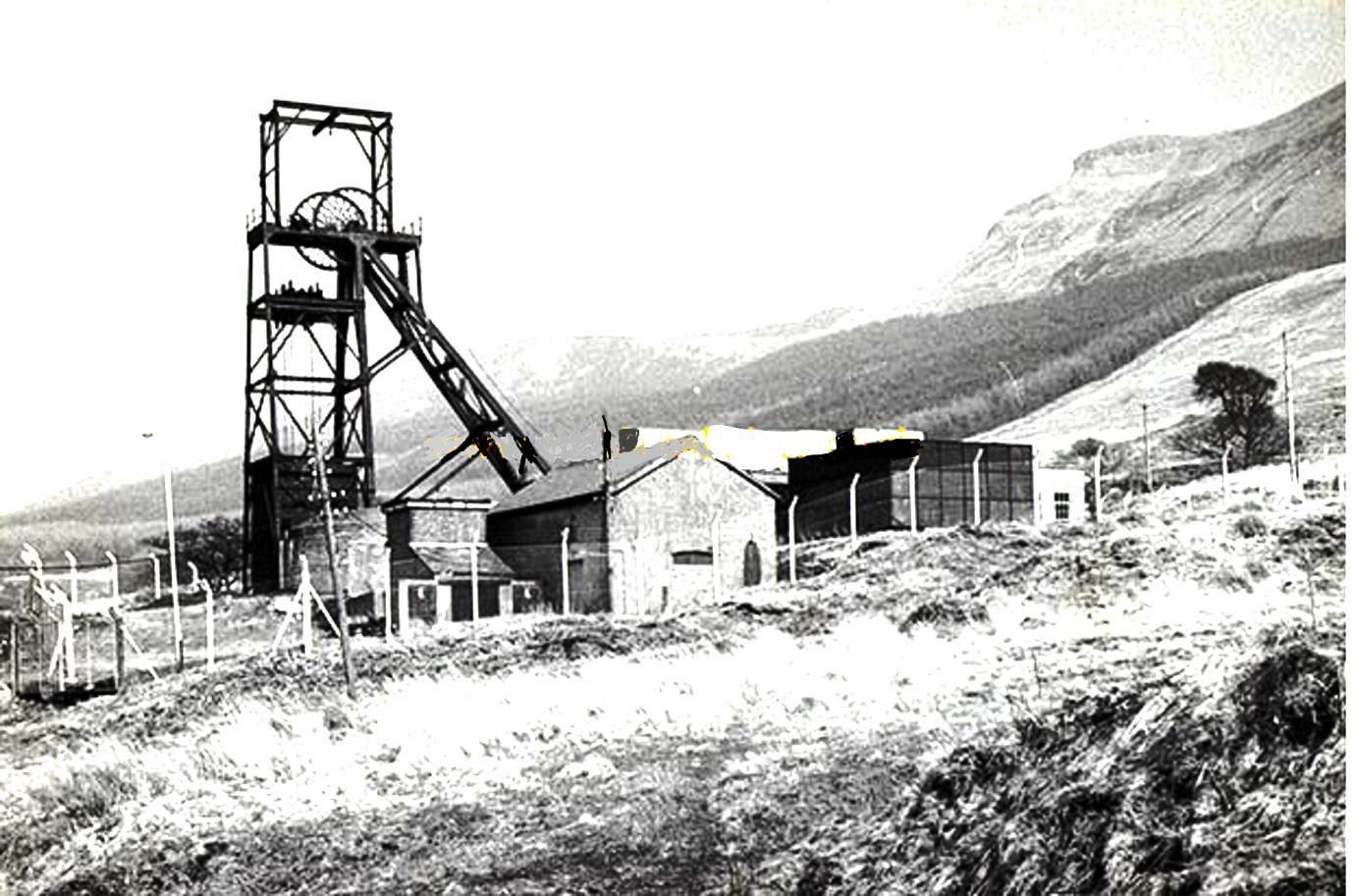

CWMGWRACH COLLIERY

Near Glyn-neath, Vale of Neath

Cwmgwrach Colliery was opened in 1898 by Empire Collieries Ltd. It produced Anthracite, Steam and Manufacturing coals mainly from the Six-Feet, Nine-Feet, upper Four-Feet and Bluers seams.

There is a long and sometimes confusing mining history in this area, the opening-up of the area for full exploitation followed the completion of the Vale of Neath Canal in 1795 several levels were driven with Edward Protheroe working the first Cwmgwrach levels in 1814. A tramroad connected the workings with the canal which at that point ran along the valley on the opposite side of the river. This tramroad was built on land belonging to the Pwllfaron colliery by William Gwyn who held a mortgage on the land owned by William Llewelyn. Protheroe had to pay a wayleave of 3d per ton to J. and D. Arthur of the Pwllfaron Colliery for the passage of coal over the tramway.

