MEASHAM COLLIERY (SK 349119)

Measham Colliery, Minorca Shaft

Copyright © Mad About Mining and used with permission

Coal was being worked around Measham in the 1500’s. It seems likely that at least one Newcomen atmospheric pumping engine was at work in the 1720’s. The whole area became riddled with shafts and their associated shallow workings of which no records were kept at this time.

In 1856-57 the Moira company commenced a programme of exploration in the hope of establishing a colliery on modern lines at Measham. It was found that the area was already well worked and that the Main Coal seam varied quite widely in thickness. Two shafts, known as Abney’s, appeared to be the best proposition and they were sunk to about 100 yards. The seams intersected were the Main Coal (12ft. thick) at 25 yards, the Woodfield (5ft. thick) at 74 yards, the Stockings (8ft. thick) at 85 yards and the Eureka (4ft. thick) at 95 yards. Limited working in the Main Coal proceeded until 1862 but the colliery proved difficult to work and operations were suspended and it was used as a pumping station instead.

Measham Collieries Ltd was established in 1894 with the intention of working the Main Coal and other seams below such as the Woodfield and the Eureka. Now called Measham Main Colliery, it was linked by a tramway to a wharf on the Ashby De La Zouch Canal. Again, difficult working conditions were hampering progress and the Main Coal was abandoned in 1905. This had been preceded by the cessation of working in the Woodfield seam in 1902. In 1903 a total of 38,000 tons of coal were despatched by rail and canal.

By 1950 the National Coal Board had renamed the colliery as Measham.

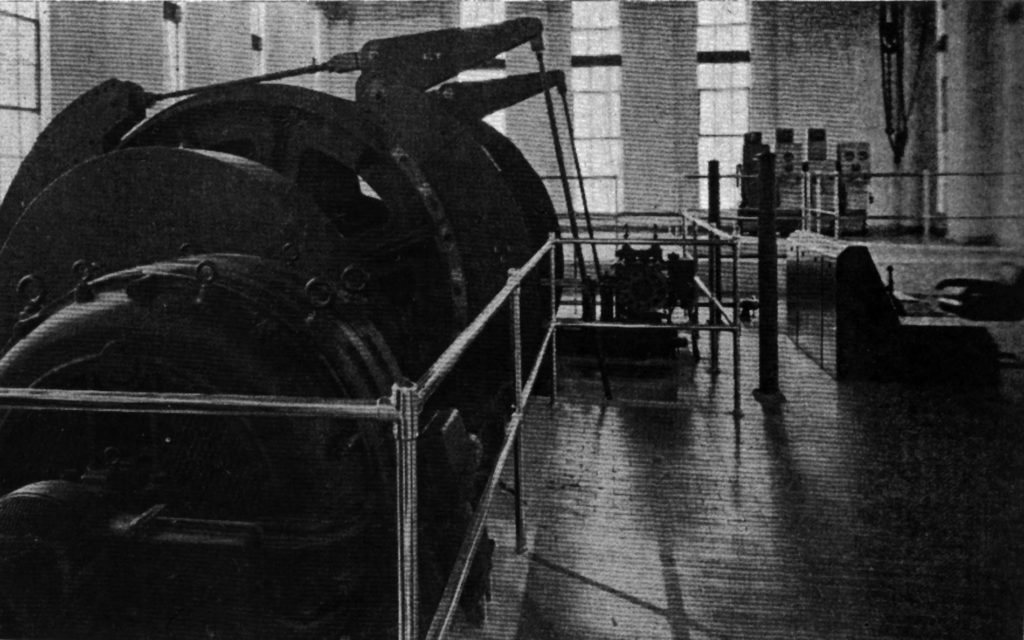

400 horse power electric winding engine by the English Electric Company, nearing completion of erection. Fitted with a Dynamic Braking system. c.1951. Colliery Engineering

