Crumlin, Ebbw Valley (ST 2117 9880)

Crumlin, Ebbw Valley (ST 2117 9880)

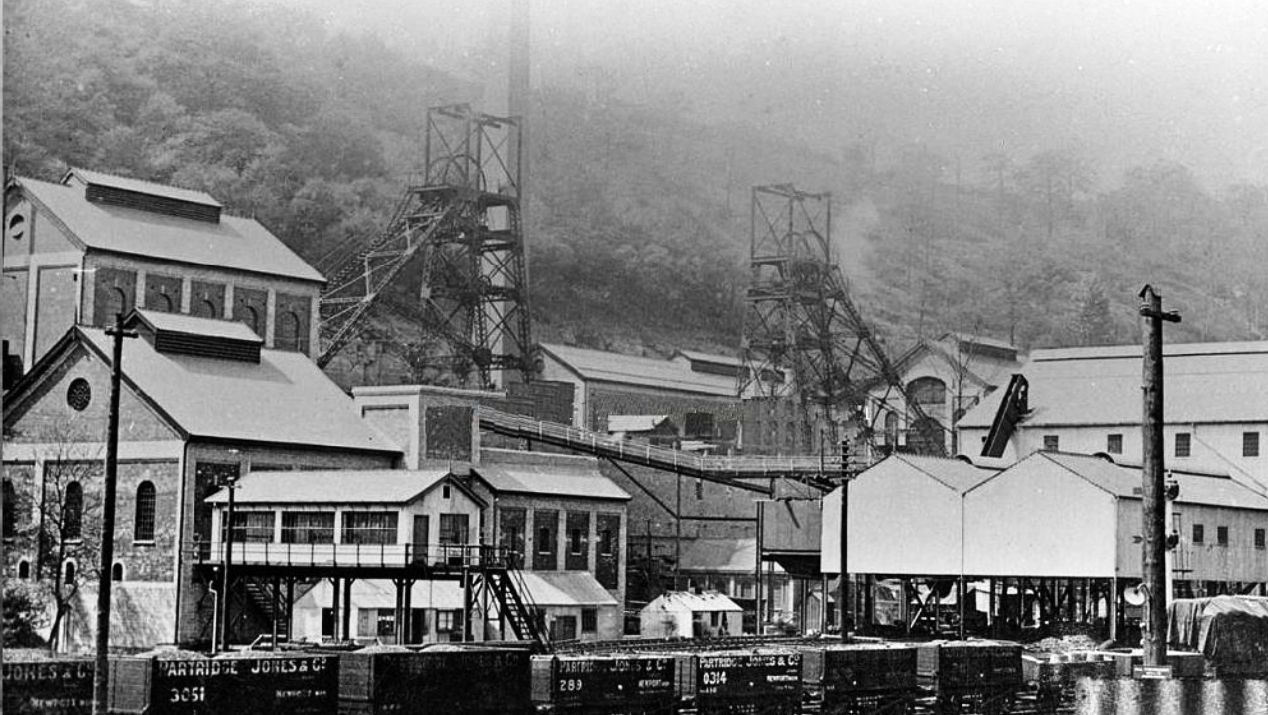

The sinking of the two shafts commenced in 1907 and was completed in 1910 to the Black Vein (Nine-Feet) seam. The downcast (North) shaft was 466 yards deep to the Black Vein. It was circular with a diameter of 20 feet and was the coal/materials/men winding shaft. The upcast (South) shaft was the same depth and diameter. The cages were single deck with two trams each with a maximum winding capacity of 700 tons per shift (North Pit). An unusual facet of this colliery was that blue pennant stone was used to line the shafts, this very expensive item being justified by the fact that virtually no repairs needed to be carried out during their working life. In July 1920 work commenced on sinking the No.2 pit another 70 yards to the Meadow Vein.

The Times of Saturday, 29th of October 1910, reported:

FATAL SHAFT ACCIDENT- While sinkers were working in the shaft of Messrs. Partridge, Jones, and Co’s., new colliery at Crumlin, Monmouthshire, yesterday, part of the staging collapsed and several men were thrown into the water at the bottom. One man, John Stone, residing at Newport, was drowned, and his body has not yet been recovered. Arthur Holder, of Cravelin-street, Llanhilleth, sustained a broken leg and the majority of the men, who numbered 20, received minor injuries.

The fan-house contained two Walker Bros horizontal twin tandem, four-cylinder triple-expansion steam engines. One is now with the National Museum of Wales.

