|

Northern Mine Research Society Registered Charity 326704 |

Tan Hill Colliery and Kings Pit

The Tan Hill Coal, one of the most productive of the Dales seams, is often found near the top of the highest hills. Confusingly, the List of Mines placed the seam in the 'Limestone Series', which is wrong because it is in the Upper Howgate Edge Grit of the Namurian [Millstone Grit] series. The confusion probably arose because the pits produced 'Lime Coal' for lime burning.

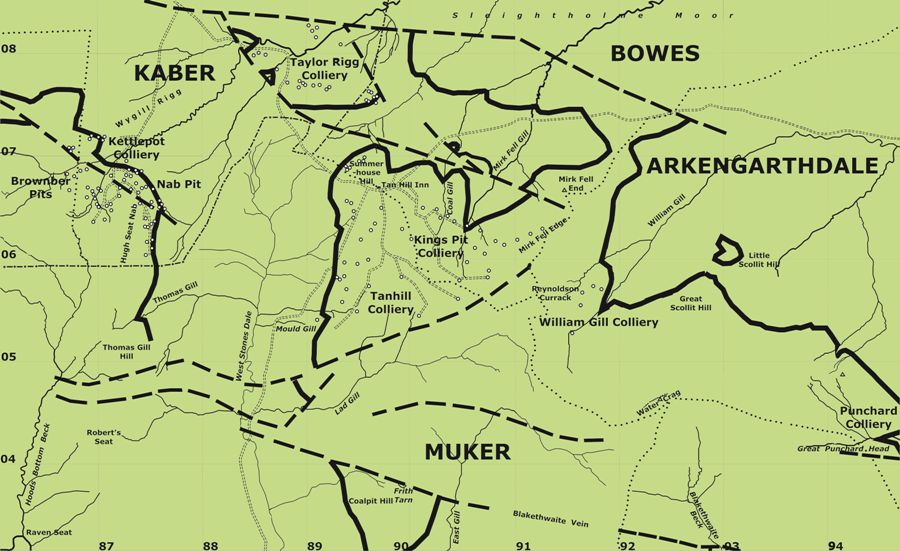

In the north of the study area what, for convenience, may be called the Tan Hill Coalfield includes mines in the townships of Kaber, Muker, Bowes and Arkengarthdale. The seam, which dips gently southwards, outcrops on the coalfield's northern edge, around Summerhouse Hill, into Coal and Mirk Fell Gills, then runs north-eastwards onto Sleightholme Moor where it ends against a fault. On the western margin of the Tan Hill Coalfield, the coal outcrops in West Stonesdale and runs south to a little north of Lad Gill, where it is cut off by faulting. There is a small outlier of Tan Hill Coal at Coalpit Hill, on Black Moor, on the south side of the Blakethwaite Vein.

Most pits in the Tan Hill Coalfield were sunk through peat and it was necessary to build a series of causeways across the peat to serve them. It is likely that such roads were floated on the peat because some of them shown on mine plans are no longer obvious because they are sinking, or have sunk. This problem is likely to be exacerbated by moves to reverse the extensive modern drainage of such peat lands.

The Tan Hill and Kings Pit Collieries, in Muker and Bowes respectively, worked a seam which was typically 30 inches (0.75m) thick, and with the following section:

The Tan Hill coal was described as a compact bright coal containing very little visible impurity. It was a mature coal, of relatively high rank, and was strongly coking, producing a highly swollen coke on carbonisation. Besides being used for domestic use and lime burning, around Tan Hill the coal coked easily and made a good fuel, but it lacked the heat of the William Gill coal. Many of the Tan Hill and Kings Pit shafts had cinder ovens for making coke. The lead smelters in Swaledale used coke for smelting lead slags, and blacksmiths probably swelled the market.

Top Coal 8 inches Dirt band 1¾ Bible Coal 6 Bottom Coal 16

Coal was being worked from shallow pits around the outcrop at Tan Hill by the 13th century and mining was abandoned in September 1938. Away from the outcrop, the coal was won from extensive board and pillar workings, served by a series of gin shafts with depths varying between 60 and 240 feet. The pillars were also worked periodically when, for a number of years, most of the production came from that source. The relative ease of working pillars, using existing gates, had to be offset against the expense of all the timber needed. Pillar removal also sometimes led to problems with 'Creep', where the weight of the collapsing roof (in worked out areas) crushed adjoining pillars into the underlying strata, causing the floor of the boards to rise up.

From 1843, drainage down dip was provided, for a time, by a steam engine on Gin Shaft. This was replaced by Mould Gill Level, which was driven up to the Low Gin Shaft in the early 1840s. In January 1854, a long branch of that level was begun. It was driven to the south-east and extended the mine's life by accessing coal further down dip.

Gill, M.C. "Great Dales Coalfield, Eastern Areas" British Mining No.86 (2008), pp.68-108