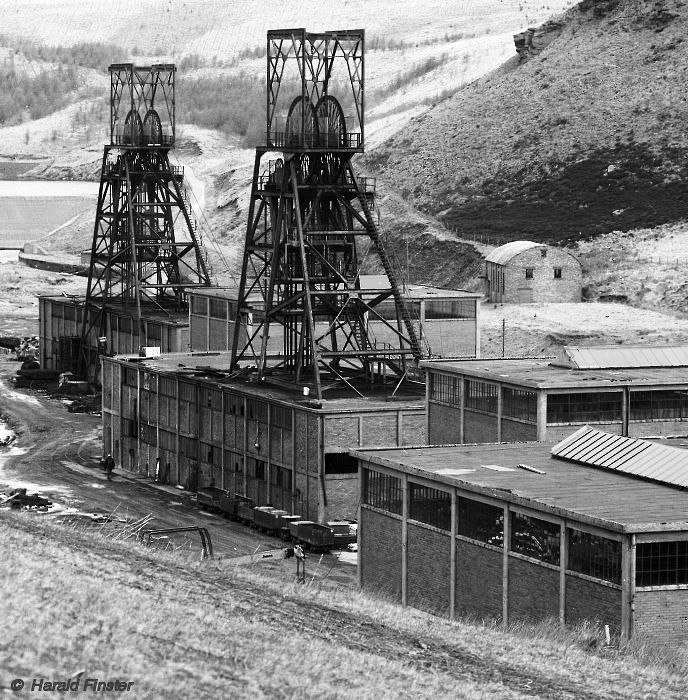

Maerdy, Rhondda Fach Valley (3 & 4 @ 96379987, 1 & 2 @ 974990)

Mardy Colliery 1990

Copyright © Harald Finster and used with his kind permission

In the bleak uplands of the Rhondda Fach Valley very little stirred before the sinking of the original Mardy Pits. So it did come as a surprise that this pit was named after a farm that seemed to be some sort of mayor or stewards house and was used for collecting rents and local meetings, etc..

Anyway, whatever it used to be was changed forever when in 1873 Mordecai Jones and his financial backer Wheatley Cobb purchased the mineral rights for 999 acres under the Maerdyfarm from the Miskin Estate for £122,000. It was estimated that this area had a vertical section of 75 feet of coal in total, of which 53 feet was in seams of two feet or over.

Mordecai Jones was born in 1813 and was the son of a Brecon boat builder. He attended school in Brecon and on leaving entered the coal merchants business. Not satisfied with this he went on to own the Breconshire Brewery, the Abergavenny Gas Works and chairman of the Brecon Gas Works. He then turned his attention to the valleys just a bit further south than Brecon and to the rapidly expanding coal mining industry. In 1861 he sunk the Nantmelyn Colliery in the Cynon Valley and following the success of that eyed up the virgin territory around Maerdy. Jones was also Mayor of Brecon around 1854, deputy lieutenant for Breconshire and later the High Sheriff of Breconshire. He died in 1880.

The Mardy No.1 pit was sunk in 1875, and the No.2 pit in 1876 both to the Abergorchi seam. The first commercial coal was raised in 1877 and transported to Cardiff Docks by the newly laid Maerdy Branch of the Taff Vale Railway.

In 1878 the pits were leased out to Locket’s Merthyr Company, who, on the 8th of January 1878 placed this advertisement in the newspapers:

MESSRS. LOCKET’S MERTHYR’S STEAM COAL COMPANY (LIMITED) are prepared to receive TENDERS for the following WORK to be done at their Maerdy Colliery, and MATERIALS therefore:

-

- SINKING the TWO existing PITS to the steam coal seams.

- Per 130,000 3 inch FIRE BRICK for the boiler stack.

- BUILDING A BOILER STACK.

- For 200,000 one inch BRICK LUMPS for pit walling.

- Per 50 yards New or Second-hand 5-inch WATER PIPES.

Both pits were 16 feet in diameter and eventually sunk to a depth of 1,155 feet. In 1881 electric pumps were installed underground at this colliery, possibly the first in South Wales. The pump also operated a dynamo which provided lighting for the pit bottom, engine houses, stables and the main roadway for 600 feet. Locket’s investment in the colliery started to payoff and from an output of 30,000 tons of coal in 1879 they were hitting 160,000 tons by 1884.

There was little sign of industrial unrest during this period, with a newspaper article on the 25th of April 1884 stating;

The inhabitants of the village or town of Mardy have long felt the need for a suitable place where they could assemble for social recreation and other purposes. This want has now been supplied, thanks to the enterprise of Mr. John Davies, of the Mardy Hotel, who at considerable cost, has erected suitable and commodious premises for gatherings of that nature. The hall, which was designed and built under the supervision of Mr. D.J. Davies, architect and surveyor, is excellently fitted up with admirable appointments and is well adapted for the purposes it is intended to serve. The formal opening took place on Wednesday morning in the presence of a large number of spectators. In the afternoon and evening, great performances of the ‘Wreck of the Argosy’ were given by the Mardy Harmonic Society, accompanied by the Merthyr String Band. A half-holiday was given to the workmen of Mardy Colliery on Thursday to give them the opportunity to witness the performance.

