OAKTHORPE COLLIERY (SK 331139)

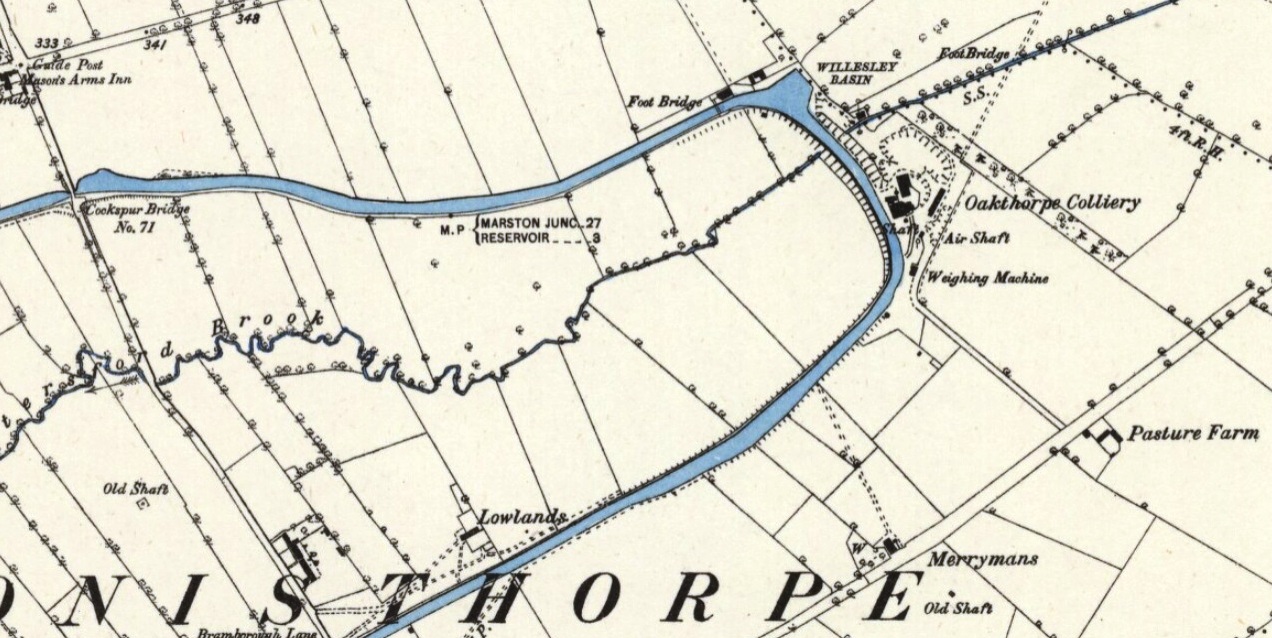

OS Map, Derbyshire LXIII.NE 1881

Reproduced by permission of the National Library of Scotland

Mining of coal was being carried on around Oakthorpe by 1600 if not before. These workings were at shallow depth and it was one Joseph Wilkes of Measham Manor who first sank a deep shaft at a location north of Oakthorpe village in 1787. Boreholes had been put down and these had located the Main Coal seam at 120 yards from the surface.

Wilkes went to Boulton & Watt for a winding engine which was erected by Boulton & Watt’s men with some assistance from Wilkes’ own craftsmen. The cylinder appears to have been obtained from John Wilkinson of Bersham, which was the usual practice of Boulton & Watt as they had no means of boring cylinders to the required accuracy. John Wilkinson had the field in cylinder boring technology at that time. The engine was rated at 8 horse power and was purchased for £500. Extra to this was an annual premium of £40 payable to Boulton & Watt for the use of their separate condenser engine.

This particular colliery at Oakthorpe was closed about 1810 and mining ceased until 1853 when a new lease was granted to one Benjamin Gibbons. He sank two new shafts close to the Ashby-de-la-Zouch canal near Willesley Basin. The Main Coal seam was reached at approximately 112 yards from the surface and was 14ft. 9in. thick at this locality. It may have been the success in finding coal in an area previously worked out by shallow pits which led local residents to call the new colliery “Who’d a’ thowt it!” Although this was very promising the colliery was plagued by gob fires caused by spontaneous combustion and heavy makes of water from old workings. This proved too much for Gibbons and the colliery closed in 1856, being sold to the Moira Collieries in the following year. There were still problems, both legal and with water, and the colliery did not re-start until 1863.

Once it had got going, Oakthorpe proved to be quite a successful colliery although the problems of spontaneous combustion and with water continued to some extent. The colliery closed in October 1885 and was sold off by Lord Donington, the owner of Moira Collieries. The new owner worked the colliery to a small extent but the colliery had been run down, so much so, that the new owner sued Lord Donington.

