The shafts here were sunk on the site of earlier, shallower pits by William Jones & Co. The 3.2 metres diameter Oak pit was sunk to the Black Mine, at 227 metres, around 1848. The seam was 1.1 metres thick. The shaft was deepened to the Old Mine, at 353 metres, around 1909. From around 1850 the colliery was linked to Bradleybent canal basin by a self-acting inclined tramway. A tramway also ran to the nearby Brook Mill.

The Chamber fault was found to throw the measures down 503 metres on its south side, which increased the number of coal seams available for working. To do so, three cross-measures drifts were driven across the fault into the Roger Mine in 1911. One was for haulage, one for man riding and one for ventilation. Stratigraphically, the Roger Mine was above the surface at the Oaks shafts.

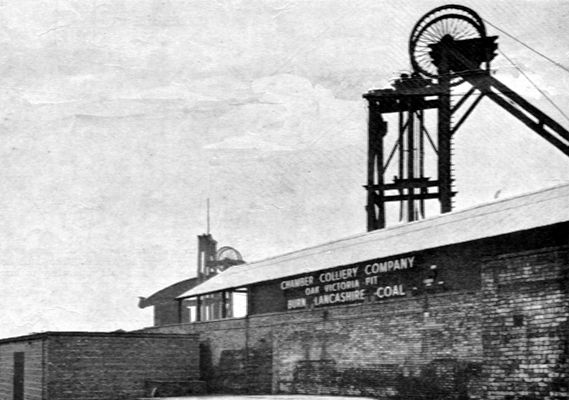

By 1859 the Chamber Colliery Co. was running the colliery. In 1877 members of the Lees family reformed the company as the Chamber Colliery Co. Ltd and worked Oak until it was Nationalised. Seven seams were worked:-

| Stratigraphical Order of Seams | Years Worked |

|---|---|

| Colonel | 1947-1956 |

| Roger | 1915-1950 |

| Furnace | 1947-1956 |

| Coney Green | 1910 – 0.97 m with a 0.1 m dirt band |

| Black | 1848-???? |

| Bent | 1890-1915 |

| Old | 1910-1950 |

Roger Haulage

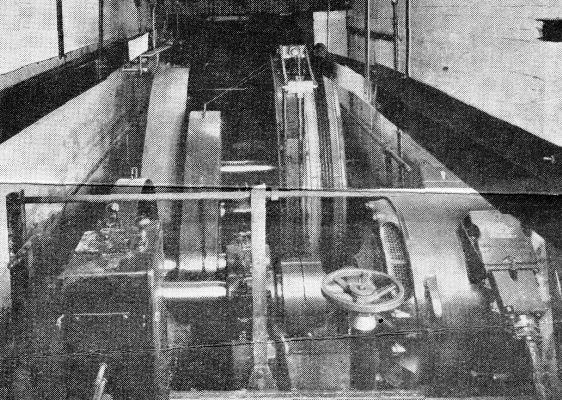

By the mid-1930s all the mines met in the shafts were nearing exhaustion, and preparations were made for working the downthrown coal more extensively. The surface plant underwent a major reorganisation in 1936. The electricity used was direct current, generated on site, but this was scrapped in favour of buying an AC supply from Oldham Corporation. The took demand off the boiler plant and allowed four to be scrapped, leaving two for daily use, one spare and a fourth was converted to a heat the feed water using exhaust steam. The two main Lancashire boilers would burn the dried slurry from the washery settling ponds. The steam engine driving the fan, a 1.96 metre diameter double-inlet Sirocco, was replaced by an electric motor. Another steam engine on the pit top, which drove the rope haulage serving the Roger Mine, was replaced by a 150 h.p. electric motor housed in the pit bottom area.

The National Coal Board continued working the Old and Roger Mines until 1950. The old steam winder was replaced by a renovated engine brought from Snowdown Colliery in Kent. An electric winder was installed for man-riding in the upcast shaft.

The NCB also worked the Colonel and Furnace mines, but it did not make major investments in the colliery. For example, power loading was not introduced. This was because the narrow shaft restricted winding capacity. As part of its policy of rationalisation, therefore, the Board decided to close Oak on July 13th 1956, and move its workforce to Bradford Colliery. The latter would work the Roger Mine left unworked by Oak.

Sources:

- NMRS Records, Gazetteer of British Collieries

- Fanning, G. Oldham Coal (British Mining No.68, 2001)

- National Archives: BT31/38187/11821 (1877) Chamber Colliery Co. Ltd

- Potts, E. “The Reorganisation of Chamber Colliery” Colliery Guardian, Vol.CIV, March 5th 1937, pp.433-438.