On the 7th of October 1892, the Colliery Guardian carried the following advert inviting tenders “for sinking and walling a 16 feet diameter pit”

The 16 feet in diameter No.3 pit was sunk in 1893 a mile further up the valley it was sunk to 15 yards below the Gellideg seam at a depth of 500 yards. Coal winding was originally from the Bute seam landing a at a depth of 428 yards. The steam winding engine had two horizontal cylinders 42 inches in diameter with a six-feet stroke. The drum was 19 feet in diameter with the headgear for this pit being 73 feet high. Ventilation of the colliery was by Waddle fan of 45 feet diameter which produced 230,000 cubic feet of air per minute. At the No.3 Pit a Schiele fan was installed. Initially, four underground steam engines were used for hauling the trams in and out of the districts with the steam piped down the shafts. They were built by the Uskside Engineering Company. Lockets Merthyr Steam Coal Company was incorporated in 1894, and in 1896 the No.1 Pit employed 360 men underground and 51 men on the surface, the No.2 Pit employed 744 men underground and 107 men on the surface and the No.3 Pit employed 187 men underground and 38 men on the surface. All were managed by James Miles. In 1897 the Nos.1 & 2 pits had a sidings capacity of 259 full wagons, 482 empty wagons, and 116 other wagons. While the No.3 pit had a sidings capacity of 54 full wagons, 158 empty wagons and 95 other wagons. In 1901 there were still four steam driven haulage engines working underground. In 1908 the No.1 employed 731 men, the No.2, 916 men with 225 men on the surface while the No.3 employed 495 men underground and 61 men on the surface, the manager for all pits was H.E. Maltby. In 1918 the total manpower was 1,754 men underground and 320 men on the surface with the manager being R. Lewis.

In 1915 the Business Statistics Company in its book on the South Wales Coal and Iron Companies stated that the “Company originally owned 3 Pits, which are situated at Mardy, near Ferndale. On January, 1st, 1910 the Company took over the Atlantic Merthyr Collieries Limited, which worked the Cilely Colliery, near Llantrisant”.

The board of directors consisted of; W. Ronnfeldt, Chairman, W.H. Mewton, W. Gascoyne Dalziel, H.A. Griffin, Humphry Wallis and John Cory. This company was a member of the Monmouthshire and South Wales Coal Owners Association. The 16 foot diameter No.4 pit was sunk alongside the No.3 pit in 1914, and was originally used as an upcast shaft, and for winding from the Gorllwyn seam. At first, sunk to the Six-Feet seam it was later deepened to the Bute seam. In 1919 the manager of the Nos. 1 & 2 Pits was B. Lewis and of the Nos. 3 & 4 it was D. Roberts. At that time the No.1 Pit employed 850 men, the No.2 Pit employed 1,000 men, the No.3 Pit employed 750 men and the No.4 Pit 100 men.

In 1923 the company was based at Baltic House, Mount Stuart Square, Cardiff and was producing 700,000 tons of steam coal annually. The directors were; W.H.D. Mewton (chairman), John Cory, W.G. Dalziel, H.A. Griffin, D. Hannah, H. Wallis. At that time Cilely employed 300 men, the Nos. 1 & 2 Pits employed 1800 men, with none employed at the Nos. 3 & 4.

At that time Mardy was in the Rhondda No.1 Section of the SWMF along with; Hendrewen, Bute Merthyr, Cilely. Mardy, Fernhill, Naval. Tylorstown, Coedely. Gelli, Park and Dare, National. Tynybedw, Maindy and Eastern, Abergorky, Ferndale, Albion, Llwynypia, Ynysfaio, Standard, Cymmer, Blaenclydach, Lewis Merthyr, Cambrian, Tydraw, Lady Lewis

The pits remained idle during 1927 due to the trading and industrial relations situation, the managers at that time were Nos. 1 and 2, J. Davies and Nos. 3 and 4 it was J. Thomas. Work resumed on the 14th of September 1928 when around 100 men were taken on the books. In 1930 the local miner’s lodge was expelled from the SWMF and remained so until merged with the new lodge in 1934. The Nos.1 and 2 pits were closed in 1932 when the Bwllfa and Cwmaman Collieries Limited took control of the colliery. This company was based at Aberdare House, Mount Stuart Square, Cardiff and was under the chairmanship of Sir David Rees Llewellyn. The other directors were; Sir J. Field Beale, T.J. Callaghan, W.M. Llewellyn, H.H. Merrett and J.H. Jolly. At that time this company controlled six collieries and produced about 2,400,000 tons of coal. It was part of Welsh Associated Collieries Limited by then and at this colliery, the Yard, Nine-Feet and Seven-Feet seams were worked.