The Times newspaper of Monday, 29th July 1929 reported:

Eight men were trapped by a fall of roof weighing about 100 tons in the Meadow Vein District. Joseph Walters of Hillside, Crumlin, was killed, Henry Clark of Bryncoed, Crumlin, and Ivor Smith of Backstone-road, Crumlin, was injured. The other five escaped unharmed. George Bevan who was working nearby escaped by holding up a little portion of the roof for two hours before being rescued.

There were further problems in 1932 when they went to open up a new district it was found that Oakdale Colliery had been ‘poaching’ coal belonging to its neighbour Crumlin Navigation Colliery. This was stopped and compensation paid, which resulted in 400 men being laid off at Oakdale.

The pit head baths were opened in February 1933 at a cost of £18,000. There were provisions for 800 men, with 140 cubicles, locker rooms, bottle filling facilities, bath attendants, boot cleaning and greasing room and a first aid room.

In 1935 Crumlin Navigation employed 86 men on the surface, and 358 men underground working the Meadow Vein (Yard/Seven-Feet), Black Vein (Nine-Feet), Elled (Two-Feet-Nine), Big Vein (Four-Feet) and the Three-Quarter (Upper-Six-Feet) seams. The manager at that time was V.Phillips. The main working districts were the East Black Vein District which stretched for four kilometres and the West Black Vein District which was 2.8 kilometres from the pit-bottom.

On Monday 6th June 1938, The Times newspaper reported that water had broken into the workings from an unknown source and flooded the mine. All the men had been withdrawn and work stopped. Steel and concrete dams were erected and new pumps were installed. The Black Vein Straight North District had hit an underground lake and the water eventually made its way to halfway up the shafts. Following emergency pumping operations the water was pumped out and the pit bottom was raised by 39 metres to accommodate a sump and extra pumping equipment.

During the Second World War, Crumlin Navigation was linked to the Celynen North Colliery to provide a way out for the miners if the surface of the mine was bombed.

Along with the nation’s other coal mines, Crumlin Navigation Colliery was Nationalised in 1947 and came under the National Coal Board’s South Western Divisions No.6 (Monmouthshire) Area which had its headquarters at Abercarn. This pit then employed 79 men on the surface and 336 men underground working the Old Coal (Five-Feet/Gellideg), Three-Quarter, Meadow Vein and Black Vein seams. The manager was W.G. Short.

The Coal News visited the colliery in 1950 and gave a glowing report:

Halfway up the narrow, 25 mile long Western Valley of Monmouthshire, stretching from Newport to Brynmawr, is the Crumlin Navigation Colliery, only a stone’s throw away from the massive Crumlin Viaduct which carries the railway over the River Ebbw from one side of the valley to the other. The viaduct has a part in the story of the colliery for it rests on valuable seams of unworked coal left beneath it to avoid subsidence.

As far as the South Western Division is concerned Crumlin Navigation is a middle-aged pit sunk in 1908 to a depth of 550 yards, it is in the south-west corner of three faults, known locally as the Trevethin, Oakdale and Llanhilleth faults, and if there is one thing more than another that is outstanding about this colliery it is the astonishing results that have been achieved in spite of severe geological conditions.

O.M.S. (saleable) before Vesting Day was 17-18 cwt, now it exceeds 30 cwt regularly and has exceeded the 31.1 cwt mark. How is it done? There is no secret – the answer is good management and unremitting effort from the men.

