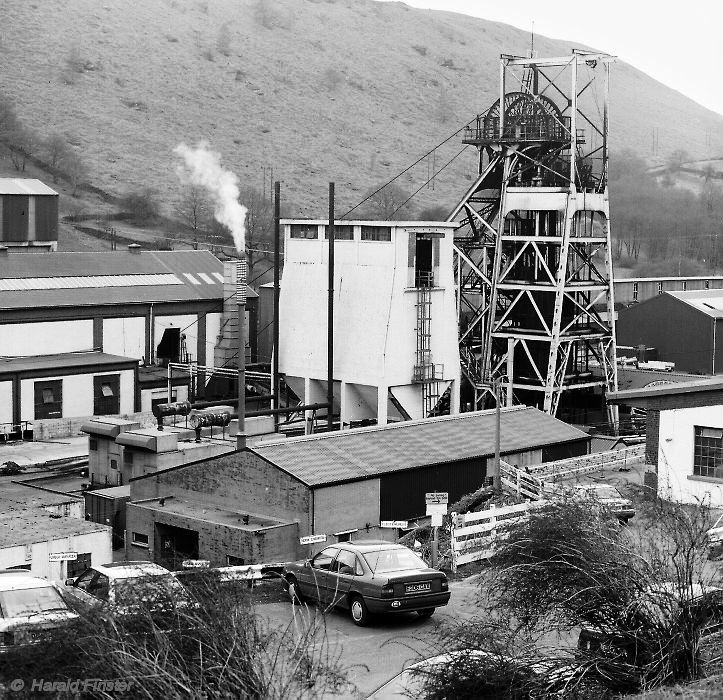

Taff Merthyr Colliery 1990

Copyright © Harald Finster and used with his kind permission

(Grid reference 10369900)

The sinking of the two shafts of this pit was carried out just under a mile to the north of Deep Navigation Colliery. The two shafts, the North and South pits, were 21 feet in diameter and sunk to the Four-Feet seam which it found at a depth of 1,903 feet.

They were sunk between 1922 and 1924, with production starting in 1926, this pit was one of the last major collieries to be sunk in South Wales under private ownership (it was a joint venture between the Ocean Coal Company and Powell Duffryn Steam Coal Company), and it was developed during the 1926 General Strike and Lock Out by members of the controversial South Wales Miners Industrial Union.

The Times newspaper of the 25th of January 1927 claimed that the miners were fed up with their union leadership after the 1926 strike and that the first branch established of the South Wales Miners Industrial Union appears to have been that at the Taff Merthyr Colliery where work was resumed long before the official termination of the strike.

Electricity was used at the colliery from the start, with the pithead baths being built in 1934. In 1926/1938 the manager was D. Hughes.

In January 1930 the company and men at this pit took out a life insurance scheme with the Metropolitan Life Insurance Company of New York. The contributions to the scheme were shared by SWMI, the owners and the men. For three pence per week, you qualified for £100 in the case of death of any cause, and if disabled you would receive 40 monthly payments of £2 12/6d. In January 1931 the miners at this pit who continued working during a South Wales miners strike received a £1 bonus from the company for their loyalty. At that time it was the only large colliery in South Wales without a SWMF branch.

The Times newspaper’s edition of the 24th October 1934 reported a sad event:

“After a search all night at Taff Merthyr Colliery, Treharris, Glamorgan, where a strike is in progress affecting 1,650 men, the body of Major John Ray Gibbon, 49, under-manager, was found in some disused workings at 7 am yesterday. Mr. Gibbon, who was in charge of the afternoon shift at the colliery, was last seen by a colleague at 4 p.m. on Monday. Death was apparently due to gas poisoning.”

The Taff Merthyr Steam Coal Company Limited was formed to run the pit. The chairman of the Ocean Coal Company, Lord Davies, was its chairman, and the chairman of the Powell Duffryn Steam Coal Company Limited, E.L. Hann, was on the Board. It was based at 11, Bute Crescent, Cardiff with the full list of directors in 1934 being; Lord Davies, Thomas Evans, Sir Henry Webb, Edmund L. Hann, Sir F.K. McLean and Sir Stephenson H. Kent. The company secretary was M.A. Anderson.

On Nationalisation in 1947, Taff Merthyr Colliery was placed in the National Coal Board’s, South Western Division’s, No.4 Area, Group No.4, and by 1954 employed 153 men on the surface and 874 men underground. It was working the Four-Feet seam. This colliery had its own coal preparation plant (washery) and was managed by R.T. Jones with the under-manager being H.G. Evans. In 1954 the manager was W.F. Hart and the under-managers were J. O’Brien and A.D. Laidlaw. At that time Taff was working the Four-Feet, Six-Feet and Nine-Feet seams.