D.R. Llewellyn was born in 1879 at Aberdare, the son of the general manager of the Bwllfa and Merthyr Dare Collieries. He was educated at Aberdare and Llandovery College before following a course in mining engineering at University College, Cardiff ( 1901-03 ). He went to USA for 2 years to gain more experience and on his return he began to acquire local pits and then more widely in south Wales, pioneering the use of new coal-cutting machines which he had seen in America. In 1916, as chairman of the Gwauncaegurwen Coal Company, and the Cambrian Combine. He became a director of many enterprises in the coal trade, especially the Vale of Neath, Amalgamated Anthracite Collieries, Guest, Keen & Nettlefold, and chairman of the Welsh Associated Collieries and later vice-chairman of the United Powell Duffryn Associated Collieries (under the chairmanship of Edmund Hann ). By about 1920 it could be claimed that he owned or managed about 1/7 of the South Wales Coalfield. He played an important part in the development of management methods in the coal industry and the growth of amalgamated companies. He died on the 15th of December 1940.

In January 1930, the coal mining interests of Guest, Keen and Nettlefolds Limited and Llewellyn’s many companies were merged into Welsh Associated Collieries Limited. This new company controlled around 25% of the South Wales steam coal trade, running sixty mines, and producing nine million tons of coal a year. It was estimated that they had 800 million tons of coal reserves. In exchange for setting up the new company, GKN held stock of up to £2,000,000 in value in it, with a total valuation being £8,890,000. D. R. was chairman of the new company and his brother, W.M. managed the mines.

Welsh Associated Collieries Limited consisted of;

Gueret Llewellyn and Merrett Ltd., D. Davies and Sons Ltd., Bwllfa and Cwmaman Collieries Ltd., Llewellyn (Nixon) Ltd., Llewellyn (Plymouth) Ltd., Llewellyn (Cyfarthfa) Ltd., Troedyrhiw Coal Co. Ltd., D.R. Llewellyn and Sons Ltd., The Aberdare Graig Coal Co. Ltd., The Duffryn Rhondda (1929) Ltd., The Cynon Coal Co. Ltd., and Guest Keen and Nettlefolds Ltd.

It merged with Powell Duffryn to form the Powell Duffryn Associated Collieries Limited in 1935.

Bad times had certainly hit the Coalfield, in 1921, 271,161 miners had produced 46,249,000 tons of coal, 20.1% of the U.K.’s total, by 1939 there were only 128,774 men at work producing 35,269,000 tons of coal, 15.2% of the U.K.’s. total. In 1931 unemployed within the Coalfield stood at 36% rising to an incredible 47% in 1932, in the period 1933, 1934, and 1935 the figures remained devastatingly high at 42%, 44% and 34% respectively, indeed they could have been much higher except for the relative prosperity of the anthracite section of the Coalfield, and for workmen leaving the area to seek work elsewhere – almost 22,000 men in the period 1931 to 1935. The Rhondda/Port Talbot registration area was particularly badly hit during this period with unemployment peaking at 60% in 1932.

In 1930 dole payments came to 12 shillings (60p) for a man and 4 shillings (20p) for each child per week, but even this paltry figure was too much for the local boards to bear and in 1935 these payments were cut creating a situation of near starvation. The whole of the area was categorised as a distressed area and was only saved economically by the threat of, and outbreak of the Second World War. The miners wage per shift in 1934 had dropped to 9 shillings (45p). It was only the advent of re-armament for the Second World War that brought relief to the area.

Work was again suspended in 1934 and during this time the No.4 Pit was deepened to the Bute seam and a new 1,200 feet long drift driven to work the Nine-Feet and Six-Feet seams. In 1935 Welsh Associated Collieries merged with Powell Duffryn to form Powell Duffryn Associated Collieries Limited. In 1935 Mardy Colliery was managed by J.S. Evans and employed 120 men on the surface and 880 men underground, that is when the colliery was in operation. This colliery had its own coal preparation plant (washery). A new underground drift was driven opening up new areas of the Nine-Feet and Six-Feet seams but Powell Duffryn again closed the colliery for a while, and then re-opened it in 1936 on their own terms, with by 1938 only 330 men being employed there. No check weigher was allowed, and no fixed price list for wages agreed to, the South Wales Miners Federation Lodge was at the least ignored, and at the most deliberately impeded.

Powell Duffryn finally closed the pit in 1940 when the main market for Mardy’s coal, France, fell to the Germans. On closure, there were eighty horses working in the No.3 Pit.