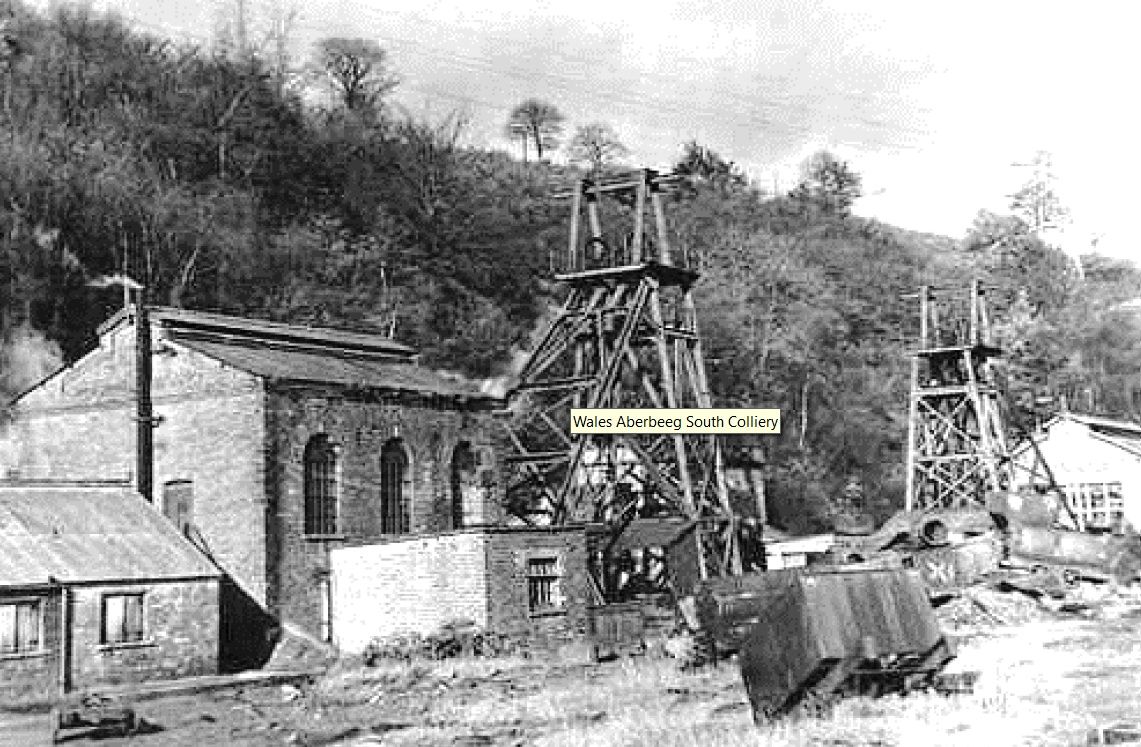

Known throughout the length and breadth of the valley is manager W.G. Short, who also manages the smaller Aberbeeg South Colliery a few miles further up. He came there in 1936 after 18 years at Six Bells and before that 8 years at Blaina, where his father worked for 38 years, latterly as manager.

Mr. Short learnt mining the hard way, as he will tell you, from his father who sent him into the pit to learn his trade from the bottom up, He will, however, be quick to add ‘And it has stood me in very good stead.’

Crumlin Navigation is a wet pit, and when I went there for a meeting of the Consultative Committee, combined, for the purpose, with that of Aberbeeg South. I was told that the pit was flooded in 1917. There was another inrush of water in 1939 – 200,000 gallons an hour – and the north part of the pit was damned off. It still is. They still have to deal with about 30,000 gallons per hour from the same source – the limestone beds beneath the Farewell Rock. ‘It is farewell to any more coal when you come to that rock.’

No account of consultative work at these two pits would be possible without reference to the dominant part played in it by Mr. Short. I met, amongst others at the meeting, Mr. J. Brookes, Miners Agent, NUM., Mr. David Bigham, a former member of Abercarn Council and secretary of Crumlin Lodge. Mr. Idris Pope, former chairman, and present member of Abertillery Council, and secretary of the Aberbeeg South Lodge. Mr. Martin Berrow, secretary of the consultative committee, and Mr. T.G. Evans, under-manager of Crumlin Navigation.

They all spoke in terms of the warmest praise for Mr. Short, his sagacity, ‘understanding and humanity’ He was, I was told, ‘accessible at all times, there is an ever open door here.’

Mr. Bigham gave me an instance; Take upgrading he said, as a result of joint discussions around the table, and facing the facts on both sides, the young men at this colliery know that they are getting a square deal. Said Mr. Brookes; ‘Consultative work here is a pattern for the remainder of the Area, I only have to come here about once a year to deal with matters that the manager has no power to deal with.’

Absenteeism is treated in the same way, ‘A heart-to-heart talk usually puts the matter right.’ Voluntary absenteeism is 6 – 9 %, and involuntary absenteeism 6 – 12%, below the average for the coalfield as a whole.

The consultative committee meets fortnightly in the manager’s office. At the one that I attended Mr. Short read the following letter from Mr. A. Tait, Area General Manager; ‘I am wondering if you did not think that I noticed that your output. Your December OMS 28.5cwt – an increase of 10.4cwt on the 1947 average and of 7.6cwt up on the pit average. The highest steam coal figure so far recorded in ay colliery in the Area. I would like to offer you, and everyone employed at the colliery, my sincere thanks and congratulations.’ As Mr. Bigham said,’ A feather in the cap of Crumlin Navigation.’

Another item concerned the division of the North Meadow Vein between Crumlin and Celynen North. ‘We were very perturbed at first’ said Mr. Bigham. ‘but we have to shed a parochial outlook if it is for the benefit of the industry as a whole.’ He amused the meeting by saying that since the division they had rats at Celynen North whereas there were none before. ‘That’s all right as long as they are not human.’ Remarked Mr. Short.

He could have paid no better tribute to his men than when he said;’ I have a fine lot and I wouldn’t change them for any in the valley. They have given me a hundred per cent cooperation and see that coal is filled in proper marketable condition. They realise that people pay a big price for it and feel that the consumer is entitled to a fair crack of the whip.’