In 1955 out of the total colliery manpower of 1,009 men, 507 of them worked at the coalfaces, in 1956 the coalface figure was 472 men, and in 1957 it was 431 men. In 1958 this colliery employed 429 men working at the coalfaces. In 1961 Taff Merthyr Colliery was still in the No.4 Area, No.4 Group along with Deep Navigation, Merthyr Vale and Trelewis Collieries. The total manpower for this Group was 3,398 men, while the total amount of coal produced by this Group in that year was 1,042,000 tons, the best in South Wales.

The NCB decided to invest in the future of Taff Merthyr in the 1950s, and in 1958, forty-four contractors from the firm Cementation employed their work on staple shafts and drivages.

The Times on the 14th of October 1966 reported:

“Eighteen miners were hurt in an explosion at Taff Merthyr Colliery, Treharris, Glamorgan, last night and eight were taken to hospital in Merthyr. Later six of them, severely burnt, were transferred to the St. Lawrence Plastic Surgery Hospital, Chepstow. The other ten miners were sent home.”

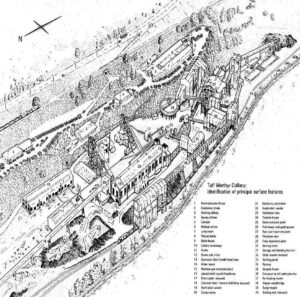

In 1970 Taff Merthyr was subject to review with a proposed closure towards the end of the year. In 1973 this pit was once again earmarked for closure but a major investment (£10.2 million) came in 1976 following the successful miner’s strike and shortage of oil. The shafts were deepened by 340 feet to the Old Coal (Five-Feet/Gellideg) seam, new pit bottoms were constructed, 1,400 hp winding engines and a skip in the north pit were installed with a capacity to wind 9 tonnes or 56 men. The surface of the colliery was completely renewed at £7.7 million with a new washery capable of washing 40,000 tonnes of coal constructed, with ‘merry-go-round’ trains being loaded from a 1,800-tonne bunker in 20 minutes. Work was concentrated on the Seven-Feet seam with the retreat method of extracting coal being used and with 2.5 miles of conveyors in use and 4.5 miles of roadways. Two coalfaces gave an output per manshift of 10 tonnes at the coalface and 3 tonnes overall for the colliery.

In the mid-1970s the NCB announced their intentions with regards to the collieries feeding power stations. They intended to concentrate production at three main units, one of them being the Taff Merthyr/Deep Navigation /Merthyr Vale Concentration Scheme. The reserves at Merthyr Vale were suitable for phurnacite production, and those at Taff Merthyr were suitable for power stations. With Deep Navigation, the western part of its take was suitable for phurnacite and the eastern part of the take for power stations. It was then proposed to wind only at Merthyr Vale and Taff Merthyr dividing the two types of coal between them. It was intended to retain Deep Navigation for manriding and materials. If the scheme had been completed it would have cost £9.2 million and produced an annual output of coal of 930,000 tons between the three pits, with an output per manshift of 2.5 tonnes.

In 1979 the B5 coalface was the best performing coalface in the South Wales Coalface in the 150cm to 179cm seam thickness group producing 1,117 tonnes of coal per day. In 1981 the pit was still working the Seven-Feet seam at a section of 129 to 162cm, with coalface length varying from between 142 and 250 metres long. Coal cutting was by ranging drum shearers and coalface roof supports were the self-advancing type. The B5 coalface was expected to advance by 2.4 metres per day on two coaling shifts which would give a daily tonnage of coal of 1,153. In February 1981 it had another 540 metres to run.

In 1979 the B5 coalface was the best performing coalface in the South Wales Coalface in the 150cm to 179cm seam thickness group producing 1,117 tonnes of coal per day. In 1981 the pit was still working the Seven-Feet seam at a section of 129 to 162cm, with coalface length varying from between 142 and 250 metres long. Coal cutting was by ranging drum shearers and coalface roof supports were the self-advancing type. The B5 coalface was expected to advance by 2.4 metres per day on two coaling shifts which would give a daily tonnage of coal of 1,153. In February 1981 it had another 540 metres to run.

The B20 coalface was expected to advance at a rate of 1.5 metres per day on a single coaling shift producing 904 tonnes of coal a day. It had a life of 112 metres. The B7 coalface was expected to advance at a rate of 2.54 metres per day on two coaling shifts giving a daily output of 980 tonnes. It had a life of 1,650 metres. The B21 was expected to advance at a daily rate of 3.7 metres on two coaling shifts giving a daily output of 1,370 tonnes of coal. It had a life of 600 metres. The B22 was expected to advance at a rate of 3.7 metres per day on two coaling shifts giving an output of 1,440 tonnes of coal. It also had 600 metres to run. The B6 coalface was expected to advance by 2.4 metres daily on a single coaling shift giving a daily output of 820 tonnes. It had 850 metres to run. Output per manshift on the coalface was expected to be 13.93 tonnes, and overall for the colliery, 4.23 tonnes. The saleable yield of coal was 80% of total production. The manpower distribution was; working at the coalfaces, 200, working at developing new coalfaces, 130, working elsewhere below ground 240, working at the surface of the mine 100 men. The manager at that time was G. Schewitz.