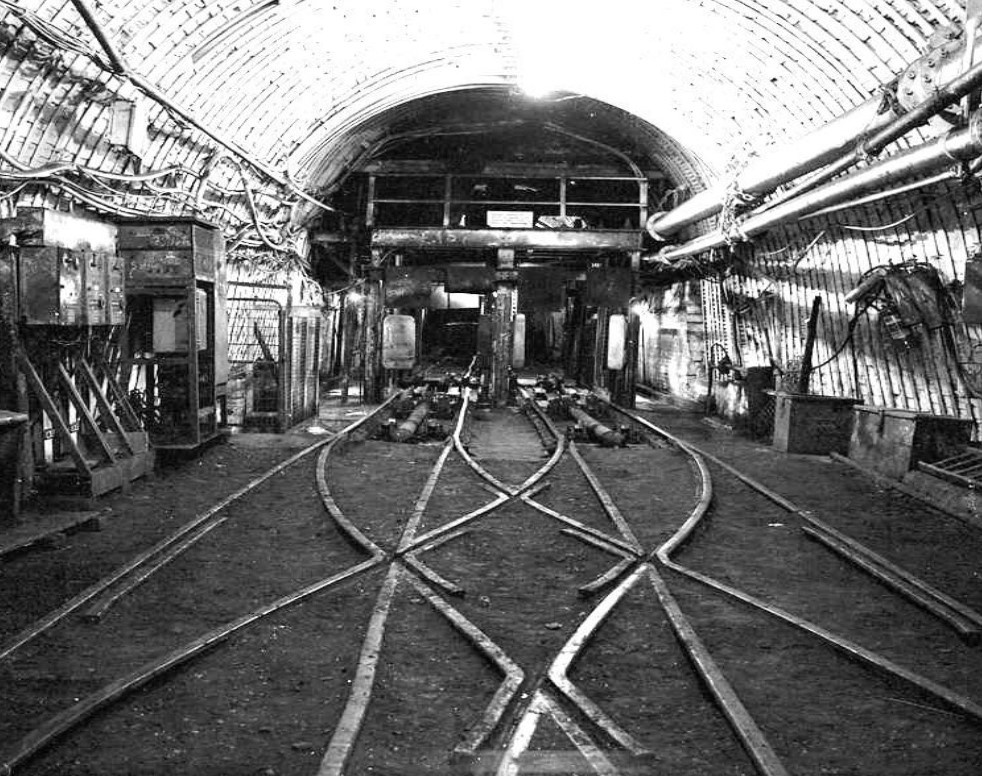

On Nationalisation in 1947 Mardy Colliery was placed in the National Coal Board’s, South Western Division’s, No.4 (Aberdare) Area, and at that time employed 5 men underground and 10 men on the surface on a maintenance basis. The manager was B. Lloyd. In 1949 the NCB announced that the first complete colliery re-development in the South Wales Coalfield was to be carried out on the site of the Nos.3 & 4 pits. It was estimated that there were twelve workable seams from the Gorllwyn down to the Gellideg that would yield 120,000,000 tons of coal and give a colliery life of 125 years and cover an area 5 miles by 3 miles. In a five million pound scheme, the surface facilities were completely modernised and the colliery was linked by a 3,200 yard long underground roadway to the Bwllfa Dare pit in the Cynon Valley. It was ultimately expected to link up with Tower No.4 Colliery, with both Tower and Bwllfa No.1 Pit being the upcast ventilation shafts and the Mardy 3 and 4 Pits being the downcast ventilation shafts. 65 hp Electric locomotives were used underground to haul coal trains of 35 trams, each tram was capable of holding three tons of coal at a speed of nine miles per hour. The No.3 Pit had an electrical winding engine of 950 hp, and was capable of raising 18 men per wind while the No.4 pit had a 1,600 hp engine and was capable of winding 36 men or three tonnes of coal per wind. It was estimated that the No.3 Pit would wind 2,500 tons of coal per day, and the No.4 Pit would wind 3,500 tons of coal per day. Three cross-measure drifts were driven from 242 yards/325 yards and 408 yards deep in the shafts to an estimated 80,000,000 tons of coal that lay to the northwest of the shafts. It was proposed to drive another cross-measure drift at a depth of 485 yards in 50 years to expose another 33,000,000 tons of coal. In 1954 the new mine was in full operation and employed 185 men on the surface and 890 men underground working the Two-Feet-Nine, Four-Feet and Six-Feet seams, while the Bwllfa section worked the Five-Feet seam. The manager was D.M. James.

The Coal News had this to say about it:

There is the sound once more of miners’ boots on the Burma Road. Built and nicknamed during the war, the Burma Road links Mardy Village with the upper reaches of the Rhondda Fach the little Rhondda valley, where Mardy III and IV headframes rise under the ice of the western slopes.