How important that is will be seen from the fact that while Aberbeeg South produces loose coal from the Tillery seam, Crumlin Navigation works Black Vein steam coal, the finest in South Wales, more than 98% of which goes to the railways or for export.

In 1950 the NCB estimated that the reserves of coal available to this pit were:

- Big Vein: 1,434,000 tons.

- Three-quarter: 657,000 tons.

- Lower Three-quarter: 1,092,000 tons.

- Black Vein: 1,539,000 tons.

- Meadow Vein: 1,802,000 tons.

- Old Coal: 1,866,000 tons.

- Total: 8,390,000 tons.

In 1950 ventilation was by a steam-driven Walker type fan which produced 300,000 cubic feet per minute. The average amount of water pumped up the shafts per day was 412,000 gallons.

In April 1951 this pit’s output per man shift was 28.5 hundredweights which was 10.7 cwts higher than it was on nationalisation in 1947. It was the highest OMS recorded in a steam coal pit for this area at that time. In the 1950s, the annual output per miner was:

- 1955: 341.17

- 1956: 313.28

- 1957: 317.18

- 1958: 272.13

- 1961: 216.95

In 1956 out of the total colliery manpower of 430 men, 200 of them worked at the coalfaces, this figure dropped slightly to 198 in 1958, and further to 179 men at the coalfaces out of the 407 men employed at the colliery in 1961.

A survey of the reserves of coal left at the colliery in February 1958 showed that the Elled or Two-feet-Nine seam had not been proved. The Upper-Four-Feet or Big Vein had only been worked in a small area to the south-west of the shafts where it showed as 2 feet 4 inches of coal but the problem with this seam was that there was three feet of soft clod above the seam which was impossible to hold up. The next seam down, the Upper-Six-Feet or Upper-Three-Quarter had been worked on a small scale at a thickness of between 2 feet 4 inches and 2 feet 10 inches. The Lower-Six-Feet seam had not been worked and was a ‘dirty’ coal. The Nine-Feet or Black Vein seam had been the mainstay of the colliery and was virtually worked out. The report added that the lower coal may be left down “due to the difficulty of working.”

The West Meadow Vein Drift showed the Yard coal as being ten feet below the Black Vein and only 24 inches in thickness. Next down was the Meadow vein which showed top coal 34 to 37 inches, stone 1 inch, coal 24 inches, clod 11 inches, and coal 12 inches. A similar section was shown on the east side of the pit. The Old Coal (Five-Feet/Gellideg) had an average section of coal 28 ins, stone 1 ins, coal 24 ins, clod 11 ins, coal 12 ins and was another dirty seam. The top coal thinned down to 12 ins in parts and the stone between it and the next coal could thicken to 2–3 feet of ironstone.

Crumlin Navigation Colliery 1989

Copyright © Chris Allen and licensed for reuse under this Creative Commons Licence

Crumlin Navigation failed to survive the massive closure programme of the 1960s and closed on September 16th 1967.

The colliery buildings are deemed to be of outstanding architecture and are protected as listed buildings but the shafts were filled with washery tailings in January 1970.

There were 303 men employed on closure with 233 accepting transfers mainly to Tirpentwys 90, Celynen South 53, Marine 45, Llanhilleth 24, Celynen North 10, Six Bells 8 and Abertillery New Mine 3.

Some Statistics:

- 1908: Manpower: 356.

- 1920: Manpower: 236.

- 1924: Manpower: 576.

- 1925: Manpower: 525.

- 1926: Manpower: 690.

- 1927: Manpower: 313.

- 1929: Manpower: 739.

- 1932: Manpower: 313.

- 1935: Manpower: 444.

- 1938: Manpower: 479.

- 1940: Manpower: 571.

- 1942: Manpower: 571.

- 1947: Manpower: 415. Output: 87,000 tons.

- 1948: Manpower: 418. Output 94,000 tons.

- 1949: Manpower: 372. Output: 90,000 tons.

- 1950: Manpower: 418.

- 1953: Manpower: 435. Output: 149,000 tons.

- 1954: Output: 145,129 tons.

- 1955: Manpower: 422. Output: 143,976 tons.

- 1956: Manpower: 430. Output: 134,710 tons.

- 1957: Manpower: 434. Output: 137,657 tons.

- 1958: Manpower: 427. Output: 115,385 tons.

- 1960: Manpower: 391. Output: 87,000 tons.

- 1961: Manpower: 407. Output: 88,299 tons.

- 1962: Manpower: 410.

This information has been provided by Ray Lawrence, from books he has written, which contain much more information, including many photographs, maps and plans. Please contact him at welshminingbooks@gmail.com for availability.

Return to previous page