On the 9th of June 1820, an explosion at this colliery killed five miners, two of them were girls; Elizabeth Pendry aged 6 years and Annie Tonks aged 12 years.

By the time of the 1842 Royal Commission, this mine was in the hands of the local ironmasters, Messrs Jevons, Arthurs & Woods. It appears that the coal was not wholly used for their works, they also shipped it out from Giants Grave Wharf. Between the works and the mines, the children that they employed were:

- Trammers: 9 males and 1 female between 13 and 18 years, 2 males under 13 years.

- Colliers: 3 males between 13 and 18 years, 1 male under 13 years.

- Door keepers: 5 males under 13 years. The youngest is a boy of 9.

- Hauliers: 4 males between 13 and 18 years, 4 males and 1 female under 13 years.

- Cokers, fillers, iron burner and coal picker: 1 male and 3 females between 13 and 18 years, 2 males under 13 years. There is one boy of 9.

- Cutting chaff for horses and working on the farm: 2 females between 13 and 18 years.

- Attending masons and carpenters: 2 males 13 and 18 years.

The works and mines were described in the report as;

The new ironworks of Messrs. Jevons and Company in the Vale of Neath is the first or most eastern establishment of this kind met within the Stone Coal or Anthracite District and has as to present but one furnace in blast.

A tabular statement of the number of children and young persons at these works is given in the accompanying evidence and their employment and the circumstances of the works are described by W. Jevons, Esq., one of the partners:

The coal mine is ventilated by means of fire which produce a current of air which is conducted by means of doors through all the passages of the mine. Our works are entered by levels. The main ways are high enough for a horse. The beds of coal vary from 3 to 18 feet in thickness. The veins of iron ore are only a few inches thick but several veins are worked in one level.

Davy lamps are used in the coal mine but in the iron mines, they are not required. Firedamp and carburetted hydrogen gas exists in the colliery and chokedamp or carbonic acid gas in the iron mines but the accumulation of these gasses is prevented by good ventilation. In the colliery, the precaution is taken of sending a man with a Davy lamp through all passages of the mine to see that they are safe before the men begin their work.

One or two explosions have happened with some injury to the men but no loss of life. One man has lost his life within the period of two years by being run over by the trams or waggons on the railroad and another has lost a leg from a similar cause.

The coal and iron mined is drawn out in frames or wagons by horses along the main levels but boys between 13 and 18 years of age are employed to draw (single) such trams from the stalls to the main levels. The number so employed is about 10.

The boys employed as above draw by the band or with an iron hook. None draw by a belt and girdle. The distance they draw is about 50 yards. The weight of the waggon is about 4 cwt. The number of children and young persons is 35. drawing are as stated before. A few boys are employed to drive the horses in the trams or waggons in the mine.

There are no females employed in the mines except on rare occasions. Boys of seven are employed to shut doors that regulate the draft. Boys of 13 upwards are employed to drive. All that can be said as to their being necessarily required is, that boys of the above age can perform the work assigned to time as well as men could do it and of course at a much cheaper rate. The age of seven is certainly too early for children to begin to work. it is desirable that they should remain in school till they have acquired at least the rudiments of a good education, that is till 10 or 12.

The usual working hours are 10 hours of the same set. Children work the same hours as adults. They do not work at night in the mines. Our blast furnace is not suspended on a Sunday. The working of the furnace cannot be suspended even for a few hours without detriment. Such experiments of stopping the furnaces are too expensive to be tried. Only the furnace is at work on Sunday.

The colliers have no fixed time for their meals, except before and after their working hours. The other men have the usual interval for meals.

We have a school in connection work out works and it is supported by a general monthly contribution from the wages of the men to which they all give with their consent. The contribution of 6d. per month from all men, married and unmarried. Those who send their children to the school pay 6d. more for each child.

In 1858/60 Cwmgwrach was owned by R. Fothergill and in 1865/70 a Cwmgwrach was owned by N.V.E. Vaughn and in 1898 the Empire Collieries Limited (Blindell Bros and William & John Saville) re-opened Protheroes’by now closed Cwmgwrachlevels, sunk a new shaft, which was ten feet in diameter and 120 yards deep and was the upcast ventilating pit. They called the mine Empire. In 1903 this venture came under the Bryndu & Port Talbot Collieries Limited, (W.A. Blindell) they didn’t seem to have much luck with it for in 1904 & 1905 it was closed only to restart work in 1906. These mines then passed into the hands of the newly formed Caerbryn & Empire Collieries Limited by 1908 who shut down the older levels and concentrated work in the new Six-Feet (Cwmgwrach) Level. Based at Burrows Chambers in Swansea this Company employed 250 men at the mine producing anthracite coals in 1913. The manager at that time and up to 1915 was E.J. Bevan. In 1916 the manager was D.J.Rees. In 1918 it employed 309 men underground and 51 men on the surface the manager still being David Price. In 1914 the Company title changed yet again, this time to Cwmgwrach and Empire Collieries Limited who did not join the Monmouthshire and South Wales Coal Owners Association and were based at Bute Street, Cardiff. In 1934 the directors were T. Braithwaite, T.S. Braithwaite, Dr H.S. Forsdike, Mrs. Brockett-Grover and Mrs. A. Jones. This was its only mine at that time.