For ten years that road has been deserted except for the maintenance men at the disused shafts –men whose numbers dwindled through the years from thirty to six. Those, and Tom Sydenham, Ivor Reedwell and Bill Stapleton, pit-shaft masons who came to inspect the brick-faced shafts at routine intervals.

The pits closed down on the fall of France in 1940 when their market for dry steam coal collapsed. That closure, hard on the heels of earlier troubles, meant more than a mere cessation of work. A blight fell upon the village of Mardy. Those of the younger men who stayed miners reached out to Ferndale and further afield. Many crossed the mountains to work in the pits of the neighbouring Aberdare valley.

The older men stayed in Mardy and ate their hearts out. Government trading estates were built to absorb surplus labour. Slowly there grew to manhood a generation of Mardy youngsters who had never been inside a pit. Now, all is changed. In Aberaman, across the Graig Mountain, men have been busy at their drawing boards, under E.J. Simons, A.M.I.M.E. No.4 Area Chief Planning Engineer, a staff of six have worked out a £4,000,000 scheme which aims at getting the 120 million tons of coal reserves known to lie beneath the mountains at the head of the valley.

The Mardy project is inextricably linked with the fate of two other collieries, Bwllfa and Ferndale. Full production has been achieved, six or more years from now, a working loss of nearly £250,000 will have been wiped out and replaced by a profit.

A MILLION TONS MORE

Nor is this all. The nation will benefit yearly to the extent of a million tons of some of the best sub-bituminous coal in South Wales. Economic working, good conditions and a profit, this is in truth national planning.

Bwllfa II and Ferndale pits will be closed just as the Mardy project has been completed and proven. At present, they are uneconomic and likely to get worse. There are faults to the west of Bwllfa, and several stonedrifts would be necessary to reach the major reserves beyond, there is a syncline to the south of the present workings.

As for Ferndale, coal production is now confined to small remote pillars bounded by waste areas. Little coal remains apart from reserves of coal for the No.IX, which they plan to work from an adjacent valley.

It is clear, then, that labour in these villages will be kept in productive employment if the Board goes ahead with the Mardy project.

On the 20th of December 1955 at 10.30 am in the T2 Conveyor of the Two Feet Nine seam shot firing caused an ignition of gas –luckily no one was hurt. In April of 1956, 22 men staged a 16-hour long stay down strike claiming that the air velocity was to high. In 1955 out of the total colliery manpower of 664 men, 286 of them worked at the coalfaces.

With the start of the new mine, the coalface figure jumped to 399 men in 1956 and further up to 483 men working at the coalfaces in 1957. In 1958 the coalface figure had dropped back down to 344 men. The surface of Bwllfa Colliery was closed in 1957 and the workforce transferred to Mardy. Development of the mine was still continuing as late as 1958 when the mining contractors, Cementation employed 64 men at Mardy to work on staple shafts and drivages. In 1961 this colliery was still in the No.4 Area and consisted of a whole Group on its own. It employed 1,502 men and produced 312,000 tons of coal. The Group Manager was T.G. Jones and the Area Manager was T. Wright. Every year the NCB would hold a review of all its collieries. In 1962 it commented that very difficult geological conditions could affect the future of this pit, in view of this they dropped the planned annual output of coal to 460,000 tons. The planned output per manshift (OMS) was to be 27.2 cwts and profits would be 11/10d (60p) per ton. Poor results continued for the first half of 1963 but then the pit picked itself up, shook itself down, and made a profit of 40p per ton with an OMS 26.9cwts, overall for the year, not up to the plan but going the right way.

In January 1970 this colliery was closed for a few weeks and the men transferred to other collieries while the safety of the walls protecting the Lluest Wen water reservoir was investigated.

During the 1972 strike over wages, it was claimed that pickets at Mardy threatened the wives and children of the officials who continued to work at the colliery. The South Wales president of the National Association of Colliery Overmen, Deputies and Shotfirers claimed that they were shouting “Your wives and families can look out.”

An NCB leaflet printed in 1979 gave this colliery a reserve of coal of seven million tonnes. At that time the coalface output per manshift was down to 4 tonnes, and overall for the colliery, it was 0.9 tonnes. It was producing an average of 3,000 tonnes of coal per week. Around the same time the NCB published the Plan For Coal which projected the future of the Coalfield –there was no mention of Mardy. In 1981 the pit was working the Five-Feet seam at a section of between 122 and 147cm, the Seven-Feet seam at a section of between 122 and 133cm, the Gellideg seam at a section of 66cm, and the Yard seam at a section of 91cm, The Five-Feet and Seven-Feet seams were cut by ranging drum shearers, with roof supports on the coalface being the self-advancing types. The Gellideg and Yard seams were cut by Gleithobel plough and roof supports on the coalface were either self-advancing or post and bars. Coalface length varied from between 90 and 183 metres. Expected output per manshift at the coalface was 5.3 tonnes, and overall 1.41 tonnes.

