| COLLIERY | PARK (GARSWOOD) | ||||

|---|---|---|---|---|---|

| LOCATION | Approx. one mile east of Garswood station on LNWR St Helens – Wigan line. | ||||

| OWNERS |

|

||||

Park Colliery 1900

Taken in 1900 for the Mines Inspectors report. Pit brow women in shot. The wagons show you why the pit was locally known as Stones’s. Used with kind permission of Pitheadgear

Shafts

No.1 Pit (downcast), 13 feet diameter sunk 45 yards to Wigan Nine Feet.

No.2 Pit (downcast), 14 feet 6 inches diameter sunk to Arley Mine at 318 yards.

No.3 Pit (upcast) 14 feet 6 inches diameter sunk to Arley Mine.

Winding

No.1 Pit, twin cylinder horizontal engine 16 inches x 36 inches, teak cladding on cylinders, slide valves, parallel drum, 13 feet diameter, centre brake path. Two 7¼ cwt tubs per single deck cage. Winding ropes 3 inches circumference. 3 – 1 inches diameter charcoal iron wire rope conductors per cage.

Headgear of pitch pine 50 feet high, pulleys 10 feet diameter, pit landing bank 20 feet ht.

No.2 Pit, twin cylinder horizontal engine, 26 inches x 54 inches, by Wood & Gee, Wigan, 1888, Nos. 255 & 256, Eatock’s Patent slide valves, winding drum 15 feet 6 inches diameter, centre brake path. Cylinders clad in teak. Four tubs carried in double deck cages, Arley tubs 51 cwt capacity, Orrell Five Feet tubs 8¼ cwt capacity. Winding ropes 31 inches circumference, three 1¼ inches iron wire rope conductors per cage. Distance wound 323 yards, winding time 27 seconds.

No.3 Pit, twin cylinder horizontal engine 18 inches x 36 inches, slide valves, winding drum 8 feet diameter, brake path each side. One single deck cage carrying two tubs. Winding rope 3¼ inches circumference, two wire rope cage conductors. Winding engine used for lowering: Orrell Five Feet coal to Arley level for winding at No.2 Pit, and for emergency exit.

(1922) – New winding engine supplied by John Wood & Sons, Nos.3808 & 3809. Twin cylinder horizontal 21 inches x 42 inches, piston valves and independent drop cut-off valves, steam reverser, fast and loose winding drums, Mammoth-type bedplates.

Underground Haulage

Haulage engine located near top of No.3 Pit. Horizontal cross-compound engine, condensing, by Slee & Co., Earlstown, 1891, 20 inches + 36 inches x 48 inches, Double geared 1:71 to third motion shaft. Two pulleys for driving ropes, 8 feet diameter. Ropes taken down No.3 Pit to power four vertical shafts, one in each mine, each in turn powering a series of endless rope haulages.

Pumping

No pumping engine. Water wound in tanks at No.2 Pit as required.

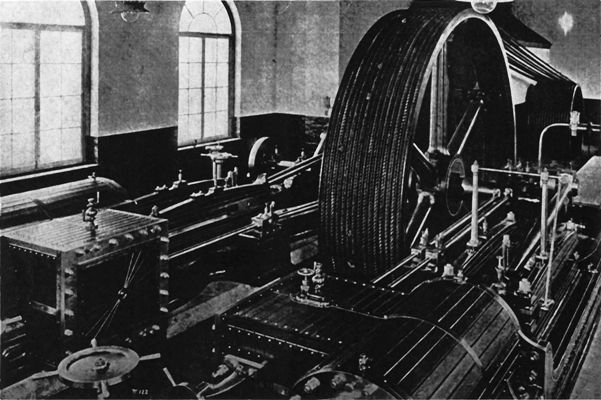

Park Colliery, Garswood

Cross-compound fan engine engine by Walker Bros. installed 1891

Ventilation

Walker “Indestructible” fan fitted with anti-vibration shutter. Fan 24 feet diameter by 8 feet wide, 262,925cfm. at 110rpm against 5 inches water gauge. Cross-compound horizontal engine 22 inches + 38 inches x 48 inches, vertical air pump driven from LP crankpin. Flywheel 16ft. dia., grooved for 15 – 15/8 inches diameter cotton ropes driving 7 feet 6 inches diameter fan pulley. Pipework arranged for condensing or non-condensing operation and either side operation singly if required.

Screens

Single cylinder horizontal engine 8 inches x 12 inches, by Wood & Gee.

Surface Lighting – Wenham gas lamps.

Boilers

Four Lancashire boilers 8 feet x 30 feet, five cross-tubes in each furnace tube. Made by Messrs. Heaton & Son, Holt Town, Manchester. 100psi. working pressure. Economiser to be installed shortly (1892).

Seams Worked

1892 – Wigan Four Feet and Wigan Nine Feet (by pillar & stall) Orrell Five Feet and Arley, worked longwall.

1933 – Wigan Five Feet, Wigan Four Feet, Wigan Nine Feet, Orrell Five Feet, Arley.

1954 – Ravine, Orrell Yard (Haigh Yard)

Workforce (1954) – U/G 677, S/F 146

NOTES – Walker Bros. supplied a portable belt drive compressor, 11 inches x 15 inches, in 1898. Air pressure 60psi.

2-10-03 – Walker Bros. supplied spares for 12 inches + 22 inches x 24 inches electric light engine, including LP expansion valves.

CLOSURE – 3 June 1960

Copyright © NMRS Records: G. Hayes Collection

Return to previous page