Eventually, Oakthorpe Colliery became part of Donisthorpe Colliery and was used as a service shaft by Donisthorpe. By the 1950’s a steel headgear and an electric winder had been provided. During the 1970’s, miners working in the old goaf areas of the Main seam, near to the Oakthorpe shaft were using the pit head bath facilities at Donisthorpe itself and were being “bussed” to and from the old Oakthorpe Colliery. A flight of steps joined the two collieries underground.

| Seams Worked (1952) | Stockings and Woodfield |

| Workforce (1952) | Underground 891, Surface 236 |

| CLOSURE | March 1990 |

OAKTHORPE – UNDERGROUND FIRE IN A COAL SEAM

Illustrating the liability to spontaneous combustion of coal seams in Leicestershire was the outbreak of a major heating in a shallow seam at Oakthorpe in 1985. Some evidence of a fire was indicated to the south-west of the village in 1984 when some settlement was noted. The seam, approximately 13 feet thick, dipped at about 1 in 7 northwards beneath Oakthorpe village itself. The outcrop lay in the gardens of many of the houses on the southern fringe.

Considerable damage was done to property necessitating demolition in some cases. A temperature probe inserted to a depth of two feet in one garden recorded a temperature of 260 degrees Celsius. In another location dense smoke was emitted from a hole being dug for a new fence post.

A number of factors which could have initiated spontaneous combustion at this location are a possibility. The closeness of the coal seam to the surface could allow air to reach it through the overburden. This access would be over a considerable area due to the thickness of the seam. In this locality also were a large number of old workings, many or most of which would not have been recorded. These old workings would have disturbed the overburden allowing air to pass through. At the time of the fire, Donisthorpe Colliery was also working a shallow seam only 275 yards to the north of the site of the fire. This seam was being worked in retreat with total caving of the waste which has the maximum subsidence effect at the surface.

OAKTHORPE and the NEWCOMEN MEMORIAL ENGINE, DARTMOUTH

A very early Newcomen pumping engine was built for Griff Colliery, near Nuneaton, Warwickshire in 1714 and was at work by 1715. It had for that time, the usual brass steam cylinder which was supplied with steam by a Copper boiler. Two pumps were located in the pit shaft and the barrels of these were cast iron. A second engine was erected about 1719 but the colliery was not very successful and the lessees gave up in 1720.

New lessees of the colliery erected a third engine in 1725. It seems quite possible that this was actually a rebuild of the first engine with a new steam cylinder of cast iron being fitted.

The new lessees did not have much success at Griff Colliery either and mining virtually ceased in 1728. It is likely that the 1725 engine was sold to Oakthorpe in 1734. These Oakthorpe pits subsequently came into the ownership of Joseph Wilkes. This is the engine which appears to be the surviving Memorial Engine. The engine worked at Oakthorpe until 1821 or thereabouts when it came into the possession of Jonathan Woodhouse. He sold the engine on to the Coventry Canal Company by whom it was re-erected at Hawkesbury Junction, possibly with Jonathan Woodhouse carrying out the work. Its duty was to pump water from a well to supply the canal.

Various modifications were made to the engine during its lifetime. Perhaps the most obvious and important was the fitting of a “pickle pot” condenser below the cylinder. Other modifications include the provision of a more modern design of chains on the arch-heads of the beam, these chains replacing the old link pattern. There were also improvements to the valves and valve gear.

