Blaengwynfi and Glyncorrwg, Afan Valley (88780010)

Blaengwynfi and Glyncorrwg, Afan Valley (88780010)

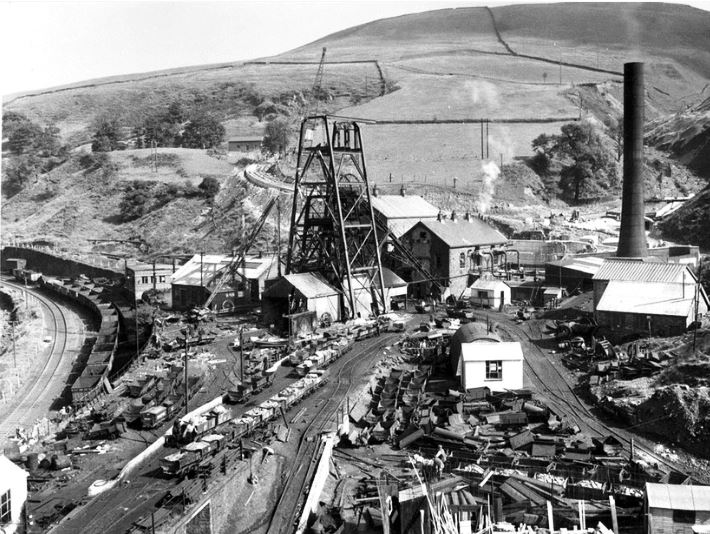

The Glyncorrwg levels (890000) were working as early as 1860/5 when owned by David Rees. The Glyncorrwg Pits were situated at Blaengwynfi and were 900 feet above sea level and six miles north of Maesteg, the Glynconwg Levels were at Glyncorrwg. In 1878/84 the manager of the Levels was Ed Plummer and in 1896 the manager was Howell John. The North and South Pits were completed in 1904, the North Pit (upcast ventilation shaft) was 16 feet in diameter and sunk to a depth of 417 yards to the Red Vein, and the South Pit (downcast ventilation shaft) was 18 feet in diameter and sunk to a depth of 403 yards to the Six-Feet seam of the Middle and Lower Coal Measures for steam, manufacturing, house, and anthracite coals.

On the 30th of September, 1891 eight of the shaft sinkers were killed when the bowk that they were in overwound. The men who died were; Thomas Thomas aged 28 years, James O’Connor aged 35 years, Humphrey Jenkins aged 28 years, Richard Skinner aged 28 years, William Evans aged 51 years, William Thomas aged 35 years, Dan Thomas aged 32 years and William Carpenter aged 45 years. The inquest was held before Mr. Cuthbertson, Coroner when the jury returned a verdict of ‘Accidental Death.’

The Inspector commented:

My opinion was and still is, that the engineman had his attention taken off his work for a moment by the entrance of his mate to relieve him, while raising the bowk with the men in it that he allowed the bowk to ascend too far before attempting to shut off the steam and apply the brake, and on discovering his mistake he lost his head and overwound the bowk.

I believe that the machinery was in perfect order.

It is of course, possible that, had a detaching hook had been in use, the lives might have been saved. But their use is not compulsory, and, moreover, their effectiveness in the prevention of accidents is in question.

For these reasons I have not suggested their adoption, thinking it better to leave it to the owners and managers to adopt them if they have confidence in them, or trust the machinery and the engineman if they have not such confidence.

The Nine-Feet seam was worked and actually did have a thickness of nine feet. The Six-Feet seam was worked and had a thickness of seven feet one inch, but had dirt partings. The No.2 Rhondda seam was extensively worked and had a thickness of coal, 10 inches, dirt 10 inches, coal 34 inches.

Based on the Nine-Feet seam its coals were classed as type 201A Dry Steam Coal, low volatile and usually non-caking, they had both low ash and low sulphur content and were used for steam raising in boilers for 72 ships, locomotives, power stations etc.

The Pits remained idle between August 1912 to 1919 when the South Pit was re-opened in the Red Vein and employed 144 men. In 1912 the Levels employed 609 men working the No.2 Rhondda seam, and the Pits employed 560 men. The manager of the levels at that time was Matthew Evans while the pits were managed by G. Rowlands.