Winding – No details of the steam winding plant has become readily available. About 1950 a 400 horse power alternating current 3-phase electric winding engine was installed. The electrical parts were made by English Electric and the mechanical components were by Fullerton, Hodgart & Barclay of Paisley. Dynamic braking was employed together with calliper type mechanical brakes for decking and parking. Overwind/overspeed protection was afforded by a Metropolitan-Vickers LILLY duplex controller. In the dynamic braking system the stator of the AC induction motor was disconnected from the alternating current supply and connected to a controlled direct current (DC) low voltage supply. With the mains supply to the motor “off” and the DC supply connected with the winder running as when approaching bank or alternatively lowering a heavy load, the motor acted as a generator thus giving a retarding effect. The amount of retardation was controlled by the driver’s lever which varied the amount of direct current passing to the stator of the motor. This method of control was effective down to about 1.5% of the normal speed, at which stage the mechanical brakes were brought into operation.

In the 1950’s the shaft was replaced for coal winding by a 1 in 4 drift, 370 yards long through which the trunk conveyor serving the underground workings was brought to the surface.

Underground Working – Longwall face working was being used as a method of extracting coal in the 1700’s at the pits in the Measham area and this continued until the cessation of working in 1986. At the more modern Measham Colliery, the area available for coal extraction – the “take” – was limited to the north by the workings of Donisthorpe Colliery. To the east the take was cut off by the Boothorpe Fault whilst to the south and west the seams outcropped. As the coal measures lay in a basin the angle of dip was quite variable. The trunk conveyor serving the underground workings was installed in a roadway running in the bottom of the basin.

In 1964, a retreat face was opened out in the Stockings seam about a mile from the shaft and lying at a depth of 90 yards from the surface. Close to the seam were two seams which had been previously worked. The Woodfield seam was approximately 14 feet above and had been worked in 1963. A 5ft. 4in. section of the seam had been extracted. Below the Stockings seam at a distance of 40 feet was the Eureka seam, 3ft. 9in. thick, which had been extracted in 1957.

The new retreat face in the Stockings seam was fully mechanised and was 224 yards long. The main face coal cutting machine was a 200 horse power Anderson Boyes (A.B.) Ranging Drum shearer. This was mounted on a panzer scraper chain face conveyor driven by two 50hp. motors, one at each end.

At each end of the face a stable hole was provided for manoeuvring the main face shearer. To form the stable hole at the supply gate end, an A.B.15, 70HP. chain coal cutter was employed, fitted with a 5 feet jib. The coal cut by this machine was hand loaded on to the face conveyor. The face conveyor delivered on to a 50HP. panzer conveyor which fed the main gate belt conveyor.

Face supports were Wild-Desford hydraulic goal post chocks and the stables were supported by Dowty hydraulic props and link-bar roof supports.

The Stockings seam was 7ft. 8in. thick in this locality, with a weak roof. For this reason 14 inches of coal were left up to form a roof with 6ft. 6in. of coal being extracted. The floor of the seam was soft, which when wet could cause problems with the roof supports sinking in.

High productivity was being obtained at the colliery at this time. About 600 men were employed, producing 600,000 tons of coal per annum, with an overall Output Per Manshift (OMS) of 85 hundredweight. (4.25 tonnes approx.)

Measham merged with Donisthorpe in March 1985, and the last shift was worked there on Thursday, June 26th 1986 (Burton Mail), with official closure on the following day.

See also Minorca Colliery.

OWNERS OF MEASHAM

1860-1861 Marquis of Hastings

1895-1896 W. Tate

1900-1946 Measham Collieries Ltd

1947-1985 National Coal Board

SEAMS WORKED AT MEASHAM

Main Coal 1900-1905, 1930-1940, 1950-1960

Eureka 1905-1920, 1950-1975

Woodfield 1908-1915, 1940-1967, 1980-1985

Stanhope 1910-1915, 1923-1940, 1950

Four Feet 1920-1925

Stockings 1940-1977

Kilburn 1964-1985

Thanks to Dave Spencer

Copyright © NMRS Records: Geoff Hayes Collection

Return to previous page