Pontypridd (05909088)

The old Tymawr shaft was part of the Great Western Colliery (please see the section on that colliery), and in 1896 employed 500 men underground and 104 men on the surface with the manager being William James. In 1908 it employed 876 men with the same manager and was working the Five-Feet and Lower Four-Feet seams. In 1897 it had a sidings capacity of 157 full wagons, 218 empty wagons, and 71 other wagons.

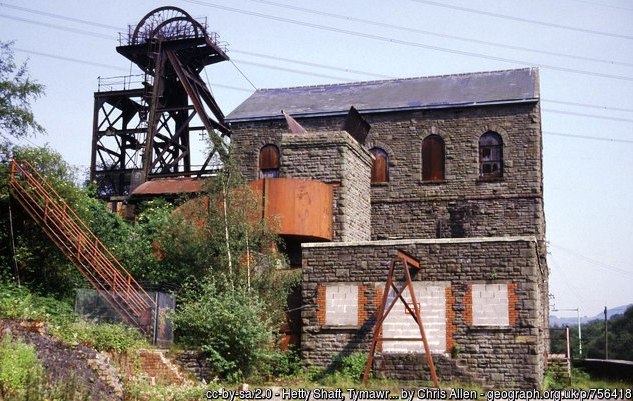

The new Ty Mawr shaft was sunk in 1923 by the Great Western Colliery Company Limited of Bristol on the closure of the Great Western Colliery. The Hetty pit was retained for pumping and ventilation purposes. The Great Western Colliery Company was a subsidiary of the Great Western Railway Company until it was purchased by the Powell Duffryn Steam Coal Company Limited.

During the sinking of the shaft, the following steam coal seams of the Lower and Middle Coal Measures were encountered:

- The Two-Feet-Nine seam with a section of 58 inches at a depth of 349 yards.

- The Four-Feet seam with a section of 77 inches at a depth of 365 yards.

- The Six-Feet seam with a section of 8l” at a depth of 392 yards.

- The Red Vein seam had a section of 40 inches at a depth of 409 yards.

- The Nine-Feet seam with a section of 68 inches at a depth of 421 yards.

- The Lower-Four-Feet seam with a section of 76 inches at a depth of 442 yards.

- The Five-Feet seam with a section of 86 inches at a depth of 475 yards.

This pit was hit hard by the slump in the coal trade and in July 1929 all bar 160 of the 700 workforce were laid off. The ones who stayed were used to open up the Lower-Four-Feet seam.

This company was a member of the Monmouthshire and South Wales Coal

Colliery Company Limited was based at 1, Great Tower Street, London with the directors being: Edmund Lawrence Hann, William Reginald Hann, Sir Francis Kennedy McClean and Evan Williams. It controlled three collieries and employed 2,270 miners who produced 650,000 tons of coal. By 1935 it was in the hands of Powell Duffryn and employed 90 men working at the surface of the mine and 580 men working underground. The manager at that time was D.J. Jones and in 1938 it was H.N. Forbes and in 1945 the manager was R. Rutherford. In 1943 it employed 488 men working underground in the Nine-Feet and Upper Five-Feet seams and 125 men working at the surface of the mine.

On Nationalisation in 1947, Ty Mawr Colliery was placed in the National Coal Board’s, South Western Division’s, No.3 (Rhondda) Area, No.1 Group, and at that time employed 109 men at the surface of the mine and 498 men working underground in the Nine-Feet and Upper-Five-Feet seams. The manager was still R. Rutherford.

In 1954/55 this colliery was one of 42 that caused concern to both the NUM and NCB over the high level of accidents. There was a marked increase in manpower by 1954 when 126 men worked at the surface of the mine and 734 men worked underground in the Upper-Nine-Feet and Upper-Seven-Feet seams. The manager was now R.J. Lankshear.

In 1955 out of the total colliery manpower of 850 men, 423 of them worked at the coalfaces, this coalface figure remained fairly stable throughout the late 1950’s only dropping to 401 men in 1958.

Ty Mawr Colliery was modernized in 1958 at a cost of £1.2 million and merged with the neighbouring Lewis Merthyr Colliery. One hundred contractors from Holts and Wimpey’s were employed on the surface reconstruction. The winding engine could raise/lower 50 men or 7 tonnes of material per wind.

In 1958 the price list for working in the Six-Feet seam (this colliery was now working this seam) was four shillings and sixpence (22.5 pence) for every square yard of coal extracted from the coalface.

In 1961 this colliery was still in the No.3 Area’s, No.1 Group along with Lady Windsor, Lewis Merthyr and National Collieries. The total manpower for this Group in that year as 3.157 men, while the total amount of coal produced by this Group in that year was 961,855 tons making it one of the most productive in the Coalfield. The Group manager was J.H. Jones while the Area Manager was G. Blackmore.

In the mid/late 1970s work was concentrated in a 12 square miles area of the Four-Feet and Upper-Nine-Feet seams. There were 21 miles of roadways in use including 3.5 miles of high-speed conveyors to take the coal to pit bottom. Four coalfaces gave an output per manshift of 2.9 tonnes at the coalface and 1 tonne overall for the colliery.

In 1981 this colliery still worked the Four-Feet and Upper-Nine-Feet seams, with coalface length varying from between 111 and 191 metres, with coal cutting by ranging drum shearers, and coalface roof supports either the self-advancing types or post and bars. Expected output per man shift on the coalface was 3.42 tonnes and overall for the colliery 1.13 tonnes. Manpower distribution was; working on the development of new coalfaces 70 men, working at the coalfaces 184 men, others working underground, 140 men, working at the surface 180 men.

Despite a major campaign by the South Wales Area of the National Union of Mineworkers, the failure to gather support in other Areas of the NUM for strike action meant that Ty Mawr/Lewis Merthyr Colliery closed in 1983.

Information supplied by Ray Lawrence and used here with his permission.

Return to previous page