The saleable yield of coal was 66% of total production. The coalfaces in the Five-Feet seam were prefixed by the letter V, with the V3 coalface advancing 2.5 metres per day on two coaling shifts and having a life of 1,400 metres. The V2 was advancing 1.9 metres per day on a single shift and had a life of 460 metres. In the Seven-Feet seam the coalfaces were prefixed with the letter B, the B2 coalface had an expected advance of 2 metres per day on double-shift coaling. It had a life of 1,350 metres and was anticipated to start in March 1982. The Gellideg seam coalfaces were prefixed with the letter D, the D1 was advancing by 1.6 metres per day on a single shift with a life of 340 metres. In the Yard seam they were prefixed by the letter Y, the Y7 had a life of 900 metres with an expected advance of 0.6 metres on single shift. Manpower deployment was; coalface 200, development 120, elsewhere below ground 230, and on the surface 228. The manager at that time M. J. Williams was concerned about his manpower levels, having 864 men on books when the agreed figure was 893 men. The NCB had put an embargo on recruitment. In 1983 Mardy Colliery was listed as losing £36.70 for every tonne of coal that it produced the fifth worst figures in the Coalfield.

During the 1984/85 miner’s strike, on the 25th of February 1985, Tim Jones, reporting for The Times, stated somewhat eloquently:

“…Mardy remains the bunker. It did not gain the sobriquet of Little Moscow lightly, nor its reputation of being first out and last back in any dispute. Ingrained in socialism and sustained by tales of glorious struggles of the past, the men of Mardy proclaim they would rather eat grass than return to work without the direction of the national leadership…the men believe that if the strike is lost their community will be finished.”

Mardy Colliery lost two coalfaces during the 1984/85 miner’s strike, and after a month back in work could only reach 37% of expected production figures.

In February 1989 the Coal News reported:

Rhondda Valley’s last miners harnessed high underground standards to rapid coal cutting techniques to find a winning formula of both safety and output.

Double-shifted teams on Mardy Colliery’s B2 face achieved a record 36 machine cuts in five days, six and a half cuts more than their previous best –and rounded off their success by scooping up the runners-up spot and a £300 prize in the South Wales Group’s underground standards contest.

Their end of year run in the Seven-Feet seam produced a record 5,201 tons of saleable domestic coal with a face oms of 11.61 tons.

B2’s -160 metres long with a planned cutting distance of 700 metres –is equipped with two conventional AB 16 shearers operating a bi-directional system in sound geological conditions.

The pit –now part of the Tower Colliery complex at Hirwaun –sends its coal along 11 kilometres of conveyors to join the trunk conveyor which feeds more than 13,000 saleable tons weekly to a new washery at Hirwaun.

However, record breaking, or any other means, could not prevent Mardy from falling foul of the ‘free’ market economic policy of the day and Mardy Colliery, the last deep mine to have worked in the Rhondda Valleys was then closed by British Coal in December 1990. Only 17 of the 300 men left at the pit opted for a transfer to another mine.

The last working shift was on December 21st 1990 and following the end of this shift carols were sung in the canteen and the Tylorstown Silver Band led a procession down to Maerdy Welfare Hall where a ‘wake’ was held.

Generally, this colliery’s coals were classed as type 201A Dry Steam Coal, which was usually non-caking and used for steam raising in boilers for ships, locomotives, power stations etc.

Six years later the site was cleared and Fenner plc constructed a factory there.

Some of the others who died at these pits;

- 28/09/1881 William Smith, Age: 32: Stoneman: Fall of the roof.

- 05/02/1883 Thomas Thomas Age: 15: Door boy: Fell under trams

- 5/10/1883, R. Jones, Age: 14: Door boy: Fall of coal.

- 12/11/1883, Isaac Morgan Age: 55: Collier: Fall of coal.

- 19/02/1886, Louisa Thomas, Age: 22: Oil girl: Killed by tram running wild down the incline.

- 4/01/1887, John Jones Age: 52: Collier: A small stone from the roof struck him on the head

- 15/03/1887, William Walters. Age: 47: Collier: Fall of roof

- 22/07/1887, John Treherne, Age: 35: Collier: Roof fall

- 1/10/1887, John Brooks, Age: 32: Labourer: Fal1 of roof in rubbish stall while stowing

- 03/10/1887, James Weaver, Age: 41: Labourer: Crushed by a tram against pack-wall.

- 14/12/1887, William Jones, Age: 50: Collier: Fall of slip of coal.

- 26/06/1888, James Davis, Age: 29: Haulier: Fall of roof

- 19/07/1889, Thomas Davies, Age: 39: Repairer: Fall of roof.

- 17/01/1890, Evan Evans, Age: 29: Haulier: crushed by trams.

