|

Northern Mine Research Society Registered Charity 326704 |

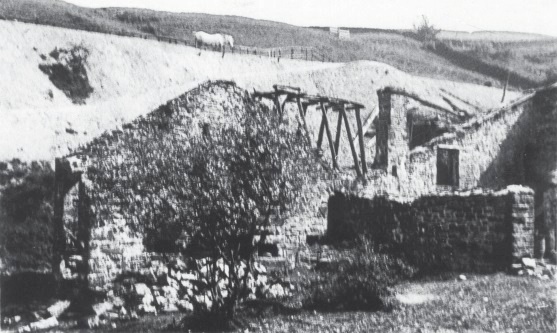

Cononley Mill

Cononley - SD 983465

This mill was built by the Duke of Devonshire c1840 to serve his mines on Cononley and Glusburn Moors. It closed in 1871. Any ore raised at the Cononley mine before 1840 or after 1871 was smelted at Grassington. In the 18th century, ore from the Glusburn mines was smelted at Lumb Clough mill, in Sutton.

Clough claimed that Cononley mill had two ore-hearths and a roasting furnace, but, in 1987, Gill questioned this and proposed that it only had one ore-hearth and a slaghearth. Whilst reviewing the evidence for this paper, however, even this latest interpretation came under doubt. It now appears that what Clough had described as a roasting furnace was, in fact, a reverberatory (smelting) furnace.

The evidence for this, whilst circumstantial, is as follows. Besides accounting for work at the slag-hearth, the mine ledgers only ever refer to work at, or on, a furnace. For example, in March 1851 the furnace was repaired. In November 1852, the smelters were paid for ‘making furnace bottom’ and ‘running bottom’. These terms are all more readily associated with a reverberatory furnace than an ore-hearth. Moreover, the only fuel bought by the mine was coal. Some of this was for the steam engine, but the rest must have been used in the smelt mill. Whilst coal was often blended with the other fuel burnt in ore-hearths, it is unlikely that it was used exclusively.

A double flue runs for 120 metres up the hill to a condenser where it unites and continues for 255 metres to the site of the original chimney. Around 1852 the flue was connected via Joy’s Level and its air shaft, to the present chimney near the summit of the Gib. This arrangement is unique, although in 1860 it was proposed extend the flue from the Kettlewell mill in a similar way through the Cam Level and up the Old Gin Shaft to a new chimney. This was never done.

The Cononley flue was periodically flushed by damming a boggy area to the southeast of the chimney with a low earth wall. The course of a leat from the dam to the chimney can be seen. In the 1960s, members of the Crosshills Naturalists Society and the Earby Mine Research Group repaired the chimney. The rather plain exterior hides a cunning method of achieving the required taper whilst maintaining strength; from its interior, one can see that the stonework has been corbelled.

Further information and references can be found in:

|

From British Mining No.33 © MC Gill |

Clough claimed that Cononley mill had two ore-hearths and a roasting furnace, but, in 1987, Gill questioned this and proposed that it only had one ore-hearth and a slaghearth. Whilst reviewing the evidence for this paper, however, even this latest interpretation came under doubt. It now appears that what Clough had described as a roasting furnace was, in fact, a reverberatory (smelting) furnace.

The evidence for this, whilst circumstantial, is as follows. Besides accounting for work at the slag-hearth, the mine ledgers only ever refer to work at, or on, a furnace. For example, in March 1851 the furnace was repaired. In November 1852, the smelters were paid for ‘making furnace bottom’ and ‘running bottom’. These terms are all more readily associated with a reverberatory furnace than an ore-hearth. Moreover, the only fuel bought by the mine was coal. Some of this was for the steam engine, but the rest must have been used in the smelt mill. Whilst coal was often blended with the other fuel burnt in ore-hearths, it is unlikely that it was used exclusively.

A double flue runs for 120 metres up the hill to a condenser where it unites and continues for 255 metres to the site of the original chimney. Around 1852 the flue was connected via Joy’s Level and its air shaft, to the present chimney near the summit of the Gib. This arrangement is unique, although in 1860 it was proposed extend the flue from the Kettlewell mill in a similar way through the Cam Level and up the Old Gin Shaft to a new chimney. This was never done.

The Cononley flue was periodically flushed by damming a boggy area to the southeast of the chimney with a low earth wall. The course of a leat from the dam to the chimney can be seen. In the 1960s, members of the Crosshills Naturalists Society and the Earby Mine Research Group repaired the chimney. The rather plain exterior hides a cunning method of achieving the required taper whilst maintaining strength; from its interior, one can see that the stonework has been corbelled.

Further information and references can be found in:

- Gill, M.C. Yorkshire Smelting Mills Part 2, Northern Mine Research Society Memoirs 1993, British Mining No 48, pp 132-151