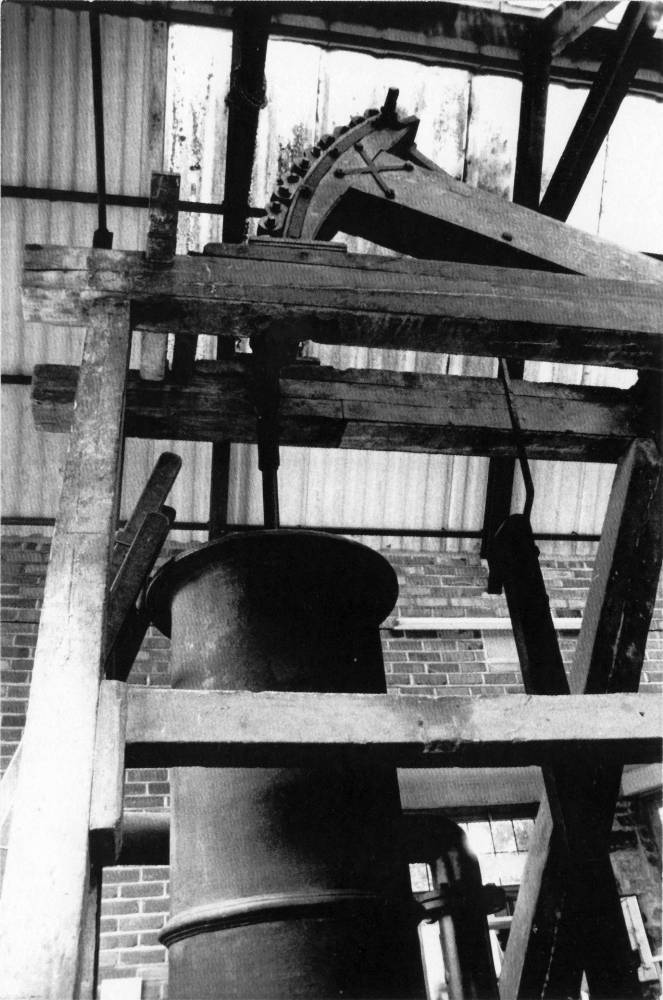

The Memorial Engine is a small one, certainly by late standards, having a cylinder 22 inches bore and a nominal stroke of 4 feet. Splayed timber posts support the ends of the spring beams upon which the beam is pivoted and a timber A frame structure provides additional support under the beam trunnions. This means that the engine is self-contained with no reliance on the engine house walls for support. Because this is a small engine the beam itself is quite light, consisting of a single member 9 inches wide by 15 inches deep. Length over arch heads is approximately 11ft. 6ins. Unlike old engravings of late surviving engines with wooden beams, there is no extensive trussing of the beam of the Memorial Engine.

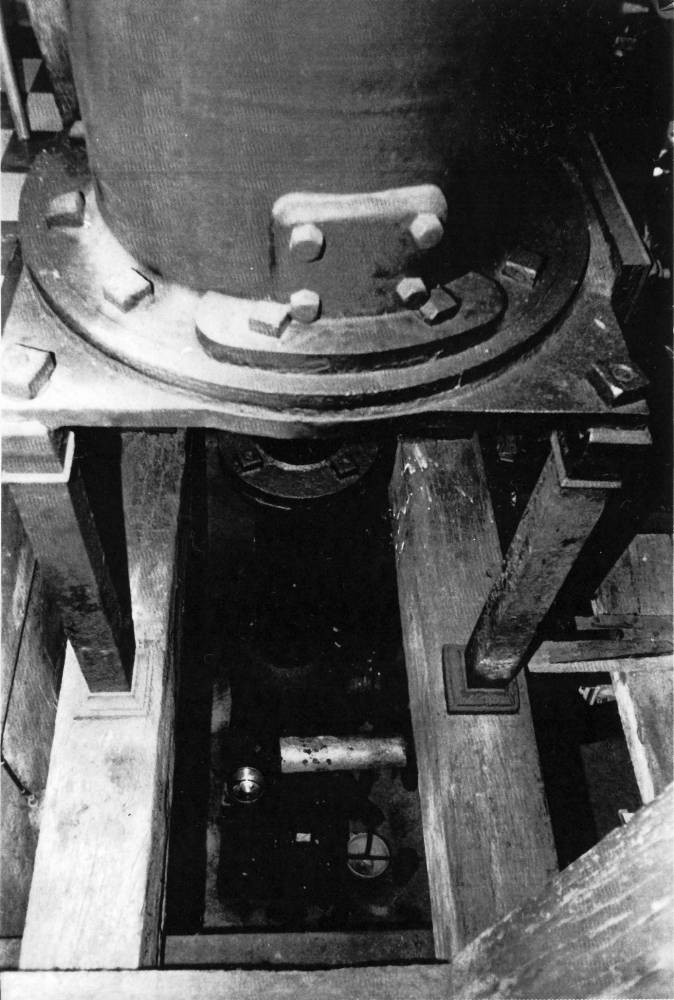

Pickle pot condenser fitted under the cylinder.

The internal injection sprayer is shown removed from the pickle-pot. Note the blanked-off connection on the cylinder.

Geoff Hayes 1977

A feature of the engine, mentioned above, is the “pickle pot condenser”. This device comprises a bottle shaped chamber located below the engine cylinder with the neck of the bottle in communication with the cylinder. On the upward stroke of the piston – the “outdoor stroke” – the pickle pot fills with steam as does the cylinder itself. Near the completion of the stroke water was injected into the pot instead of directly into the cylinder in order to condense the steam. The aim was to reduce the temperature fluctuations within the cylinder itself and thereby improve the efficiency of the engine. These devices were widespread and were fitted following James Watt’s invention of the separate condenser. Whether James Watt considered pickle pot condensers to be an infringement of his patent is not clear but he does not appear to have taken any action. A blanked-off aperture near the bottom of the cylinder of the Memorial engine may have been an original entry for the injection water pipe before the pickle pot was fitted.

Steam admission was through the bottom of the cylinder, the steam admission valve being separate from the cylinder and not bolted directly to it. A single arbor operates both the steam admission and the water injection valves through a rack and pinion system and a single handle actuated by adjustable slides or tappets on the plug rod, provided semi-rotary motion of the arbor. The injection water tank is at driving floor level, giving very little head over the pickle pot condenser. This may be a compromise in exhibiting the engine. A high level injection water tank would by usual. Bottom entry of the steam into the cylinder may indicate that the engine had the boiler under the cylinder in it’s mine pumping days. With such an early engine this seems very likely.

The engine was in service at Hawkesbury Junction until 1913 and then stood disused for 50 years. It was then presented to the Newcomen Society for preservation. Member Arthur Pyne undertook the dismantling and removal of the engine from Hawkesbury Junction and it’s re-erection at Dartmouth. At Dartmouth the engine can be operated by a hydraulic actuator.

Copyright © NMRS Records: Geoff Hayes Collection

Return to previous page