- 9/08/1890, Thomas Thomas, Age: 21: Assistant repairer: Fall of roof

- 30/08/1890, Owen Thomas, Age: 34: Repairer: Fall of roof

- 4/10/1890, D. Handel Evans, Age: 15: Lamp boy: Crushed between the crank and a flywheel

- 23/01/1891 William Davies Age: 39: Rope examiner: The deceased had just gone out of the engine room and appeared to be crossing shaft siding when he was knocked down by the first of three trams which the hitcher was bringing forward.

- 18/11/1891, Rees Jones Age: 34: Repairer: Struck on the head by a stone

- 23/01/1892, John A. Jones Age: 33: Hitcher: Cage descended on him as he was crossing the pit.

- 26/10/1892, Job Howells, Age: 21: Hitcher: Fall of roof rock at face extending 12ft back

- 25/08/1893, Richard Hughes, Age: 40: Tipper: Crushed between trams while tipping at screens.

- 15/01/1894 George Davies Age: 30: Wagonman: Died on 25th January 1894 from injuries received while crossing between two waggons at weighbridge.

- 13/11/1894, Thomas Williams, Age: 59, Assistant roadman, Mardy No.2: Fall of roof.

- 26/08/1895, Ephraim Thomas, Age: 25: Collier: Fall of roof

- 16/09/1895, James Jones Age: 30: Haulier: Fall of roof on a double parting in New seam

- 11/02/1896 Thomas Chewins, Age: 48: Collier: Cage in which he and 11 others struck a stage at amid landing in the shaft. Died 24th June. (Ten others more or less injured.).

- 14/05/1896, Richard Evans, Age: 40: Collier: Fall at face.

- 27/05/1896 Jonah Davies Age: 28: Haulier: Died on 24th September from injuries to the spine having slipped his foot and fallen under in empty tram.

- 27/06/1896 John Cross, Age: 32: Pitman Crushed by machinery

- 7/10/1896, James Morgans, Age: 40: Collier: In attempting to step on the cage at mid-landing before the cage was drawn to the side he fell through the opening 12 to 14 inches

- 16/12/1896, Joseph Stone, Age: 45: Platelayer: Ran over by waggon having been struck down by a sprag with which he was attempting to sprag a wheel.

- 4/05/1897, Thomas Jones Age: 25: Assistant timberman: Fall of the roof on the main road

- 6/08/1897 David Davies, Age: 30: Assistant. repairer: Fall of roof

- 9/9/1897, John Rees Age: 30: Collier: Mardy No.1: While ascending in cage

- 18/11/1897, F.J. Smith, Age: 16: Collier: Crushed by the upsetting of loaded trams

- 25/02/1898, James Levell, Age: 58: Pumpsman: Ruptured and died twelve days afterwards. He was helping a haulier to push some full trams when he injured himself but did not call in a doctor

- 26/02/1898, John Hughes, Age: 29: Haulier: Crushed by cage descending upon while attempting to cross the shaft bottom instead of passing through the proper travelling road.

- 17/2/1899, Charles Rees Age: 20: Collier Colliery: Mardy No.3: Fall of roof at face

- 15/04/1899, J.B. Morgan, Age: 29: Haulier: Kicked by a horse which he was following up a drift on his way out after finishing his shift. Died from fracture of skull on 22nd May.

- 6/01/1899 W. Ford, Age: 40: Hitcher: He was either crossing through the shaft or he leaned too far towards the cage as it descended and was struck on the head by it.

- 10/07/1899, S.S. Charles, Age: 34: Haulier: Fell off gun and was crushed by tram

- 23/06/1910, D.W. Jones Age: 44: Collier: Fall of the side at the working face.

- 9/03/1910, H.A. Whiting, Age: 29: Labourer: Run over by journey of trams.

- 18/10/1910, H.K. Jones Age: 46: Repairer: Fall of roof and side on a road during repairs.

- 25/02/1911, Moses Jones Age: 38: Collier: Fall of roof at working place

- 17/06/1911, Ivor James, Age: 23: Repairer: Fall of side

- 2/09/1911 Samuel Fine, Age: 35: Collier: While walking out a journey of full trams ran over him

- 2/02/1912, Josiah D Jones Age: 24: Collier: In raising a lump of coal, he crushed his finger between it and the tram. He died on March 6th, 1912, from blood poisoning.

- 26/04/1912, William Whippie, Age: 26: Waggonman: He fell in front of a coal wagon.

- 26/06/1912, William Rees, Age: 19: Collier boy. Colliery: Mardy No.2: Fall of side at the working face.

- 8/10/1912 Peter Goll, Age: 32: Collier: Fall of roof on the roadway.

- 26/10/1912 David Edwards, Age: 60: Crushed between a full tram and the side

- 1/03/1913 James Thomas Bray, Age: 25: Collier: Fall of side at working face.

