Crynant, Dulais Valley (78530333)

Crynant, Dulais Valley (78530333)

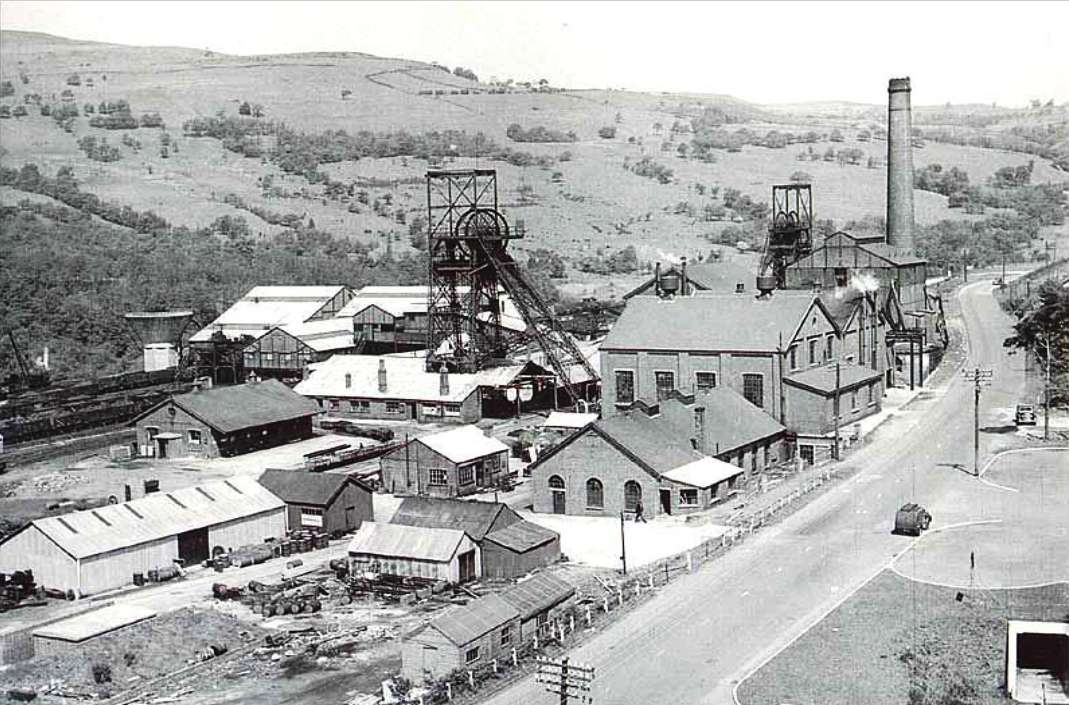

The owners of this colliery, the Llwyn-on Colliery Company Limited of Burrows Chambers at Swansea were opening the Llwynon Nos.1 & 2 in 1917, with the sinking of the Cefn Coed Colliery starting by 1921. For some reason sinking was then stopped until 1924 and was not completed until 1928. It was one mile to the south of Crynant. The surface screens were designed to take 200 tons of coal per hour while the washery could handle 150 tons of coal per hour and produce Large, cobbles, French nuts, stove nuts, small peas, cry duff, washed duff, large peas and pea nuts. The ventilating fan was a Walker Steart propeller type and was nine feet in diameter and could produce 190,000 cubic feet of air per minute.

The No.1 Pit (upcast ventilation shaft) was sunk to the Four-Feet White seam to a depth of 2,094 feet, the No.2 Pit was sunk to the Eighteen-Feet seam which it encountered at a depth of 2,106 feet 1 inch. At this time it was claimed to be the deepest anthracite mine in the world. Both shafts were 20 feet in diameter. The headgear on the downcast shaft was 65 feet high to the centre of the 18 feet diameter sheaves. The steam engine was made by Worsley Mesnes and had two cylinders of 32 inch diameters and a 60 inch stroke. The cages were single deck and could hold two 1.5 ton trams. The upcast winding engine was a Markham type with the cylinders being 32 inches in diameter and with a 72 inch stroke. The winding drum was conical in shape varying from 13 feet to 18 feet in diameter. In vertical total this pit had 72 feet of coal, of which 46.5 feet was in seams of more than two feet in thickness. The Graig seam was 34” in thickness. The Gorllwyn was 25” thick. The Two-Feet-Nine was 42”. The Upper-Four-Feet seam was 33” thick. The Six-Feet seam was 33” thick. The Red Vein seam was only 15” thick. The Dulais was top coal 25 inches, clod 4 inches, bottom coal 26 inches, with clift roof and fireclay floor. The Nine-Feet had a rock roof with the top coal being 12 inches, then a thin parting and a bottom coal of 48 inches. The floor was hard fireclay. The Peacock was 42 inches thick.