Despite further investment of £686,000 on the washery in 1982/3 in 1983, this colliery was losing £0.10 on every tonne of coal that it produced.

Following the 1984/85 miner’s strike this colliery made a remarkable recovery obtaining 92% of expected output within a month.

At a cost of over £10 million two coalfaces were equipped with high-tech equipment with 590 men producing 650,000 tonnes of coal from the Seven-Feet seam in 1988. In the week ending the 14th of May 1988, the pit reached the targeted 20,000 tons, but the period before that had been an anxious one with only the B23 district working between December and March. In September 1990 it set a Welsh output record for a week when the B24 Retreat Coalface advanced 234 feet 6 inches and produced 40,151 tonnes of coal for the power station market. However the pit couldn’t beat the dogma of a neo-liberal capitalist economy and Taff Merthyr Colliery was part of the mass closures announced by British Coal in late 1992 that caused such an uproar in Parliament, with public outcry and High Court Injunctions following in its wake, all to no avail, and by the time that confirmation of closure was made in May 1993, two-thirds of the men had already left. The final manager was R. Davies.

The last production shift was on the 11th of June 1993. Ryans Mining purchased the washery, and all attempts at a workers/management buy-out failed. It took 100,000 tonnes of various materials to fill in the shafts. On closure, 98 men lived in Treharris, 32 men in Bargoed, 28 men in Hengoed, and 26 men in Mountain Ash. 16 men in New Tredegar, 13 men in Rhymney, 12 men in Aberdare, 11 men in Pontypridd, 6 men in Caerphilly, 6 men in the Rhondda Valleys, 3 men in Bridgend, 2 men in Machen, 10 men in the Sirhowy Valley and 15 men in the Ebbw Valleys. Explosives were used to demolish the winding gear on the 22nd of July 1994.

Taff Merthyr Colliery worked the Four-Feet seam between 1926 and 1955. The Six-Feet seam between 1933 and 1972. The Nine-Feet seam between 1955 and 1971. The Seven-Feet seam between 1971 and closure. The Four-Feet seam averaged 67 inches, the Six-Feet seam 36 inches, and the Seven-Feet seam 53 inches. The Nine-Feet seam averaged; coal 30 inches, clod 18 inches, coal 54 inches. Its mineral take was bounded by the Rhos geological fault in the east and the Merthyr fault to the west. Based on the Nine-Feet seam this colliery’s coals were classed as type 201B Dry Steam Coal, low volatile, usually non-caking, low ash content (5% to 9%), low sulphur content (0.6% to 1.5%). The main uses were for steam raising in the boilers of ships, locomotives and latterly power stations.

Some Statistics:

- 1924: Manpower: 226.

- 1927: Manpower: 1,227.

- 1928: Manpower: 1,350.

- 1929: Manpower: 1,500.

- 1930: Manpower: 1,450. Output: 600,000 tons.

- 1931: Manpower: 1,600.

- 1932: Manpower: 1,500.

- 1933: Manpower: 1,743.

- 1934: Manpower: 1,650.

- 1935: Manpower: 1,620. Output: 600,000 tons.

- 1936: Manpower: 1,575. Output: 600,000 tons.

- 1937: Manpower: 989.

- 1938: Manpower: 1,112.

- 1940: Manpower: 1,575. Output: 600,000 tons.

- 1942: Manpower: 1,056. Output: 500,000 tons.

- 1944: Manpower: 1,075.

- 1945: Manpower: 1,119.

- 1947: Manpower: 994.

- 1948: Manpower: 1,032. Output: 319,000 tons.

- 1949: Manpower: 1,166. Output: 375,000 tons.

- 1950: Manpower: 1,057.

- 1953: Manpower: 1,049. Output: 354,000 tons.

- 1954: Manpower: 1,027. Output: 308,000 tons.

- 1955: Manpower: 1,009. Output: 289,845 tons.

- 1956: Manpower: 1,033. Output: 288,475 tons.

- 1957: Manpower: 1,042. Output: 286,485 tons.

- 1958: Manpower: 1,015. Output: 294,666 tons.

- 1960: Manpower: 905. Output: 271,000 tons.

- 1961: Manpower: 869. Output: 249,000 tons.

- 1962: Manpower: 936.

- 1969: Manpower: 920.

- 1970: Manpower: 840.

- 1971: Manpower: 676.

- 1972: Manpower: 681.

- 1974: Manpower: 685.

- 1978: Manpower: 692. Output:350,000 tonnes.

- 1981: Manpower: 740.

- 1984: Manpower: 681.

- 1987: Manpower: 681.

Information supplied by Ray Lawrence and used here with his permission.

Return to previous page