- 12/07/1913, Griffith Griffiths, Age: 15: Collier boy: As he was proceeding to his work he was kicked and fatally injured by a horse. He died the following day.

- 2/08/1913, William R Jones, Age: 17: Collier boy: Fall of roof on haulage road. 12/08/1913, John Taylor, Age: 51: Labourer: Run over by trams.

- 20/04/1914, Edward Jones, Age: 49: Waggonman: He was found dead by the side of two wagons which he had been letting down the siding;

- 27/06/1914, Henry May. Age: 15: Crane driver: He was found on the boiler road siding, run over by an empty train of trucks. He had been to the office for his wages and was returning to his work

- 13/08/1914, Walter Smith, Age: 35: Collier: Fall of roof at working face..

- 24/11/1914, William Lowe, Age: 36: Night haulier: He was run over and killed by a tram

- 31/10/1925, Rees Jones, Age: 36: Haulier: Run over by trams.

- 19/12/1929, Levi Illtyd Edwards, Age: 19: Assistant. timberman: Fall of roof

Some Statistics:

- 1879: Output: 29,337 tons.

- 1882: Output: 98,000 tons.

- 1884: Output: 160,612 tons.

- 1889: Output: 316,406 tons.

- 1894: Output: 318,939 tons.

- 1899: Manpower: 1,625.

- 1900: Manpower: 1,812.

- 1901: Manpower: 1,897.

- 1902: Manpower: No.1: 665, No.2: 884, No.3: 388.

- 1903: Manpower: No.1: 704, No.2: 913, No.3: 423.

- 1905: Manpower: No.1: 632, No.2: 863, No.3: 466.

- 1907: Manpower: No.1: 649, No.2: 914, Surface: 184, No.3: 546.

- 1909: Manpower: No.1: 844, No.2: 1,028, No.3: 556.

- 1910: Manpower: No.1: 747, No.2: 874, No.3: 556, Surface: 299.

- 1911: Manpower: No.1: 792, No.2: 988, No.3: 516.

- 1912: Manpower: No.1: 775, No.2: 897, No.3: 618, Surface:310.

- 1915: Manpower: No.1: 850, No.2:1,000, No.3: 750.

- 1919: Manpower: 2,700.

- 1920: Manpower: No.1: 850, No.2: 1,000, No.3: 750, No.4: 100.

- 1922: Manpower: 3,200.

- 1923: Manpower: 3,200. Output: 700,000 tons.

- 1924: Manpower: 1,068.

- 1927: Manpower: 3,200.

- 1928: Manpower: 197.

- 1930: Manpower: 1,910.

- 1932: Manpower: 1,000.

- 1933: Manpower: 81.

- 1934: Manpower: 75.

- 1935: Manpower: 1.000. Output: 275,000 tons.

- 1936: Manpower: 330.

- 1937: Manpower: 371.

- 1938: Manpower: 447.

- 1940: Manpower: 413.

- 1941: Manpower: 53.

- 1942: Manpower: 36.

- 1944: Manpower: 29.

- 1947: Manpower: 15.

- 1948: Manpower: 15.

- 1950: Manpower: 180.

- 1953: Manpower: 393.

- 1954: Manpower: 975. Output: 83,272 tons.55

- 1955: Manpower: 664. Output: 126,390 tons.

- 1956: Manpower: 901. Output: 166,472 tons.

- 1957: Manpower: 1,048. Output: 209,288 tons.

- 1958: Manpower: 979. Output: 176,616 tons.

- 1959: Manpower: 1,256. Output: 226,921 tons.

- 1960: Manpower: 1,502. Output: 312,962 tons.

- 1961: Manpower: 1,622. Output: 393,962 tons.

- 1962: Manpower: 1,632. Output: 396,393 tons.

- 1963: Manpower: 1,576. Output: 448,840 tons.

- 1964: Manpower: 1,656. Output: 430,645 tons.

- 1965: Manpower: 1,564. Output: 368,886 tons.

- 1966: Manpower: 1,454. Output: 381,224 tons.

- 1967: Manpower: 1,398. Output: 373,164 tons.

- 1968: Manpower: 1,321. Output: 292,977 tons.

- 1969: Manpower: 1,225. Output: 233,924 tons.

- 1970: Manpower: 1,139. Output: 249,831 tons.

- 1971: Manpower: 1,086. Output: 221,313 tons.

- 1974: Manpower: 1,120. Output: 253,000 tons.

- 1976: Manpower: 1,073.

- 1979: Manpower: 865. Output: 200,000 tons.

- 1980: Manpower: 867. Output: 200,495 tons.

- 1981: Manpower: 778.

- 1984: Manpower: 773.

- 1990: Manpower: 777.

This information was supplied by Ray Lawrence and is used here with his permission.

Return to previous page