The Levels were served by the South Wales Mineral Railway, and the Pits by the Rhondda and Swansea Bay Railway, both the Levels and the Pits came under the control of Glyn Neath Collieries Limited in 1926 who employed 384 men in 1927 working the Nine-Feet and Peacock seams.

In December 1927 the Colliery Guardian reported that the Glyncorrwg Colliery Company had gone into liquidation and in 1928 Amalgamated Anthracite Collieries Limited took control of the colliery.

Although it is not listed in 1934, it is shown to employ 995 men in 1938. In 1943/5 the manager was W. Moore and employed 518 men underground working the Nine-Feet and Peacock seams and 116 men on the surface.

On Nationalisation in 1947 the colliery was placed in the National Coal Board’s, South Western Division’s, No.2 Area, Afan Group, and employed 108 men on the surface and 587 men underground working the Nine-Feet, Six-Feet and Peacock seams. The manager was E.L. Powell.

The same seams were being worked in 1954 but manpower had increased to 134 on the surface and 638 men underground with the manager still Mr. Powell. The colliery was producing 800 tons a day in that year. In 1954/55 this colliery was one of 42 that caused concern to both the NCB and the NUM over the high level of accidents.

On the 13th of January 1954, there was an explosion that injured twenty miners, the district had to be sealed off permanently to prevent the fires from spreading. At around 9.30 am a collier hit a steel wedge with a sledgehammer creating a spark that caused an explosion of methane gas out of which a flame shot along the coalface. Out of the 32 colliers working on the coalface, 17 received severe burns, 7 were slightly burned and 8 were untouched. A rescue party put out all the clothing that was on fire but when they reached the No.7 stent they were forced back by the intense heat. Just before noon, the roof collapsed in this area releasing more gas and flames started to burn along the coalface. It was then decided to pull out of the district and seal it off to prevent fresh air from entering and prolonging the fires.

In March 1955 new pit head baths were opened, they had cost £152,000 to construct. In 1955 there were 258 men working at the coalfaces at this colliery, in 1956 this figure had dropped to 219 men at the coalfaces, and in 1958 it was back up to 278 men at the coalfaces. The colliery had its own coal preparation plant (washery).

On the 16th of May 1956, the NUM Safety Inspector visited the Training Face at this colliery and was appalled at the condition of the airways. In the return airway, he crawled on his hands and knees for one hundred yards but failed to get through and had to enter the district by another route. By 1958 miners were beginning to realise that there were easier and better-paid jobs elsewhere and in 1958 this colliery alone lost 126 men while in 1959 it still needed another 86 men to work to its full potential. This problem continued into the 1960s and although by October 1963 it had received men from the closed Bryn, North Rhondda and Garth Tonmawr collieries it was still seriously short of men, particularly in the South Pit.

In 1959 this colliery was working the 90-inch thick anthracite Six-Feet seam and from this seam, the methane gas was extracted and along with the gas from Duffryn Rhondda and Avon collieries, it was sent to the gas works at Aberavon and used to service 45,000 homes.

In 1961 it was still in the No.2 Maesteg Area’s, Afan Group along with Avon, Duffryn Rhondda and Garth Tonmawr collieries. The total manpower for this Group was 2,468 men, while the total coal produced for that year was 601,783 tons. The Group Manager was V.H. Evans and the Area Manager was W.B. Cleaver.

In 1969/70 the manager was T.M. Bond. The surface of the colliery was completely rebuilt in the late 1950s and early 1960s at a cost of £3 million with 100 contractors employed on surface reconstruction, and underground work exposing what was hoped to be 28 million tons of coal reserves, The coalfaces were longwall single units 120 yards in length which loaded onto conveyors and then locomotives hauling 1.5 ton mine cars to the pit bottom. The new winding engines could raise 360 tons of coal per hour. It was all too little avail, for the colliery was closed on the First of May 1970 on the dual grounds that it was uneconomic and its coal was unmarketable.

Some of the early fatalities at this mine:

- 8/12/1863, John Jones, Age: 44: Collier: Fall of coal.

- 25/09/1865, John Davies, Age: 21: Haulier: Fell under trams.

- 26/01/1867, W. Davies Age: 32: Collier: Fall of stone.

- 2/01/1868, John Rees, Age: 27: Collier: Killed by falling over the tip.

- 9/12/1874, T. Heslop: Collier: Killed by fall of roof.

