was achieving a very creditable 3 tons output per manshift and was stated to be the most highly automated mine in the South Wales Coalfield. In 1969 this mine employed 285 men working underground and 31 men at the surface of the mine. All its coal output was taken to Abernant Washery by road.

This was a National Coal Board anthracite drift mine that was developed between 1963 and 1966 at a cost of £1.5 million on the site of the old Llwyn-on Colliery. A link was also made to Cefn Coed Colliery in 1967 for ventilation purposes. Along with Lady Windsor Colliery, the NCB issued pocket radios for underground communications at Treforgan, the only mines in the South Wales Coalfield to use them. Two new slants were driven down at an incline of 1 in 3 to the Red Vein seam. It was originally intended that this mine would have a short life in limited Red Vein reserves but exceptional productivity figures made it one of the most profitable mines in the UK, and the most profitable anthracite mine. In January 1968 it was achieving a very creditable 3 tons output per manshift and was stated to be the most highly automated mine in the South Wales Coalfield. In 1969 this mine employed 285 men working underground and 31 men at the surface of the mine. All its coal output was taken to Abernant Washery by road.

In July 1971, forty-three miners were injured when the manriding train that they were in ran loose. Nineteen of them were taken to hospital after they jumped from the moving train.

In July 1971, forty-three miners were injured when the manriding train that they were in ran loose. Nineteen of them were taken to hospital after they jumped from the moving train.

In 1973 the NCB proposed an investment of £7 million in developing the Nine-Feet and Bute seams in preparation for the exhaustion of the Red Vein in c1980. A new drift was driven from the surface, and another roadway was driven 1,370 metres into the new take to exploit an estimated 20 million tonnes of reserves. Further roads reaching another 600+ metres, new bunkers, 2,440 yards of conveyors, improved manriding and transportation of materials and a new surface re-organisation were all envisaged. On the surface, new workshops, stores and a haulage house were constructed. In 1969 the manager was E. Powell, in 1970/71 it was N. Lewis, in 1972 it was B. Langdon, in 1975 it was A.R. Jones and in 1976/80+ it was T. Clarke.

By 1981 the Red Vein had been worked out and Treforgan was working the Upper-Nine-Feet seam at a section of 147cm, and the Bute seam at a section of 98cm. Self-advancing supports were used in both the seams, with coal cutting in the Upper-Nine-Feet seam by ranging drum shearer, and in the Bute seam by Gleithobel plough. The Upper-Nine-Feet coalfaces; the N1 & N2 were 142 and 165 metres in length respectively with expected daily advance being 1.82 metres on two coaling shifts. The N1 had a life of 300 metres left in January 1981 with the N2 expected to open in January 1982. The Bute coalfaces; B1 & B2 also had lengths of 142 and 165 metres with daily advance expected to be 2.43 metres on two coaling shifts.

The expected output per man shift on the coalface was 3.03 tonnes, and overall for the drift 1.3 tonnes. The saleable yield of coal was 54% of the total colliery production. Manpower distribution was:

- Working at the coalfaces, 155 men

- Working at developing new coalfaces, 55 men

- Working elsewhere below ground 115 men

- Working at the surface of the mine, 60 men.

The manager at that time, Mr. T. Clarke, reported that it was in a very poor state, there was bad geology and steep gradients on the coalfaces – he had no men for development work – and the National Coal Board had withdrawn the contract workers. Due to adverse geological conditions, the colliery was without a coalface at the beginning of 1983 and dependent on the two 2,150 metre long extension intake and return roads being driven for its future. Following the 1984/85 Miners Strike the now British Coal abandoned plans to link Treforgan Colliery by underground roadway to Aberpergwm Colliery and closed the east side of the mine. Total closure followed not long after in 1985.

Some Statistics:

- 1969: Manpower: 316.

- 1970: Manpower: 453.

- 1971: Manpower: 473.

- 1972: Manpower: 470.

- 1974: Manpower: 475. Output: 227,000 tons.

- 1976: Manpower: 287. Output: 202,000 tons.

- 1979: Manpower: 482. Output: 158,000 tons.

- 1985:Manpower: 470.

If management and the NUM failed to come to an agreement over payments under the Area Incentive Scheme, assessors, comprising two from the NCB and two from the NUM, would visit the colliery and decide on the matter, here as an example is a typical assessors report:

It had been agreed that the following workplaces be subject to examination by the Assessors:

-

- B2 Face Drivage

- Main Intake North

- Main Return North

- Intake Heading East

- South Heading

We visited the colliery on Thursday, 13th August 1981, and our joint report is as follows. (1) B2 Face Drivage We were informed by the Colliery Manager, Mr. T. Clarke, that the drivage would cease on Friday, 14th of August, 1981. In consequence, no useful purpose would be gained by visiting this drivage and we eliminated it from the proposed programme.

Main Intake North:

-

- Supports – 14 ft. arches set at 2 ft. centres lagged with corrugated sheets.

- Gradient – Rising 1: 5

- Manning – 3 men/shift – double shift working Section –

- Coal approximately 36 inches Standard advance – 13 yards

- Machine – Eimco

This roadway is being driven to follow the seam. A fixed-length stage loader (approximately 30 yards in length) delivers material onto a 30-inch belt conveyor. In our opinion, from a gradient ranging from level to rising at 1: 6, the standard advance of 13 yards on double shift working is reasonable. However, for a gradient of 1: 6 to 1: 3.5, the standard advance should be reduced to 11.5 yards for double-shift working. All other specifications included in the addendum to the initial agreement for this heading to remain unchanged except for item 7 where in the distance for carrying or transporting material to the face of the heading be reduced to 35 yards.

Main Return North:

-

- Supports – 14 ft. arches set at 2 ft. centres lagged with corrugated sheets.

- Gradient – Rising 1: 10

- Manning – 3 men/shift – double shift working Section – All coal with coal roof

- Machine – Eimco

- Standard advance – 13 yards.

- Intake Heading East:

- Supports – 16 ft. arches set at 2 ft. centres lagged with corrugated sheets.

- Gradient – Almost level Section – Relatively strong stone

- Machine – Eimco Standard advance – 12 yards

- The debris is loaded out on an extended 30 inch chain conveyor, the extension of which is carried out by other NCB labour. We understand that this roadway will only be required up to the first cross-cut (approximately 90 yards) at which point it will be reduced to a 14 ft. arch roadway.

For the distance up to the cross-cut and taking into account the problems associated with filling out and the handling of supplies from the entrance of the heading (in this instance a maximum of 90 yards) it is our opinion that the standard advance be reduced to 10 yards.

South Heading: This heading was in the process of being formed, the first arch is set in the actual heading at the time of the visit. We feel that an assessment cannot be made until such time that all the facilities have been established.

General: During our visit it was apparent that there existed a lack of team spirit and co-operation among the development workmen. To overcome this attitude, which to our mind is essential if there is to be an improvement in the performance of the colliery, we suggest the following:

Management to ensure that all facilities installed for maximum performance are maintained up to date at ALL TIMES. That the development workmen be more involved with the Lodge in discussion on norm negotiations.

It was ascertained from the Conciliation Officer that at the meeting held at the colliery on July, 20th, 1981, the sentence ‘As per pit Agreement only delays over 20 minutes duration considered and only 50 per cent outbye delay time is payable’ would be deleted from Item 16 of the addendum to the above Agreements.

We the undersigned, confirm that this is a joint agreed report.

Signed: M. BANWELL (NUM) V. PRICE (NUM) B. JENKINS (NCB). B. WILLIAMS (NCB)

Information supplied by Ray Lawrence and used here with his permission.

Return to previous page