Although sunk to the Four-Feet seam it was opened out in a way so that the seams below this one, the Dulais, Nine-Feet and Peacock could also be developed. The coal seams dipped 4 inches to the yard to the south of the shafts so the South Drift was opened up at 9 inches to the yard while the North Drift was driven down at 6 inches to the yard dip until three seams were struck. Both roadways were supported by 14 feet arches with the haulage engine for the South Drift being an Uskside single drum 300 hp engines and for the North Drift it was a 140 hp Main and Tail type. All other haul aging was down by either compressed air haulages or pit ponies. The No.1 Pit and upcast shaft was the winding pit for the north side and the No.2 or downcast shaft was the winding shaft for the south side of workings.

The system of coalface working at this colliery was longwall in which gate roads would be driven into the coal twelve yards apart and the coal worked between them and thrown to the gate ends and then loaded in to trams. Roof supports in the Dulais and Peacock seams were steel props but due to its changing thickness timber props and steel bars were used in the Nine-Feet seam. As with most of the smaller colliery company’s in the anthracite section, the Llwyn-on Company was taken over by Amalgamated Anthracite Collieries Limited in 1928.

On the 4th of January 1929, John Lewis, a sinker, aged 53 years, died when he fell down the shaft.

Due to the depression in the coal trade it lay idle in 1934. The manager at that time was J.O. Howells. In 1943/5 the colliery was active again employing 689 men underground in the Dulais, Nine-Feet, Big, Peacock and Eighteen-Feet seams and 219 on the surface with the manager being T.J. Howells.

Along with the Nations other coal mines, Cefn Coed was Nationalised in 1947 and came under the National Coal Board’s South Western Divisions No.1 (Swansea) Area and at that time was working the Dulais, Peacock, Eighteen-Feet and White Four-Feet seams employing 613 men underground and 213 men on the surface. The manager was T.J. Howells. It had its own coal preparation plant (washery). The manager in 1949 was G.E. Roblings. The NCB promptly embarked on a major reconstruction scheme at the colliery at a cost of £400,000 driving to a new area to the north of the shafts in such a way as to cut through all the seams available for working. In 1954/55 this colliery was one of 42 that caused concern to both the NUM and the NCB over the high levels of accidents. By 1954 the Swansea Area had proved too large to administer and the No.9 (Neath) Area had been formed and Cefn Coed was placed in the new area. In 1956 out of a total of 746 men employed at this colliery 317 of them worked at the coalfaces. The coalface figure continued to drop throughout the life of this colliery, it being 273 men on the coalfaces in 1958 and 211 men out of the total of 552 men employed in 1961.

Both the reconstruction and re-organisation made little improvement on the colliery and in 1959 the pit was partially closed and half of the manpower was transferred or made redundant. From a total manpower of 734 in 1958, the pit had to lose 276 men from underground and 104 on the surface due to uneconomic results but in 1959 it was still losing £5.1s.8d per ton of coal produced. In 1961 this colliery was in the No.9 Area’s, No.1 Group along with Blaenant, Glyncastle and Ffaldydre collieries. The total manpower for the Group was 1,285 men, and total coal production for that year was 267,704 tons. The Group Manager was H. Jarman and the Area Manager C. Round.

This pit was earmarked for closure in 1967 but a remarkable campaign was launched that involved, Ifor Davies, the Secretary of State for Wales, taking a petition signed by 51,500 people to the then prime minister Harold Wilson. Wilson, on a tour of South Wales in February 1968, stated that the NCB were wrong to attempt to close the pit the following March. In view of this the NCB stated that they had deferred a decision on closure for another month.

Cefn Coed Colliery which was also the site of Blaenant Drift was closed on the 20th of April 1968 due to bad geology and is now a Steam and Mining Museum. It lost £400,000 in its last year of production.

On closure the men that wanted to were transferred to Blaenant, Blaengwrach, Brynlliw and Abernant collieries. Seventy men over 55 years of age opted for redundancy and 100 men were retained for salvage work.

Some Statistics:

- 1927: Manpower: 135 sinking.

- 1928: Manpower: 182 sinking.

- 1931: Manpower: 900.

- 1933: Manpower: 1,200.

- 1937: Manpower: 1,139.

- 1942: Manpower: 923.

- 1943: Manpower: 908.

- 1944: Manpower: 877.

- 1947: Manpower: 826.

- 1948: Manpower: 810. Output: 180,000 tons.

- 1949: Manpower: 810. Output: 200,000 tons.

- 1950: Manpower: 826.

- 1953: Manpower: 828. Output: 144,500 tons.

- 1954: Manpower: 754. Output: 83,886 tons.

- 1955: Manpower: 852. Output: 80,710 tons.

- 1956: Manpower: 746. Output: 102,844 tons.

- 1957: Manpower: 759. Output: 106,115 tons.

- 1958: Manpower: 734. Output: 113,613 tons.

- 1960: Manpower: 520. Output: 79,544 tons.

- 1961: Manpower: 552. Output: 87,933 tons.

- 1965: Manpower: 882.

Information supplied by Ray Lawrence and used here with his permission.

Return to previous page