- 3/03/1876, D. Davies, Age: 36: Collier: Killed by fall of stone.

- 28/11/1881, Daniel Lewis, Age: 44: Collier: Fall of roof.

- 8/04/1885, Levi Evans, Age: 35: Collier: Fall of roof.

- 29/11/1886, Charles Smith, Age: 54: Collier: Fall of roof from a smooth top and upright joint.

- 23/05/1890, Albert Curnwick, Age: 20: Collier: Drowned by an inrush of water.

- 14/09/1893, Thomas Vickers, Age: 64: Collier: Fall of roof at face (a bell stone 9ft. x 5ft. x 1 in. thick) while filling coal. No props set up. No.2 Rhondda seam.

- 2/08/1897, W.J. Gravell, Age: 15: Rope sheaver: Found dead on drum of small hauling engine, with rope coiled round his body. He had been working the engine in the absence of the engine man

- 19/3/1898, Thomas J. Jones Age: 39: Collier: Fall of side top coal. 10ins. x 30ins. x 18ins. thick fell while holing under it without sprags. Spine fractured and died 23rd Nov. No.2 Rhondda seam.

- 14/03/1910, A.E. Neath, Age: 24: Rider: While jumping on front of journey of trams leaving a parting he fell and was run over.

- 1/12/1910, Thomas Phillips, Age: 48: Wagon shifter: Struck on head by a piece of coal falling off a wagon.

- 3/11/1911, Edmund Jones, Age: 73: Hitcher: Died suddenly.

- 9/10/1912, David John Evans, Age: 25: Collier: Fall of roof – cut on head. Erisephylis set in.

- 6/03/1913, William Collins, Age: 65: Doorman: Died suddenly – verdict Natural Causes

- 29/04/1913, Edgar W. Powell, Age: 16: Collier boy: Fall of roof at working face. He was watching his comrade knock out some posts, before firing a shot, when the roof fell, killing him.

- 09/06/1913, Emrys Foster, Age: 26: Bratticeman: A tram broke away from a journey and ran back and killed him as he was walking out at the end of his shift.

- 22/05/1925, Edmund Jones, Age: 58: Collier: holing coal when clift fell – fatal skull fracture.

Some Statistics:

- 1897: Manpower: 181.

- 1899: Manpower: 181.

- 1901: Manpower: 53 on sinking operations

- 1902: Manpower: 36 sinking.

- 1903: Manpower: 77 sinking. Blaengwynfi: 264.

- 1905: Manpower: Blaengwynfi: 253. North Pit: 264. South Pit: 51.

- 1908: Manpower: 362.

- 1909: Manpower: 537. Blaengwynfi: 333.

- 1910: Manpower: 567. Blaengwynfi: 530.

- 1911: Manpower: 510. Blaengwynfi: 386.

- 1912: Manpower: 560. Blaengwynfi: 344.

- 1915: Manpower: Pits: 595. Levels: 480.

- 1916: Manpower: 400.

- 1919: Manpower: 440.

- 1922: Manpower: 450. Blaengwynfi: 550.

- 1923: Manpower: Pits: 454. Levels: 216.

- 1924: Manpower: 508.

- 1925: Manpower: 450.

- 1926: Manpower: 100.

- 1927: Manpower: 384.

- 1928: Manpower: 329

- 1932: Manpower: 250.

- 1933: Manpower: 592.

- 1937: Manpower: 784.

- 1938: Manpower: 995.

- 1942: Manpower: 720.

- 1944: Manpower: 561.

- 1945: Manpower: 634.

- 1947: Manpower: 695.

- 1949: Manpower: 833. Output: 170,000 tons.

- 1950: Manpower: 772.

- 1953: Manpower: 794. Output: 180,000 tons.

- 1954: Manpower: 772. Output: 156,217 tons.

- 1955: Manpower: 692. Output: 122,181 tons.

- 1956: Manpower: 669. Output: 106,438 tons.

- 1957: Manpower: 654. Output: 121,730 tons.

- 1958: Manpower: 637. Output: 151,320 tons.

- 1960: Manpower: 640. Output: 146,288 tons.

- 1961: Manpower: 531. Output: 135,832 tons.

- 1964: Manpower: 582.

- 1969: Manpower: 699.

- 1970: Manpower: 543.

Information supplied by Ray Lawrence and used here with his permission.

Return to previous page