This company continued to expand, sinking another shaft in 1918, it was fifteen feet in diameter and 128 yards deep. This shaft was then used as the upcast ventilating shaft, and the old one turned into the downcast ventilating pit. They re-opened the Level Fawr in 1924, and the Level Newydd in 1927. The colliery had now changed the direction of its workings and was now moving eastwards producing steam and manufacturing coals.

In 1930 David Price was still the manager and this colliery was working the Nine-Feet seam. In 1934 the mine employed 130 men on the surface and 800 men underground. The manager was G. Rees. In 1943/5 the manager was still Mr. Rees and the mine employed 611 men underground working the Three-Feet, Nine-Feet and Six-Feet seams and 155 men on the surface.

On Nationalisation in 1947 Cwmgwrach Colliery was placed in the National Coal Board’s, South Western Division’s, No.1 (Swansea) Area, and employed 206 men on the surface and 715 men underground working the Nine-Feet, Six-Feet and Bluers anthracite seams. The manager at that time and in 1949 was E.G. Rees.

In May 1947, John Davies and Terence Jenkins, colliers at this pit set the United Kingdom record for coal cutting and filling when they produced 123 tons for a week from a nine feet thick seam. This was an astonishing sixteen tons more than the previous record. At that time Cwmgwrach had been exceeding its expected output by 300 tons a week for six months.

By 1954 this mine was in the No.9 Neath Area’s, Group No.1, and was working the Six-Feet anthracite seam employing 13 men on the surface and 489 men underground. The manager was H. David and this colliery had its own coal preparation plant (washery). The drastic reduction in surface manpower was due to the major re-organisation of the mines in this area that enveloped the Rock, Aberpergwm and Pentreclwydau slants, and the construction of a new washery at Aberpergwm, and eventually the sinking of the Blaengwrach New Mine.

In 1956 out of a total of 618 men employed at this colliery, 192 of them worked at the coalfaces, this figure dropped on slightly to 185 men at the coalfaces in 1958. A scheme to opencast 150,000 tons of coal in 1958 was shelved, only to re-emerge on a larger scale in 1995 against the express wishes of the local residents. In 1961 this colliery was in the No.4 Aberdare Area’s, No.2 Group along with Tower, Rhigos No.1, Rhigos No.7, Aberpergwm, Rock and Pentreclwydau collieries. The total manpower for the Group was 3,126 men, while the total coal produced in that year was 726,000 tons. The Group Manager was D.M. James, while the Area Manager was T. Wright. The Two-Feet-Nine seam at Cwmgwrach was 30” in thickness. The Six-Feet seam was up to 12 feet in thickness and was extensively worked. The Upper-Four-Feet seam only had limited workings while the No.2Rhondda seam was worked at a thickness of 44”. The Bluers seam was extensively worked. it had a section of coal 13”, dirt 5”, coal 26”. The Red Vein seam was 43” thick. The Nine-Feet seam was extensively worked and had a total thickness of up to 8 feet 8 inches. The Bute seam was 37” thick and the Gellideg seam was 48” in thickness.

Cwmgwrach Colliery was closed by the National Coal Board on the 13th of September 1963.

Some statistics:

- 1910: Manpower: 216.

- 1911: Manpower: 201.

- 1912: Manpower: 283.

- 1913: Manpower: 250.

- 1915: Manpower: 300.

- 1916: Manpower: 350.

- 1918: Manpower: 360.

- 1920/2: Manpower: 500.

- 1923: Manpower: 619.

- 1924: Manpower: 758.

- 1925: Manpower: 650.

- 1927: Manpower: 966.

- 1928: Manpower: 847.

- 1930: Manpower: 930.

- 1932: Manpower: 950.

- 1933: Manpower: 1,075.

- 1934: Manpower: 930.

- 1937: Manpower: 1,067.

- 1938: Manpower: 1,092.

- 1942: Manpower: 930.

- 1943/4: Manpower: 766.

- 1947: Manpower: 921.

- 1949: Manpower: 861. Output: 150,000 tons.

- 1950: Manpower: 863.

- 1953: Manpower: 838. Output: 182,300 tons.

- 1954: Manpower: 622. Output: 142.792 tons.

- 1955: Manpower: 664. Output: 142.312 tons.

- 1956: Manpower: 618. Output: 121.685 tons.

- 1957: Manpower: 532. Output: 83,438 tons.

- 1958: Manpower: 495. Output: 93,634 tons.

- 1960: Manpower: 448. Output: 100,000 tons.

- 1962: Manpower: 446.

Information supplied by Ray Lawrence and used here with his permission.

Return to previous page